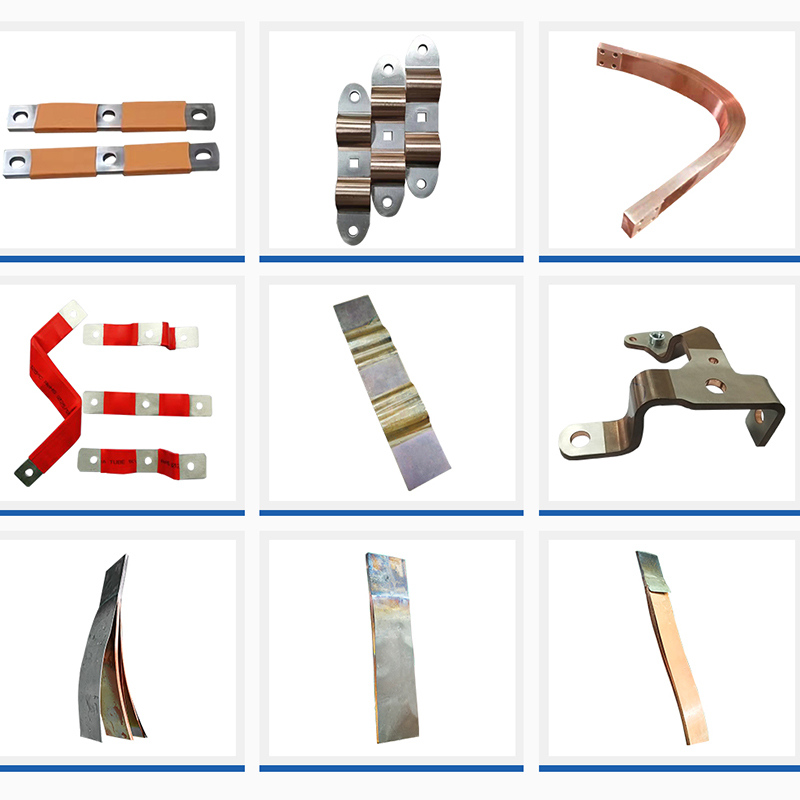

Iibhasizisetyenziswa kakhulu kwicandelo lamandla elitsha langoku, kubandakanywa amashishini afana nezithuthi zombane, ugcino lwamandla, kunye neenkqubo zombane. Njengoko iteknoloji ihambela phambili, izinto zeBusbar ziye zavela kwi-copper ukuya kwi-nickel yobhedu, i-aluminium yobhedu, i-aluminium, kunye ne-graphene composite. Ezi Busbars zithembele kakhulu ekubunjweni nasekudibaniseni, njengoko kufuneka zidibanise neebhetri, iinkqubo zokulawula umbane, kunye nezinye izinto. Ukuwelda kwiziphelo namacandelo aphakathi kubalulekile kwezi zidibaniso, ngeukusasaza iweldingibeyeyona ndlela iphambili yokwenza iBusbar.

Iintlobo zeBusbarDiffusion Welding Equipment

Kukho iintlobo ezimbini eziphambili zeBusbar diffusion welding equipment. Enye i-resistance diffusion welding, etshisa ngokuthe ngqo izinto ezisisiseko ngokusebenzisa umsinga ophezulu. Enye i-high-frequency diffusion welding, apho igraphite ifudunyezwa kwaye idlulisela ubushushu kwizinto ezisisiseko. Zombini iindlela zokutshisa izinto ezisisiseko kwiqondo lokushisa elithile kwaye, phantsi koxinzelelo oluphezulu, zenza uxhulumaniso lwesigaba esiqinileyo, ukufezekisa umphumo we-welding we-diffusion. Indlela yokufudumala esetyenziswayo ixhomekeke kwizinto zeBusbar.

I-Resistance Diffusion Welding

I-resistance diffusion welding isetyenziswa ikakhulu kwii-Busbars zobhedu, njengoko ubhedu lunendawo ephezulu yokunyibilika kunye nokuhanjiswa. Ukuqinisekisa ukufudumeza okufanayo kunye nokukhawulezisa inkqubo, i-electrode yegraphite isetyenziswa. I-electrode ephezulu kunye nesezantsi iqhuba i-high current kwi-copper Busbar, iyifudumeza ngokuxhatshazwa koqhagamshelwano phakathi kweengqimba ezininzi ze-foil yobhedu. Iielectrode zegraphite ngokwazo nazo zivelisa ubushushu ngenxa yokuxhathisa kwazo okuphezulu. Oku kufudumeza okudibeneyo kunokunyusa ubushushu be-Busbar yobhedu ukuya kwi-600 ° C, ukufikelela kwi-1300 ° C, okuvumela ukusasazwa ngempumelelo kwe-welding phantsi koxinzelelo oluphezulu.

