Sheet Metal welding isetyenziswa kumashishini amaninzi. Nanini na xa ufuna ukujoyina iindawo zentsimbi, uya kuqwalasela indlela yokuyiwelda. Itekhnoloji ye-welding ihambele phambili kakhulu, kwaye ukukhetha indlela efanelekileyo yokuwelda kunokwenza umsebenzi wakho ube lula kwaye usebenze ngakumbi. Eli nqaku liza kukukhokela ekuqondeni i-welding sheet yentsimbi kwaye ikuncede ufumane indlela ye-welding efanelekileyo.

Yintoni Sheet Metal Welding?

Iphepha metal weldingitekhnoloji yokulungisa izinto, ebhekisa kuqhagamshelo lweMbiniokanye amacandelo amaninzi ahlukeneyo esinyithi abe yinye ngendlela ethile. Ngophuhliso lobuchwephesha boshishino, itekhnoloji ye-welding isetyenziswa ngokubanzi kwaye iyinkqubo ebalulekileyo ekusetyenzweni kwesinyithi kwishishini lokuvelisa.

Ziziphi iindlela zokuwelda ngentsimbi?

Kukho iintlobo ezininzi zeendlela zokuwelda isinyithi, ngokwesimo kunye neempawu zenkqubo yesinyithi kwinkqubo ye-welding, iindlela ze-welding zetsimbi zahlulwe kakhulu zibe ziindidi ezintathu: ukuwelda kwe-fusion, i-welding yoxinzelelo kunye ne-brazing.

Fusion Welding

I-Fusion welding yindlela yokudibanisa iinxalenye zetsimbi ngokufudumeza kunye nokunyibilika kunye. Le ndlela ayifuni uxinzelelo. Ujongano lwemisebenzi emibini lufudunyezwa, lubangela ukuba isinyithi sivelise amandla amakhulu e-athomu, senza imeko yolwelo kwindawo eshushu. Iiathom zesinyithi zezixhobo zokusebenza ezimbini zisasazeka ngokupheleleyo kwaye zidibanise. Xa intsimbi etyhidiweyo iphola, yenza idibano eqinileyo edityanisiweyo.

Ubuchwephesha bokuwelda obuqhelekileyo bubandakanya i-arc welding, i-gas welding, kunye ne-laser welding.

Arc Welding

Ukuwelda kweArcinikwe amandla ngumthombo wombane okhupha phakathi kwe-electrode kunye nezixhobo zokusebenza ezimbini ukwenza i-arc. Le arc iguqulela kubushushu, inyibilika i-electrode kunye nezixhobo zokusebenza, ukudibanisa isinyithi kunye. Ngexesha lenkqubo ye-welding, i-voltage ephantsi kunye nephezulu yangoku ivelisa amaqondo obushushu aphezulu kunye nokukhanya okukhulu, ukutshisa i-electrode kunye nezinto zokusebenza ukwenza i-pool etyhidiweyo epholileyo ukwenza i-weld.

Le ndlela yokuwelda inoluhlu olubanzi lwezicelo kwaye ingasetyenziselwa ukuwelda iintsimbi ezahlukeneyo ezifana nentsimbi engatyiwa, ialuminiyam, ubhedu, kunye nentsimbi yekhabhoni ephezulu. Ngenxa yokuba izixhobo zokuwelda i-arc ziphathwa kwaye kulula ukuzisebenzisa, zisetyenziswa kakhulu kumashishini afana nokwenziwa koomatshini, ukwakhiwa, kunye nokwakhiwa kweenqanawa. Umzekelo, isetyenziselwa ukudityaniswa kwe-rebar kulwakhiwo. Ukongeza, i-arc welding isetyenziswa rhoqo ekulungiseni izixhobo kunye nokulungiswa kwendlela kaloliwe.

I-arc welding ifuna umatshini wokuwelda we-arc, iinduku zokuwelda, kunye nekhaka lobuso. Yindlela ye-welding ephantsi kwaye isetyenziswa ngokubanzi. Nangona kunjalo, ngenxa yobunzima bayo bezobugcisa, umgangatho we-weld ubukhulu becala uxhomekeke kwinqanaba lezakhono ze-welder.

