I-Metal sheet welding yinxalenye ebalulekileyo yenkqubo yemveliso yeemveliso ezahlukeneyo zetsimbi. I-Spot welding isetyenziswa kakhulu kwishishini lokwenziwa kweemoto, kwishishini lezixhobo zombane zasekhaya, kunye neshishini lebhokisi yentsimbi. Itekhnoloji yale mihla ifuna umgangatho ophezulu wokuwelda. Kweli nqaku, siza kuchaza inkqubo ye-welding ngokubanzi kwaye sixoxe ngeenzuzo zeukuwelda indawokushishino lweemoto.

Yintoni iSpot Welding

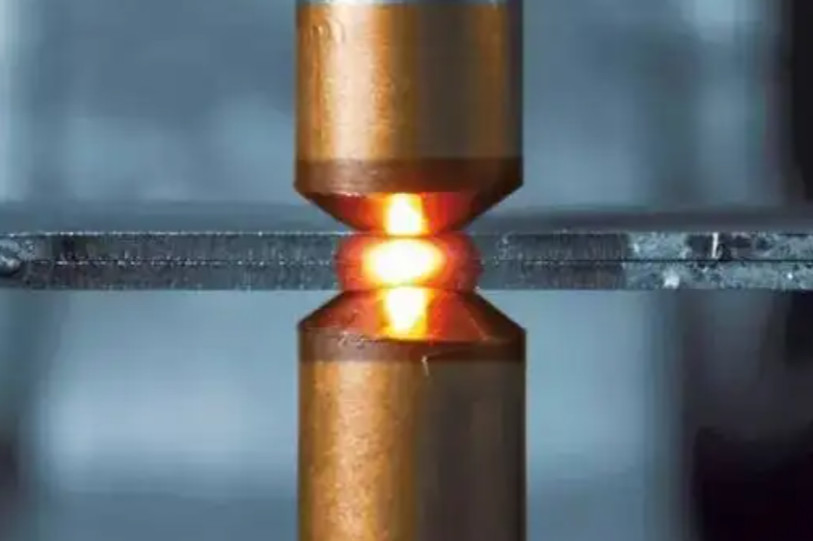

Spot welding luhlobo lweukumelana welding. Kubandakanya ukubeka ii-workpieces ezimbini phakathi kwee-electrode eziphezulu kunye nezisezantsi, ukuzifudumeza ngomsinga wombane, kunye nokufaka uxinzelelo lokudala i-plastic state kwindawo yokudibanisa yezinto zokusebenza, ezivumela ukuba zidibanise. Umgaqo wayo ulula: ngokuqhuba umbane ngee-electrode ezimbini zobhedu, ukuchasana kwandisa ubushushu bezinto zokusebenza, kubangele ukuba bancibilike kwaye badibanise. Yiyo loo nto ikwabizwa ngokuba yi-resistance welding. Xa kuthelekiswa nezinyeiinkqubo welding, i-spot welding ayifuni ukongeza izinto ze-welding, kwaye ukusebenza kulula.

Indlela yokubona iWeld?

1: Umsebenzi wokucoca uMphezulu

Spot Welding Ngokuqhelekileyo Materials

Aluminiyam: I-Aluminiyam ixhaphake kakhulu kwi-welding yendawo, ngakumbi kwishishini leemoto, apho iimpawu zayo ezikhaphukhaphu zinokuthatha indawo yezakhiwo eziqinileyo. Nangona kunjalo, i-aluminiyam ye-welding inzima kakhulu ngenxa ye-conductivity ephezulu, ifuna malunga nokuphindwe kabini okwangoku kwezinto eziqhelekileyo. Ke ngoko, xa udibanisa i-aluminium, kufuneka ukhethe izixhobo ezinamandla aphezulu.

Intsimbi: Intsimbi yeyona nto ixhaphakileyo kwiwelding yendawo. Yimpahla enzima, kwaye izinto ezininzi zeemoto zisebenzisa intsimbi. I-Spot welding isetyenziselwa ukuwelda imizimba yemoto kunye nezinto eziqinileyo ze nut.

Ubhedu: Spot welding ubhedu kufuna ubuchule obukhethekileyo. I-Copper ine-conductivity ephezulu ye-thermal kunye nombane, okwenza kube lula ukunamathela kwi-electrodes. Ngoko ke, sikhetha i-tungsten okanye i-molybdenum electrodes. Ngexesha le-welding, i-brazing material kufuneka yongezwe phakathi kwezinto ezimbini zokusebenza, ngoko ke ubhedu lusetyenziswa ngokuqhelekileyo.

