I-aluminium isetyenziswe kwiinkalo ezahlukeneyo ngenxa yobunzima bayo, ukuxhathisa ukubola, ukuqhutyelwa kombane okulungileyo kunye nezinye iimpawu, kunye nokunyuka kwamandla amatsha, ukusetyenziswa kwe-aluminium kuye kwaqiniswa, kunye nokudibanisa kwe-aluminium ngaphezu kwe-riveting, i-bonding is ukuwelda, ukudibanisa ipleyiti aluminiyamukumelana weldingyinkqubo ebalulekileyo, iimeko zesicelo ngaphezu kwezicelo eziqhelekileyo zoshishino, Isetyenziswa ngokubanzi kwizithuthi zamandla amatsha, i-aerospace kunye nezinye iindawo.

Imigaqo yeAaluminiyamWelding

Iinzuzo zokuxhathisa i-aluminium plateukuwelda indawozicacile, ngaphandle kokongeza izinto ezincedisayo, kuphela ngesiseko sokunyibilika kwesinyithi kunokwenza i-solder eqinile.Aluminiyamemoyeni ihlala inomaleko wefilimu ye-oxide, indawo yokunyibilika kwe-aluminiyam yi-660 degrees Celsius, kwaye ifilimu ye-oxide yi-aluminium oxide, indawo yayo yokunyibilika imalunga ne-2000 degrees, kwaye inyibilika isiseko sezinto ukwenza undoqo kuqala ukuphula umaleko we-oxide. , ekwayinkqubo yokuwelda indawo ye-aluminium ithathwa njengesizathu esinzima ngakumbi.

UkuweldaEizixhoboSunyulo

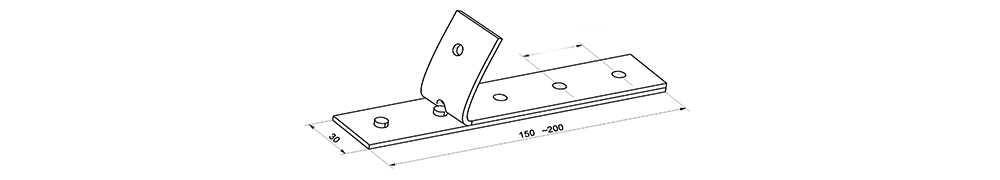

Ukukhethwa kwepleyiti ye-aluminiumumatshini wokuwelda indawo, i-intermediate frequency inverter ye-DC unikezelo lwamandla ngenxa yemveliso yangoku yi-DC, kunye nempumelelo ephezulu ye-thermal, ngoko lukhetho lokuqala lwe-aluminium plate spot welding. Ubonelelo lwamandla ombane akwinqanaba lesibini lesibini sisilungisi sesiqingatha samaza, unikezelo lwamandla ogcino lwamandla nangona imveliso iyiDC kodwa ixesha lifutshane kakhulu, ngoko ke ukusebenza kwayo okubanzi akulunganga njengesixhobo se-DC spot welder esiphakathi. unikezelo lwamandla lunezicelo kwisigaba sokuqala, imeko yesicelo sexesha elizayo iya kuba ngaphantsi nangaphantsi.

AmanqakuTo NoteWinkukhuAaluminiyamSimbizaWelding

Aluminiyam ipleyiti indawo ukuwelda inkqubo, ipleyiti aluminiyam conductivity kunye thermal conductivity ratio iphezulu, ngoko ke imfuneko enkulu yangoku kunye nexesha ukuwelda efanelekileyo, nto leyo efuna ingqalelo kula manqaku alandelayo:

1. Amandla ezixhobo kufuneka abe mkhulu ngokwaneleyo ukuze kuqinisekiswe ukuba imveliso yangoku inokuba yinto ephezulu ngexesha elifutshane, ngokuqhelekileyo amaxesha angama-2-3 ngoku ye-carbon steel spot welding;