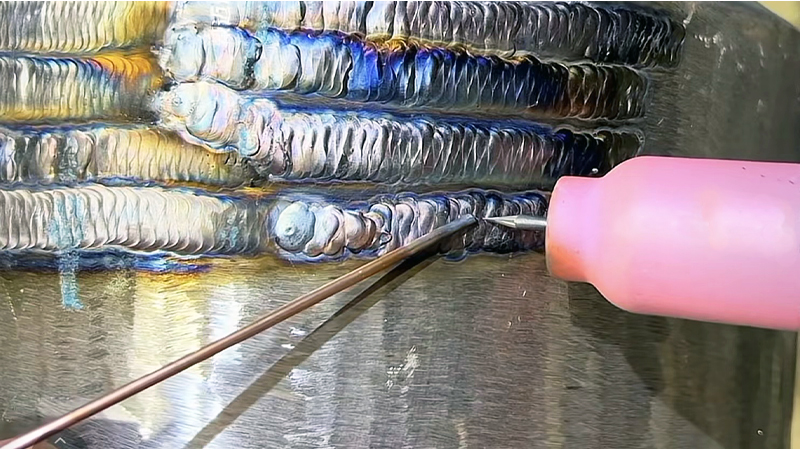

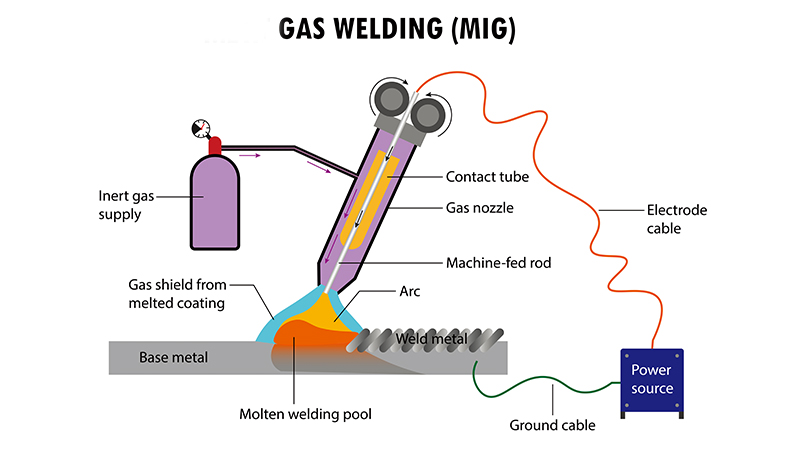

Ukuwelda kweGesi

Ukuwelda kwerhasiisebenzisa iintlobo ezimbini zerhasi: irhasi yamafutha kunye negesi ene-oxidizing. Ukutshiswa kwezi gesi kuvelisa ubushushu, obusetyenziselwa ukunyibilikisa izinto zetsimbi kunye nentonga ye-welding eqhubekayo yondliwe phakathi kwezinto ezimbini zokusebenza, ukugqiba ukudibanisa kwesinyithi.

Ukuwelda kwerhasi kuhlala kusetyenziselwa ukuwelda iintsimbi ezifana nentsimbi, ialuminiyam kunye nobhedu. Inika iingenelo ezifana nokuguquguquka kwisicelo, akukho mida kwindawo yokusebenza, kunye nokusebenza okulula. Ukongezelela, ayifuni umbane, okwenza ukuba isetyenziswe ngokubanzi kwimisebenzi yangaphandle kunye nakwiindawo zokwakha zokudibanisa isinyithi. Ukuba ufuna ukulungisa umbhobho wensimbi, i-gas welding iyona nto ikhethekileyo.

Nangona kunjalo, ukuwelda igesi kunemida yayo. Umgangatho we-weld uphenjelelwa kakhulu ngumgangatho wentonga ye-welding, kwaye amajoyina adibeneyo axhomekeke kwi-deformation. Ukongeza, ukusebenza kakuhle kwemveliso kuphantsi.

