I-Welding steel stainless idinga ubuchule obukhethekileyo kunye nokulungiswa ngokucophelela ngenxa yeempawu zayo ezizodwa.Yenziwe ngentsimbi eshayinayoisetyenziswa kakhulu kumashishini afana nokulungiswa kokutya, amayeza, i-aerospace, kunye nolwakhiwo ngenxa yokunganyangeki kwayo okuphezulu, ukomelela, kunye nesibheno sobuhle. Nangona kunjalo, ezi mpawu zifanayo zenza kube nzima ukuwelda xa kuthelekiswa nentsimbi ethambileyo.

Kwesi sikhokelo, thina'Iza kugubungela imigaqo esisiseko yokuwelda intsimbi engatyiwayo, imiceli mngeni eyibonisayo, kunye nezona ndlela zilungileyo zokufikelela kwiiwelds ezikumgangatho ophezulu. Nokuba ungumqali okanye ungumdi onamava, ukuqonda ezi ngqikelelo kuya kukunceda ufumane iziphumo ezingaguqukiyo xa usebenza ngentsimbi engenasici.

IiPropathi zeNtsimbi engatyiwayo

Insimbi engenasici iqulethe ubuncinci be-10.5% yechromium, eyenza umaleko we-oxide we-passive kumphezulu, unika ukuxhathisa ukubola. Iindidi ezahlukeneyo zentsimbi engenasici, ezifana ne-austenitic, i-ferritic, i-martensitic, kunye ne-duplex, zibonelela ngeendibaniselwano ezahlukeneyo zamandla, ukuwelda, kunye nokuxhathisa ukubola.

Iipropathi zentsimbi engenastainless ezinefuthe kwiwelding ziquka:

Ukwandiswa kwe-Thermal High: Insimbi engenasici yandisa ngaphezu kwe-carbon steel xa ishushu, yandisa umngcipheko wokulwa kunye nokuphazamiseka ngexesha le-welding.

I-Low Thermal Conductivity: Ubushushu abuchithwa lula, bukhokelela ekugxininiseni ubushushu kwi-weld joint, enokubangela ukutshisa.

Uvakalelo kuBushushu: Ukufakwa kobushushu obugqithisileyo kunokubangela ukujika kombala okanye ukunciphisa ukuxhathisa kokuhlwa.

Ukubunjwa kweeCarbides: I-Chromium carbide formation ingenzeka kumaqondo aphezulu okushisa, ukunciphisa ukuxhathisa kwe-corrosion (into eyaziwa ngokuba yi-sensitization).

Iintlobo zeStainless Steel yeWelding

1. iAustenitic Stainless Steel (300 Series)

Iimpawu: Ayinamagnetic, ayinyangeki kakhulu kumhlwa, kwaye kulula ukusebenza ngayo.

Amabanga aqhelekileyo: 304 kunye ne-316.

I-Weldability: Ilungile, kodwa ithanda ukuphazamiseka ngenxa yokwanda kwe-thermal.

2. I-Ferritic Stainless Steel (400 Series)

Iimpawu: Imagnetic, ukuxhathisa okuphantsi kwe-corrosion kuneentlobo ze-austenitic kodwa i-thermal conductivity ephezulu.

Amabanga aqhelekileyo: 430.

Ukuweldability: Phakathi; ifuna unyango lobushushu lwangaphambili nasemva kwe-weld ukuphepha ukuqhekeka.

3. I-Martensitic Stainless Steel

Iimpawu: Amandla aphezulu, ukuxhathisa ukunxiba, kunye nokumelana nomhlwa okuncinci.

Amabanga aqhelekileyo: 410 kunye ne-420.

Ukuweldability: Kunzima; kufuna ukulawula ngononophelo ubushushu ukuphepha ukuqhekeka.

4. Duplex Stainless Steel

Iimpawu: Umxube weempawu ze-austenitic kunye ne-ferritic, ezinika amandla aphezulu kunye nokumelana nokubola.

Amabanga aqhelekileyo: 2205.

