1.Intshayelelo

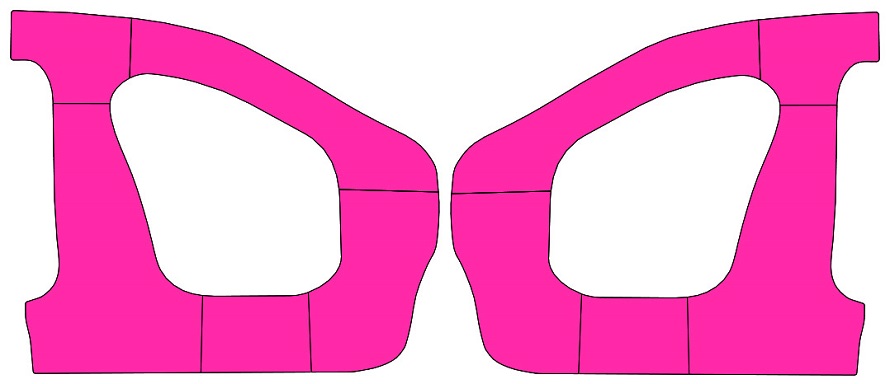

Amakhonkco omnyango omnye athandwa kakhulu kwiinkampani zemoto eziqhelekileyo ngenxa yoqoqosho kunye nokhuseleko lwabo.Ngenxa yamandla ahlukeneyo kunye neemfuno zolwakhiwo lwamacandelo ahlukeneyo, ubukhulu obuhlukeneyo kufuneka bufezekiswe kwiindawo ezahlukeneyo, ezibizwa ngokuba ngamashiti okuqinisa okanye iipleyiti zepatch, ngoko ke kufuneka zibe seMveni kokuthunga intsimbi yokunkqonkqoza kocango naphambi kwe-thermoforming, ukuwelda kwangaphambili. iyadingeka kunye nepleyiti yesiqwenga (isetyenziswa ikakhulu kwi-AB pillar reinforcement plate).

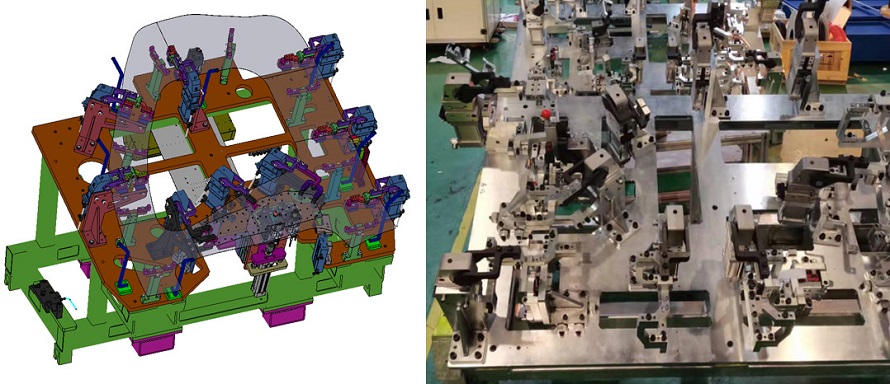

Uhlalutyo lwenkqubo:

I-2.Isiseko sezinto ezisisiseko sentsimbi enye phambi kwe-thermoforming yintsimbi ye-boron, amandla emveliso yi-280-400Mpa, kunye nokusebenza kwe-welding kulungile.Ukuqwalasela ukuba imilo yempahla yentsimbi yomnyango inkulu kunoko emva kokwenza, kwaye kukho iindawo ezininzi ze-solder kwi-patch board, idla ngokusetyenziswa indlela yokutya okuzenzekelayo, i-welding yendawo ezenzekelayo emva kokuhlanganisana.