Ukuwelda kwe-High-Frequency Diffusion

I-high-frequency diffusion welding ifanelekile kwi-aluminium Busbars, i-copper-nickel Busbars, i-copper-aluminium Busbars, kunye nee-composite Busbars ezifana ne-copper kunye ne-non-metal indibaniselwano. Le ndlela isebenzisa ukufudumala okungathanga ngqo, okwenza kube yinto efanelekileyo kwi-welding complex materials. Kwi-high-frequency diffusion welding, igraphite iyafudumeza ize idlulisele ubushushu kwizinto ezisisiseko, ngamaqondo obushushu afikelela kwi-1200°C. Ngaphantsi koxinzelelo oluphezulu, izinto zenza uxhulumaniso oluqinileyo.

I-Diffusion Welding yezinto ezahlukeneyo zeBusbar

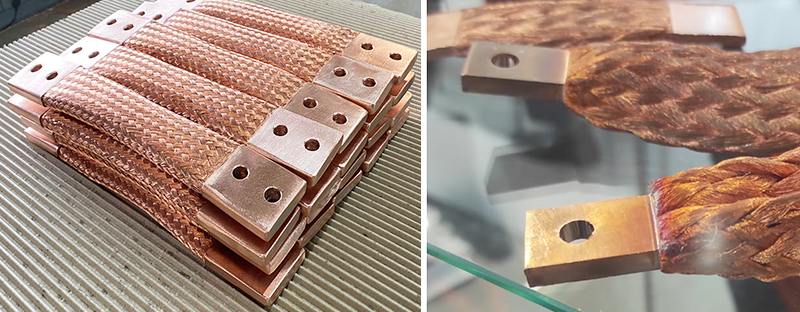

Izinto zobhedu zilula kakhulu ukuwelda ngenxa yokuzinza kweeoksidi zazo. Iibhasi ezishinyeneyo zobhedu, ezifana nezo zisetyenziswa kwiinkqubo zamandla, zifuna ukuxhathisa ukusasazwa kwe-welding ngenxa yokusebenza kwayo okuphezulu kokufudumeza. Ezi zinokutyeba njenge-50mm kunye nendawo ye-welding ye-200x200mm. Ii-Thinner Busbars, ezifana nezo zisetyenziswa kwizithuthi zombane, ubukhulu becala yi-3mm enendawo yokuwelda eyi-25x50mm, inokusebenzisa ukuxhathisa okanye i-high-frequency diffusion welding.

Iibhasi ze-aluminiyam zinzima kakhulu ngenxa yeqondo lokunyibilika kwe-aluminiyam (670°C) kunye nendawo yokunyibilika ephezulu kakhulu ye-aluminiyam oxide (2000°C). Kwi-aluminium, i-high-frequency diffusion welding idla ngokusetyenziswa, kunye nezinto ezicociweyo kwangaphambili ukuze kususwe i-oxides. Ubushushu bokusasazwa ngokuqhelekileyo bubekwe ngaphantsi kwe-600 ° C.

I-Copper-nickel Busbars iqulethwe ngamacandelo amaninzi e-foil yobhedu kunye ne-coating ye-nickel ye-foil yokugqoka kunye nokumelana nokubola. I-high-frequency diffusion welding idla ngokusetyenziswa ukuphatha umahluko omkhulu wokumelana nombane phakathi kobhedu kunye nenickel. Ii-Busbars ezihlanganisiweyo, ezifana nobhedu oludityaniswe negraphene, zifuna i-welding ye-high-frequency diffusion welding ukulawula ngokuchanekileyo inkqubo yokufudumeza kunye nokuphepha ukonakalisa izinto ezisisiseko ngelixa uzuza ukusasazwa.

Iindlela zoxinzelelo kwi-Busbar Diffusion WeldingUmatshini

I-welding ye-diffusion ifuna uxinzelelo oluphezulu, olunokuthi lusetyenziswe ngokusebenzisa i-boosters yolwelo lomoya, iinkqubo ze-hydraulic, okanye iinkqubo ze-servo. Iindlela eziqhelekileyo zisebenzisa iinkqubo ze-hydraulic kwimveliso yazo ezinzileyo kunye namandla aphezulu. Kule mihla, ukucinezelwa kwe-servo kuya kuthandwa ngakumbi kulawulo lwayo oluchanekileyo kunye nokufuduswa okuhlengahlengiswayo, kuqinisekisa ukuchaneka okuphezulu kwimilinganiselo yemveliso edityanisiweyo.

Ukuqukumbela

Lo ngumbono omfutshane weBusbar diffusion welding. Ukuba ujonge indlela efanelekileyo ye-welding yeeBusbars, eli nqaku kufuneka linike iimpendulo. Ngophuhliso oluqhubekayo lwetekhnoloji ye-welding, iindlela ezintsha zobuchule ziyamkelwa ukuhlangabezana neemfuno zoluntu lwanamhlanje.

Ixesha lokuposa: Sep-20-2024