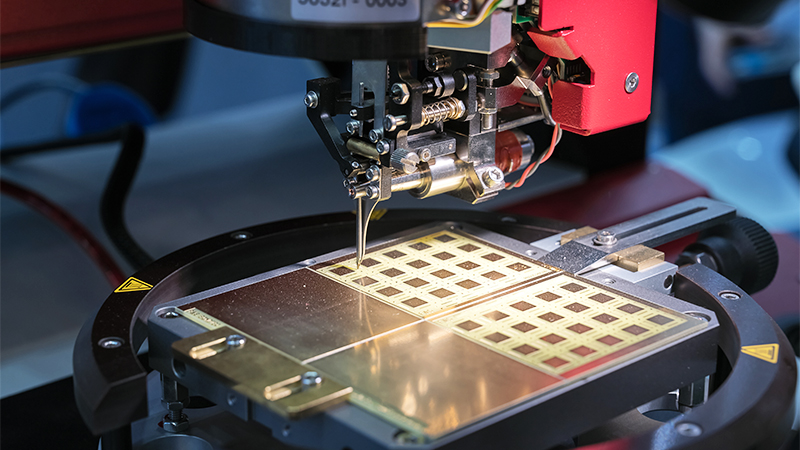

Laser Welding

Ukuwelda kweLaserisebenzisa umqa welaser njengomthombo wayo wobushushu. I-laser beam ibetha imiphetho yemisebenzi yentsimbi, ivelisa ubushushu kwaye yenze i-weld pool. Xa i-laser ihamba, imiphetho yesinyithi etyhidiweyo ipholile kwaye idibene. Le ndlela ingasetyenziselwa ukuwela i-welds, ii-welds ze-butt, kunye ne-welds ezitywiniweyo kwizicelo ezahlukeneyo zemizi-mveliso.

I-Laser welding inesantya sokuwelda ngokukhawuleza kunye nokusebenza kakuhle okuphezulu, kwaye ingasetyenziselwa ukuwelda iintsimbi ezingezizo. Bubuchwephesha be-welding obuphambili obusetyenziswa ngokubanzi kumashishini afana nokuvelisa iimoto, umbane, kunye nobucwebe. Nangona kunjalo, ayikwazi ukungena kwizinto ezityebileyo, ngoko ke ifaneleka kakhulu kwizinto ezinodonga oluncinci. Xa kuthelekiswa nezinye iindlela zokuwelda, izixhobo zokuwelda ngelaser zithande ukubiza kakhulu.

Cinezela i-Welding

Ngokungafaniyo ne-fusion welding, i-welding yoxinzelelo ifuna ukufaka umlinganiselo othile woxinzelelo kwintsimbi ngexesha lenkqubo ye-welding. Izinto zentsimbi azinyibiliki zibe yimeko engamanzi kodwa zihlala ziqinile. Uxinzelelo lwe-welding lubandakanya ukufudumeza amalungu esinyithi ukunyusa iplastiki yawo, kwaye emva koko kufakwe uxinzelelo kwintsimbi yeplastiki, okukhokelela ekudibaneni kwe-weld eyomeleleyo. Ngoko ke, uxinzelelo ludlala indima ebalulekileyo kwinkqubo.

Ngophuhliso loqoqosho lwamashishini, kuye kwavela izinto ezininzi ezintsha kunye neemveliso, nto leyo ekhokelela kutshintsho oluqhubekayo kwitekhnoloji yoxinzelelo lwe-welding. Ezona ndlela ziphambili zoxinzelelo lwe-welding okwangoku zibandakanya ukumelana ne-welding, i-diffusion welding, i-friction welding, kunye ne-ultrasonic welding.