3. Ityala:

Ucango knocker ye iprojekthi yemoto umzi-mveliso M, izinto 22MnB5, ubukhulu 1.6MM, iibhodi patch ezimbini, iyonke 78 amalungu solder, wasifumana ngokusebenzisa intshayelelo yomhlobo, sisebenzisa irobhothi ukulayisha oluzenzekelayo, irobhothi welding itotshi ukuwelda indawo ukuwelda, ukulayisha ngokuzenzekelayo.

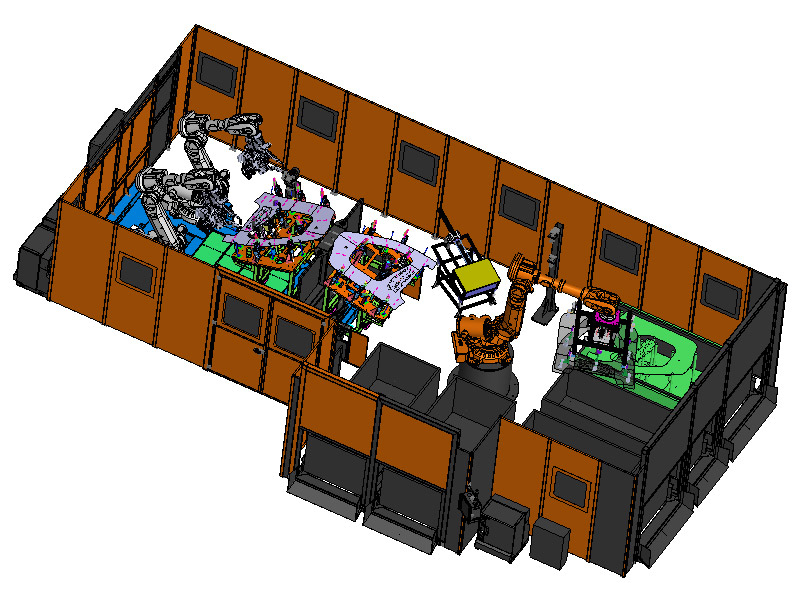

3.1 Uyilo lweskimu:

3.2 Intshayelelo yeProjekthi

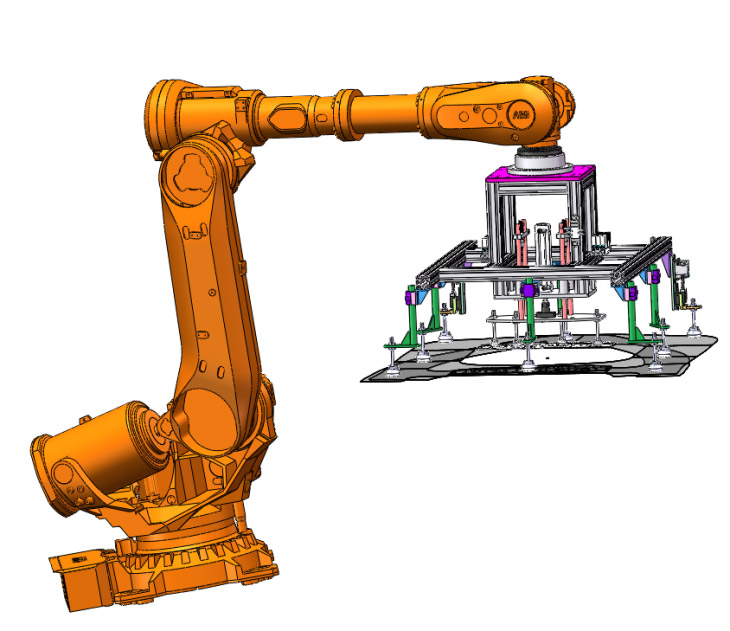

Izinto ezingenayo zikwimo yelori yezinto, ethintela ngokusisiseko ubume besixhobo sokusebenza, kwaye emva koko ibambe ngekomityi yokufunxa irobhothi kwaye ilungelelanise indawo, kwaye iyithuthe kwisixhobo se-turntable, kwaye emva kokuyibamba, iphawulwe ngezibane zokuwelda ezimbini ze-Anjia (ngenxa yenani elikhulu lamalungu e-solder, imipu ephindwe kabini isetyenziselwa ukubonwa) ), emva kwe-spot welding, i-robot ikhupha izinto kwilori yokutya.