I-Weldability: Ifuna igalelo lobushushu eliphantsi ukukhusela i-embrittlement.

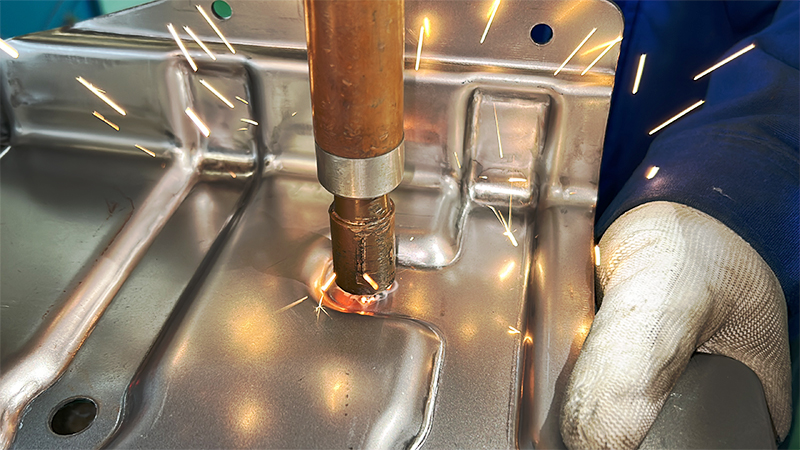

Iindlela zokuwelda kwintsimbi yentsimbi

Okona kulungileyo: Amashiti entsimbi ebhityileyo kunye nezicelo ezifuna ukuchaneka okuphezulu.

Iingenelo: Iiweldi ezicocekileyo, ezichanekileyo kunye nesitshizi esincinci.

Iingqwalasela: Ifuna umsebenzi onobuchule kunye nesantya esicothayo sokuwelda.

Eyona nto ibhetele: Iiprojekthi ezinkulu apho isantya sibalulekile.

Izinto eziluncedo: Ngokukhawuleza kune-TIG welding kwaye kulula ukuyifunda.

Iingqwalasela: Inokuvelisa i-spatter kwaye ifuna igesi yokukhusela (ihlala i-argon okanye ixube ne-CO₂).

Eyona nto ingcono: Iiprojekthi zangaphandle kunye neengxenye zentsimbi etyebileyo.

Iingenelo: Ayifuni't ifuna irhasi yokukhusela, iyenze ilungele umsebenzi wangaphandle.

Iingqwalasela: Kunokuba nzima ukulawula kwintsimbi ebhityileyo engenastainless.

Eyona nto ingcono: Amaphepha amancinci kwizicelo zeemoto kunye nezoshishino.

Izinto eziluncedo: Ukukhawuleza kwaye ngokufanelekileyo kumalungu awelanayo.

Iingqwalasela: Ilinganiselwe kwiintlobo ezithile ezidibeneyo.

IiNdlela eziGqwesileyo zokuWelding Stainless Steel

Ukulungiselela

Coca imiphezulu ngocoselelo ukususa ubumdaka, igrisi, kunye ne-oxidation. Izinto ezingcolisayo zinokubangela iziphene ze-weld kunye nokunciphisa ukuxhathisa ukubola.

Sebenzisa izixhobo ezizinikezeleyo (iibrashi, iigrinder) zentsimbi engenasici ukuthintela ukungcoliseka kwezinye iintsimbi.

UKhetho lweGesi yokuKhusela

Kwi-TIG welding, sebenzisa i-argon ye-100% okanye i-argon-helium mix.

Kwi-MIG welding, umxube we-argon kunye ne-CO₂okanye ioksijini iphucula ukungena kwe-weld kunye nokuzinza.

Lawula iNgeniso yoBushushu

Sebenzisa elona galelo lisezantsi lobushushu ukunqanda ukulwa, ukujika kombala, kunye nokwakheka kwekhabhide.

Ukuba kunokwenzeka, sebenzisa i-pulse welding ukulawula ukuhamba kobushushu ngokuchanekileyo ngakumbi.