2. I-electrode idinga ukupholisa kwamanzi okunamandla, kwaye ubushushu bunokuthatyathwa ngokukhawuleza emva kwe-welding;

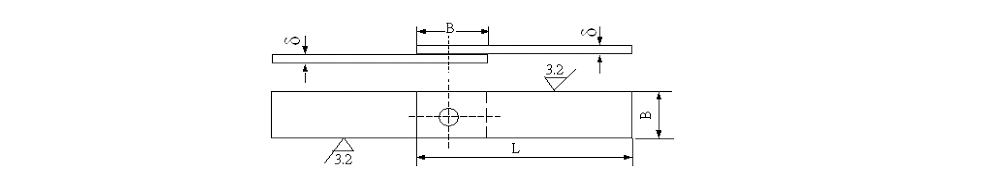

3. I-diameter ye-spherical yesiphelo sangaphambili se-electrode kufuneka ihambelane, kwaye i-plate ehlukeneyo idibanisa kufuneka ibe neendawo ezahlukeneyo, kwaye umgaqo akufanele ube ngaphantsi kwe-SR25;

4. I-diameter ye-electrode kufuneka ihambelane nobukhulu bepleyiti, kwaye i-electrode diameter engaphantsi kwe-1.0MM yepleyiti yi-13; Ubukhulu beshiti 1.0-1.5 Idayamitha ye-Electrode yi ¢16; Ubukhulu beshiti 1.5-2.0 Idayamitha ye-Electrode yi ¢20; Ubukhulu bepleyiti ngaphezu kwe-2.0 ye-electrode ubukhulu abukho ngaphantsi kwe-¢25;

5. Izinto ze-electrode zenziweingxubevange yobhedukunye ne-conductivity ephezulu okanye ubhedu obunzima, kunye ne-conductivity ayikho ngaphantsi kwe-80% IACS;

6. Ukuhlangabezana nomgangatho ophezulu we-solder joints, umphezulu we-aluminium plate kufuneka ube yi-deoxidized, pickling okanye i-polish, kunye nokumelana nomgangatho we-A-level joint ye-aviation / imveliso yezempi kufuneka ilawulwe kwi-50 microohm-100 microohm;

UkuweldaQimekoIukuhlolwa

I-Aluminiyam ipleyiti yendawo yokuwelda emva kovavanyo ikakhulu uvavanyo olungonakalisi kunye nokufunyanwa komonakalo amacandelo amabini, angonakalisi ikakhulu ngokubonwa, i-X-reyi kunye nobhaqo lwe-ultrasonic, ukubhaqwa komonakalo ubukhulu becala ukolula, amaxesha aphantsi kunye nokunye ukubhaqwa, iindlela ezithile zokufumanisa zezi zilandelayo. :

1. Ukuhlolwa kwembonakalo, kubandakanywa imilo yejoyinti ye-solder, umbala we-solder joint, ubunzulu be-indentation, njl.;

2. Ukufunyanwa kwe-X-ray, ukubonwa kwefilimu yobubanzi be-weld core, nokuba i-weld core cracks, i-shrinkage kunye nezinye iziphene;

3. Ukufumanisa amandla aphantsi, amaxesha angama-15-25 emva kokubola kweqhekeza lamalungu e-solder, ukufumanisa ukugqithiswa kwe-welding, iziphene ze-welding, njl.;

4. Uvavanyo lwe-tensile, olona vavanyo luphambili lwamandla e-solder;

5. Uvavanyo lokuhluba, uvavanyo lokuqhawula okanye ukukrazula kwamalungu e-solder, ikakhulu esetyenziselwa ukufumanisa amandla kwisayithi kunye nokuqinisekiswa kobubanzi obungundoqo.

6. Ukuxilongwa kwe-Ultrasonic, kunye nokuphuculwa kweteknoloji yokufumanisa i-ultrasonic, ukusetyenziswa kwe-spot welding discovery iyaqhubeka isomeleza, ngokuthelekisa i-wave wave ebonakalisiweyo, kunye nokuvuthwa kwe-teknoloji ye-imaging ye-digital, ukufunyanwa kwe-polycrystalline intloko ye-ultrasonic iya kuba yinto efanelekileyo yokukhetha. uvavanyo olungonakalisi lwe-aluminiyam spot welding.

Isishwankathelo

Ngokusetyenziswa okuqolileyo kweMFDC umatshini welding, kunye nokuphuculwa kwenkqubo yokuwelda kunye neendlela zokubona, umgubasi we-aluminiyam ipleyiti yebala ukuwelda iya kuba ngaphantsi nangaphantsi, kwaye iya kukhuthaza ukuwelda kwendawo ye-aluminium kwi-industrial lightweight, kunye namandla amatsha, i-aerospace kunye nangaphezulu. esetyenzisiweyo.

Ixesha lokuposa: Aug-07-2024