a.Isikhululo sokubamba: i-workpiece ifunxwa kwilori yezinto eziphathekayo ngekomityi yokufunxa i-vacuum, kwaye emva koko idluliselwe kwisixhobo emva kokufikelela kwi-turntable;

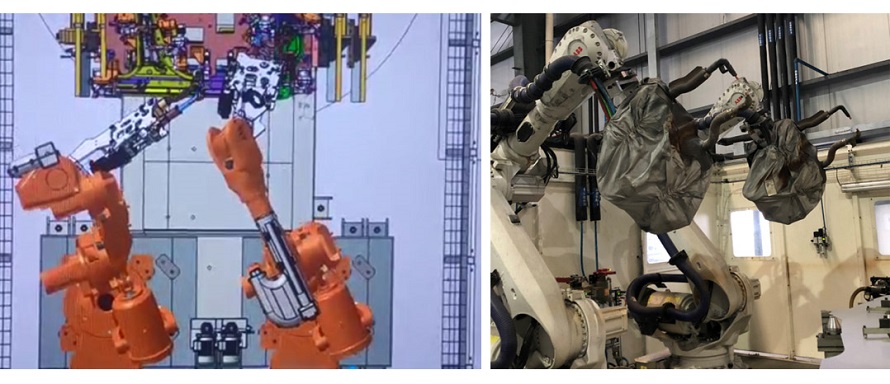

b.Isikhululo semipu yokuwelda kabini: imipu emibini yokuwelda iirobhothi ziye zalingisa kwaye zadityaniswa ngokuhambelanayo ngokweyona ndlela ilungileyo;

b.Isixhobo sokujikeleza: Ngenxa yobume obukhulu bomsebenzi, isixhobo esithambekileyo sisetyenziselwa ukunciphisa unyawo kunye nokunciphisa i-stroke efikelelekayo yerobhothi;

b.Ukuhlola kunye nokuqinisekiswa: Ububanzi be-weld nugget ekuhlolweni kwe-post-weld kudlula i-Ø6, kwaye umjikelezo we-welding ulawulwa ngaphakathi kweemfuno.

c.Isiphelo:

Indawo izinto ukuwelda of integrally ebunjwe enkqonkqoza emnyango kulula ukuyiqonda ngenxa imathiriyeli tyaba kunye namabala amaninzi welding, nto leyo inzima kakhulu ngaphantsi kwe ukuwelda indawo oluzenzekelayo emva kokwenza, kunye nenkqubo welding indawo yamkelwe kwakhona ngokwemveli ngokwentelekiso.Umahluko kuphela kukuba imilo yemveliso inkulu, eneemfuno ezithile zoyilo lonke lwendawo yokusebenza;kwixesha elizayo, ngakumbi nangakumbi izicelo ezidityanisiweyo yokunkqonkqoza emnyango, ukusetyenziswa gantry-uhlobo oluzenzekelayo indawo welding sheet kuya kuba ukhetho elungileyo.

Ithegi: Ukuqaliswa kweNkqubo yokuWelding ye-Automatic Spot Welding Workstation ye-Automobile Door Knob Sheet-Suzhou Agera Automation Equipment Co.,Ltd.

Inkcazo: Indawo yokusebenzela ye-welding ezenzekelayo yokunkqonkqoza kucango lwemoto isekelwe kwizinto ezifana nezixhobo ezisicaba, ii-solder joints, kunye neenkqonkqozi zocango ezinkulu nezinzima.ukuwelda.

Amagama aphambili: indawo yokusebenzela ye-welding ezenzekelayo yocango lwemoto olungenanto, inkqubo yerobhothi yokuwelda yeringi yocango lwemoto, inkqubo yokuwelda

Ixesha lokuposa: Feb-16-2023