Ukudityaniswa okungaphelelanga, eyaziwa ngokuba yi "cold weld" okanye "ukungabikho kokudibanisa," ngumba obalulekileyo onokuthi wenzeke ngexesha leenkqubo ze-welding usebenzisaoomatshini bokuwelda amabala. Ibhekisela kwimeko apho isinyithi esityhidiweyo sihluleka ukuxutywa ngokupheleleyo kunye nezinto ezisisiseko, okubangela ukudibanisa okubuthakathaka kunye nokungathembekiyo. Eli nqaku lijolise ekuphononongeni izinto ezahlukeneyo ezinokukhokelela ekudibaneni okungaphelelangaukuwelda indawo.

Welding Yangoku

I-Welding yangoku yenye yezona zinto zibalulekileyo kwiparameters kwiinkqubo welding, kwaye inomphumela wokuphindaphinda kubushushu obuveliswa ngexesha le-welding. I-welding current eyaneleyo yenye yezizathu eziphambili zokungaxutywanga. Xa i-welding current iphantsi kakhulu, ayinakuvelisa ubushushu obaneleyo ukunyibilikisa ngokupheleleyo i-substrate. Ngenxa yoko, isinyithi esityhidiweyo asikwazi ukungena kwaye sidibanise ngokufanelekileyo, okubangela ukudibanisa okungaphelelanga kwi-welding interface.

Uxinzelelo lwe-Electrode olunganelanga

Ukungonelanga kwamandla ombane nako kunokukhokelela ekudibaneni okungaphelelanga. Uxinzelelo lombane lusetyenziswa kwi-workpiece ukuqinisekisa uqhagamshelwano oluchanekileyo kunye nokungena ngexesha le-welding. Ukuba amandla ombane aphantsi kakhulu, indawo yoqhagamshelwano phakathi kwe-workpiece kunye ne-workpiece encinci, xa i-welding, intshukumo ye-athomu ye-solder joint ayinakwanela, ukwenzela ukuba i-solder joint joints ayifanelekanga ngokupheleleyo.

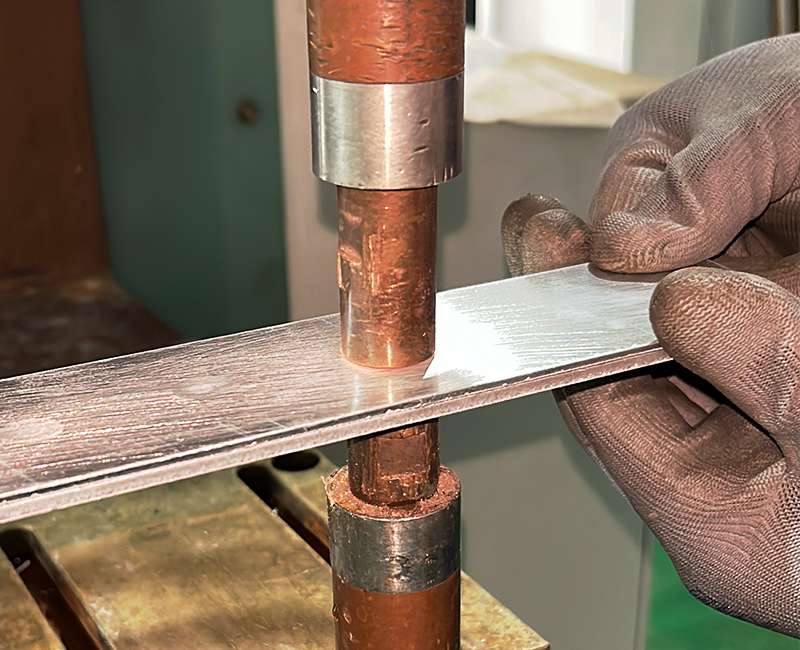

Ulungelelwaniso lwe-Electrode aluchanekanga

Ukulungelelaniswa okungalunganga kwee-electrodes kunokukhokelela ekusasazweni kobushushu obungalinganiyo, okubangela ukudibanisa okungaphelelanga. Xa i-electrodes ingahambelani, ubushushu obuveliswayo ngexesha lenkqubo ye-welding ayinakusasazwa ngokulinganayo kuyo yonke indawo ye-welding. Oku kuhanjiswa kobushushu obungalinganiyo kunokukhokelela ekudibaneni okungaphelelanga kwiindawo zendawo. Ngoko ke, ngaphambi kokuba umsebenzi we-welding uqale, qiniseka ukuba ukhangele ukuba i-electrodes ephezulu nangaphantsi ichanekile, ukuba ayihambelani, kuyimfuneko ukulungelelanisa ngokusebenzisa isixhobo.

I-Workpiece Surface Ungcoliseko okanye i-Oxidation

Ungcoliseko okanye i-oxidation yendawo yokusebenza inokuphazamisa ukudityaniswa okuqhelekileyo ngexesha le-welding yendawo. Ukungcola, okufana neoli, ukungcola, okanye iingubo, zisebenza njengomqobo phakathi kwentsimbi etyhidiweyo kunye ne-substrate, inhibiting melting. Ngokufanayo, i-oxidation yomhlaba inokwenza umaleko we-oxide okhusela ukudibanisa okufanelekileyo kunye nokudibanisa. Umzekelo, xa ufuna ukuwelda i-fin eyenziwe nguisipheloityhubhuumatshinikwi-tube, ukuba umphezulu we-tube unomhlwa, i-welding kufuneka ingabi yi-fusion, ukwenzela ukuba i-welded joint iya kungazinzi kwaye ichaphazele umgangatho wemveliso.

Ixesha elifutshane leWelding

Ixesha le-welding elaneleyo livimbela isinyithi esityhidiweyo ukuba sihambe ngokwaneleyo kwaye sidibanise nezinto ezisisiseko. Ukuba ixesha le-welding lifutshane kakhulu, i-metal contact ayixutywanga ngokupheleleyo ngaphambi kokuphela kokukhutshwa, kwaye oku kudibanisa okungonelanga kuya kukhokelela kwi-welding ebuthakathaka kwaye engathembekanga.

Ukuqonda izinto ezikhokelela ekudibaneni kwe-welding engaphelelanga kubalulekile ekuqinisekiseni i-welds ekumgangatho ophezulu. Ngokucombulula iingxaki zokungonelanga kwe-welding okwangoku, ukungonelanga kwamandla ombane, ukulungelelaniswa kwe-electrode engafanelekanga, ukungcoliseka komhlaba okanye i-oxidation, kunye nexesha elaneleyo le-welding, unokunciphisa ukwenzeka kokudibanisa okungaphelelanga xa umsebenzi we-welding, ukwenzela ukuba umgangatho we-welding uphuculwe kakhulu.

Ixesha lokuposa: Sep-24-2024