Intsimbi yegalvanized: I-Welding intsimbi ye-galvanized inzima ngakumbi kunentsimbi ye-welding, efuna i-current ephezulu. Indawo yokuncibilika kwengubo ye-galvanized iphantsi kuneyentsimbi, ngoko kulula ukugqithisa kunye nokwenza i-splashes ngexesha le-welding.

Umsebenzi wokucoca uMphezulu woMphezulu

Phambi kwewelding, kubalulekile ukujonga ukuba i-workpieces inomhlwa okanye i-oxidation. Ukuba benjenjalo, ii-workpieces kufuneka zinyangwe. Ungasebenzisa i-sandpaper okanye i-grinder ukwenza umphezulu ube mpuluswa. Ngaphandle koko, kuya kubakho i-splatter eninzi, enokuchaphazela umgangatho we-welding.

2: Ukuthathela ingqalelo izinto ezi-4 eziguquguqukayo phambi kwe-Welding kunye nokuSeta iiparamitha

Uxinzelelo

Ukukhetha uxinzelelo olufanelekileyo kubalulekile. Ukuba uxinzelelo lwe-electrode luphezulu kakhulu okanye luphantsi kakhulu, lunokunciphisa amandla e-weld kwaye lwandise ukusasazeka kwayo. Xa i-welding, kubalulekile ukuqwalasela iimpawu ze-workpiece xa ubeka uxinzelelo.

Ixesha le-Welding

Ukumisela ixesha elifanelekileyo le-welding kubalulekile. Ukuba ixesha le-welding lifutshane kakhulu, i-workpiece ayinakunyibilika ngokwaneleyo ukuhlangabezana neemfuno ze-welding. Kwelinye icala, ukuba ixesha lokuwelda lide kakhulu, i-workpiece ithambekele kwi-deformation, ekhokelela kumanqaku amakhulu e-weld.

I-Welding yangoku

I-welding yangoku kunye nexesha ziyancedisana, kodwa nazo zinemida yazo. Ukufumana ibhalansi elungileyo phakathi kwezi zibini ngundoqo ekuveliseni i-welds egqibeleleyo.

3: Spot Welding Machine

Isixhobo esifunekayo ukuwelda indawo aumatshini wokuwelda indawo, eza kwiimodeli ezahlukeneyo. Ukukhetha umatshini we-welding efanelekileyo kuxhomekeke kwiimpawu ze-workpiece kunye neemfuno ze-welding. Umzekelo, ukuba ufuna ukuwelda kunye iipleyiti ezimbini zentsimbi estainless 2mm ukufezekisa amandla afunekayo omzali, kuya kufuneka ukhethe umatshini wokuwelda onamandla aphezulu. Umatshini wokuwelda indawo osemgangathweni kunye ne-130KVA unokufeza oku. Nangona kunjalo, ukuba ufuna ukuwelda iipleyiti ze-aluminiyam eziyi-2mm, uya kufuna umatshini we-welding oqhelekileyo one-260KVA.

4: Beka i-Workpiece phakathi kwe-Electrodes kwaye uqalise i-Welding

Nje ukuba ukhethe umatshini wokuwelda ofanelekileyo, lixesha lokuba uqale ukuwelda. Emva kokudibanisa ukunikezelwa kwamandla kunye nokulungelelanisa iiparitha, faka i-workpiece elungiselelwe phakathi kwezi zibinii-electrode cap. Cinezela iqhosha le-pedal yeenyawo, kwaye i-electrode iya kucinezela phantsi, ifudumeza kwaye icinezele i-workpieces, ngaloo ndlela idibanisa iindawo zokudibanisa ezimbini zokusebenza kunye.

I-5: Uvavanyo lwe-Peel Emva kwe-Welding

Emva kokutshisa i-workpiece, kunzima ukuvavanya amandla e-weld ngeso lenyama lodwa. Kulapho kufuneka usebenzise izixhobo zokuvavanya amandla e-weld. Ukuvavanya i-Peel yindlela enkulu. Ngexesha lovavanyo lwe-peel, jonga amandla aphezulu afikelelekayo xa uxobula i-workpiece. Ezinye ii-workpieces zineemfuno ezithile zolu xabiso ukuze kubonwe ukuba i-weld yamkelekile.