Nciphisa Ukugqwetheka

Zibambe ngokuqinileyo izixhobo zokusebenza ukuze unciphise intshukumo ngexesha le-welding.

Sebenzisa i-backstepping (welding amacandelo amancinci kwiindlela ezitshintshanayo) ukusabalalisa ubushushu ngokulinganayo.

Ukucocwa kwePost-Weld kunye nokugqiba

Susa nakuphi na ukujika kombala ngeebhrashi zocingo zentsimbi okanye izicoci zeekhemikhali ukubuyisela ukuxhathisa ukudleka.

Sebenzisa ubuchule bokudlula ukususa ukungcoliseka komphezulu kunye nokwandisa umaleko weoksidi.

Ukunqanda iiNdaba kunye noKwazisa

Kumacandelo atyebileyo, ukufudumeza intsimbi kunokunceda ukunciphisa umngcipheko wokuqhekeka.

Sebenzisa amabakala ekhabhoni ephantsi (afana ne-304L okanye i-316L) ukuphepha ukubunjwa kwe-chromium carbide.

Iziphene eziqhelekileyo kwi-Stainless Steel Welding

I-Warping kunye ne-Distortion: Ibangelwa igalelo lobushushu obugqithisileyo kunye nokwandiswa kwe-thermal.

Burn-Through: Kwenzeka xa ubushushu bunyibilika kwizinto eziphathekayo, ezihlala zibonwa ngeentsimbi ezincinci.

Ukuqhekeka: Ngokuqhelekileyo ngenxa yolawulo olubi lobushushu okanye ungcoliseko.

I-Porosity: Ibangelwa ziigesi ezivaleleke kwi-weld pool, rhoqo ngenxa yokungonelanga kwerhasi yokukhusela.

I-Discoloration: Ukushisa ngokugqithiseleyo kunokubangela i-oxidation, okukhokelela kwindawo enombala we-rainbow.

Usetyenziso lwe-Stainless Steel Welding

Izixhobo zokuLungisa ukutya: Insimbi engenasici isetyenziswa ngokuqhelekileyo kwiitanki, imibhobho, kunye nomgangatho kwimveliso yokutya ngenxa yokumelana nokubola kunye nokulula kokucoca.

Izixhobo zoNyango kunye nezoNyango: Izixhobo zotyando, izinto ezifakelwayo, kunye nezikhongozeli ezingenazintsholongwane zifuna i-welds echanekileyo, ecocekileyo.

Umzi-mveliso we-Aerospace: Intsimbi engatyiwayo isetyenziswa kumalungu enqwelo-moya ngokomelela kwayo nokuxhathisa amaqondo obushushu aphezulu.

I-Architecture kunye noKwakha: I-Handrails, i-facades, kunye nezinye izinto zesakhiwo zisebenzisa i-stainless steel ukuqina kunye nobuhle.

Ishishini leeMoto: Iinkqubo zokukhupha umbhobho, iitanki zamafutha, kunye nezinxibo zokuhombisa zidla ngokwenziwa ngentsimbi engenasici.

Ukuqukumbela

I-Welding steel stainless yinzululwazi kunye nobugcisa, efuna ukuqonda iimpawu ezizodwa kunye nemingeni. Ngobuchule obufanelekileyo, ukulungiswa, kunye nezixhobo, unokufezekisa umgangatho ophezulu, i-welds ehlala ixesha elide egcina imathiriyeli's amandla kunye nokumelana nomhlwa.

Nokuba wenza amacandelo oshishino lokutya, ulwakha imbonakalo yoyilo, okanye usakha iindawo zemoto ezisebenza ngokuphezulu, ukuwelda kwentsimbi kunika indibaniselwano yobuhle, ukuqina, kunye nokusebenza. Ukulandela ezona ndlela zilungileyo kunye nokukhetha indlela efanelekileyo ye-welding kuya kuqinisekisa iziphumo eziyimpumelelo kwiiprojekthi zakho zentsimbi engenasici.

Ixesha lokuposa: Oct-15-2024