IiNzuzo zeSpot Welding For Automotive Industry

Izihlanganisi eziqinileyo nezihlala ixesha elide

Iindawo ezidityanisiweyo zisebenzisa i-welding yokumelana zenza amalungu aqinileyo kwaye ahlala ixesha elide. Iimveliso ezenziwe ngolu hlobo zomelele kwaye zizinzile, nto leyo ibalulekileyo kushishino lweemoto. Ngokomzekelo, ukuba indongomane ayidityaniswanga kakuhle, inokukhokelela kwiingozi endleleni. Ukuchaneka kunye nokuthembeka kubaluleke kakhulu kwicandelo leemoto, apho neyona mpazamo encinci ingamkelekanga. Ke ngoko, i-resistance welding idlala indima ebalulekileyo ekuqinisekiseni ukuba le migangatho iyafezekiswa.

Ukufana kwiZidibaniselwano

Kumacandelo ewelding yeemoto, akubalulekanga nje ukuba iiwelds zomelele kodwa nakwiimveliso ezidityanisiweyo zikhangeleke zithandeka. I-resistance welding inokufezekisa le mfuneko. Ngokukodwa ukuwelda umzimba wemoto, yonke indawo ye-weld kufuneka ingabonakali, njengoko ichaphazela ukusetyenzwa okulandelayo kunye nenkangeleko iyonke yesithuthi.

Ukudityaniswa kweMathiriyeli eFanayo

I-Resistance welding ikwafanelekile ukuwelda izinto ezahlukeneyo. Kwishishini leemoto, kukho amacandelo apho izinyithi ezahlukeneyo kufuneka zidityaniswe kunye. Kulapho i-welding yokumelana nayo iza luncedo, njengoko inokudibanisa izinto ezahlukeneyo, njengentsimbi kunye ne-aluminium.

Isantya seWelding

Ukumelana ne-welding ayifuni ucingo lokuzalisa. Iyakhawuleza ukuwelda iindawo ezincinci. Kwishishini leemoto, apho uninzi lwamacandelo amancinci adityanisiwe, inkqubo iyakhawuleza kwaye izenzekelayo ngokulula, igcina abasebenzi kunye nokunyusa ukusebenza kakuhle kwe-welding.

Ukuphindaphinda

Ngenxa yokufaneleka kwayo kwi-welding imveliso ephindaphindiweyo, i-welding yokumelana inokufuna iparameter kunye nohlengahlengiso lwezixhobo xa utshintshela kwiinkcukacha ezahlukeneyo. Ke ngoko, ilungele ngakumbi ukuwelda iimveliso ezinomthamo ophezulu. Amacandelo eemoto, ngokuchanekileyo ngenxa yolu phawu, afumana i-welding echasayo ilungele ishishini leemoto.

I-resistance welding isetyenziswa ngokubanzi kumacandelo amashishini anamhlanje. Itekhnoloji yayo ihlaziywa ngokuqhubekayo ukuze ihambelane nophuhliso lwamashishini, isiya kwi-automation. Ukuze ufunde ngakumbi malunga nokumelana ne-welding, nceda ulandele uhlaziyo lwethu.

FAQ:

1,Yeyiphi indlela yokuwelda ekufuneka ndiyisebenzise ukuwelda idrum yeoli yentsimbi engenasici ekufuneka ivalwe ngokuqinileyo?

Kwiimfuno zomoya, ungasebenzisa i-welding ye-seam, aumthungo welderndingayenza.

2,Loluphi uhlobo lomatshini wokuwelda olusetyenziswa ngokubanzi kumalungu omzimba wemoto?

Imizimba yemoto idla ngokusetyenziswaindawoumpu welding, ezibhetyebhetye kwaye kulula ukuzenzela.

3,Yeyiphi indawo yokuwelda amandla efunekayo ukuwelda intsimbi eshinyeneyo eyi-2mm?

Indawo ye-130kVA yeldumatshini wokucocaizakusebenza kakuhle.

4,Ndiyiwelda njani i-M8 nut kwi-2mm carbon steel plate?

Ungasebenzisa i-weld yokubonisaumatshini wokucoca.

5,Ndizilungisa njani iiparamitha zeendawo zokuwelda?

Lungisa iiparamitha ngokusekwe kwiinkcukacha zomsebenzi wakho kunye neemfuno ze-welding.

6,Njanitoweld indawo ngaphandle kwe welder?

Ungasebenzisa irobhothi ukulayisha ngokuzenzekelayo kunye ne-welding.

7,Njanitoweld aluminiyam?

I-Aluminiyam inendawo ephantsi yokunyibilika, ngoko ufuna amandla aphezulu. AIMFDCIsixhobo sokuwelda sinokusetyenziswa.

Ixesha lokuposa: May-30-2024