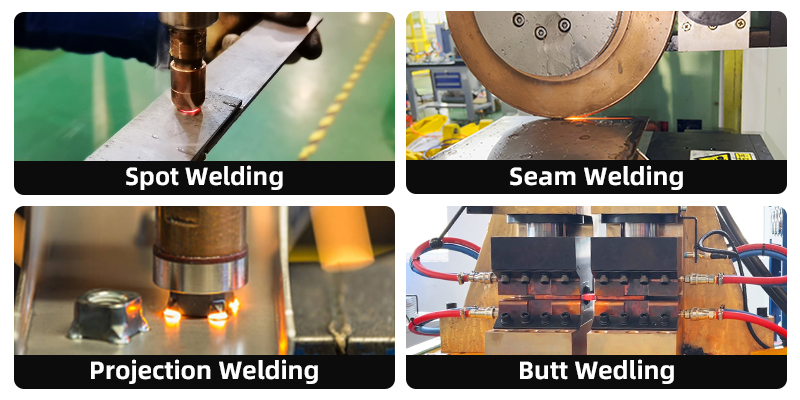

I-Resistance Welding

Ukumelana ne-weldingisebenzisa umsinga wombane ukufudumeza indawo yoqhagamshelo lwezixhobo zokusebenza zetsimbi ngelixa usebenzisa uxinzelelo ngee-electrode ukugqiba i-weld. Iqhele ukusetyenziselwa ukuwelda intsimbi engatyiwayo, ubhedu, ialuminiyam, kunye nentsimbi yekhabhoni. Ngenxa yomgangatho wayo ophezulu kunye nongaguquguqukiyo we-welding, ukumelana ne-welding kudlala indima ebalulekileyo kwimizi-mveliso yeemoto, i-elektroniki, kunye ne-aerospace. Ngokuhambela phambili kwetekhnoloji, ukuxhathisa i-welding kuye kwanda ukubandakanya i-automation, ukonyusa ngakumbi ukusebenza kakuhle kwemveliso.

I-Resistance welding inokwahlulwa ngokweendlela ezine:ukuwelda indawo, ukuwelda ingqikelelo,ukuwelda komthungo, kwayeukuwelda ngeempundu. Umzekelo, ukuba ufuna i-weld inxalenye yemoto, njengokuncamathisela i-nut kwipleyiti yesinyithi, ungasebenzisa i-welding ye-projection. Nangona kunjalo, izixhobo zokumelana ne-welding zihlala zininzi kwaye azihambiseki lula, zinciphisa ukusetyenziswa kwazo kwiisetingi ezithile. Ngalo lonke ixesha udibanisa izinto ezahlukeneyo zetsimbi okanye ubukhulu, iiparamitha kufuneka zihlengahlengiswe, zenze ukuba zifaneleke ngakumbi kwi-welding ephezulu yezixhobo zetsimbi.

Ukusasazwa kweWelding

I-welding yokusabalalisa, eyaziwa ngokuba yi-diffusion bonding, ibandakanya ukufudumeza kunye nokufaka uxinzelelo kwiindawo zetsimbi ngexesha le-welding. Le nkqubo ivumela iiathomu kunye neeathomu zezinto zetsimbi ukuba zisasazeke kwaye zibophe phantsi kobushushu obuphezulu kunye noxinzelelo. I-Diffusion welding ingasetyenziselwa zombini izinto ezifanayo kunye nezingafaniyo, eziqhelekileyo ezidibanisa ubhedu, i-aluminium, kunye nezixhobo ezidibeneyo.

Le ndlela inokuthi ngaxeshanye idibanise amajoyina amaninzi kwindibano, njenge-welding 20 layers ye-0.1 mm yefoyile yobhedu. I-welding ye-Diffusion idala amajoyina anamandla axhathisayo kwi-deformation, ngokuqhelekileyo isusa imfuno yokuqhubela phambili. Nangona kunjalo, nayo inezithintelo, kubandakanywa ukusebenza kakuhle kwemveliso kunye neendleko eziphezulu zezixhobo.

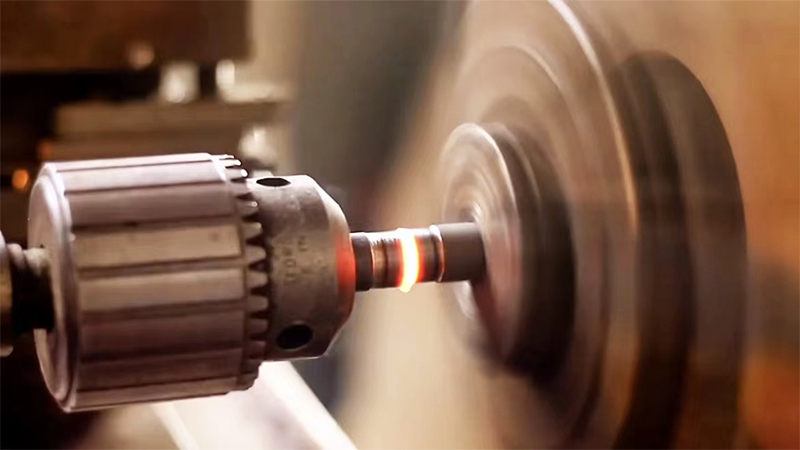

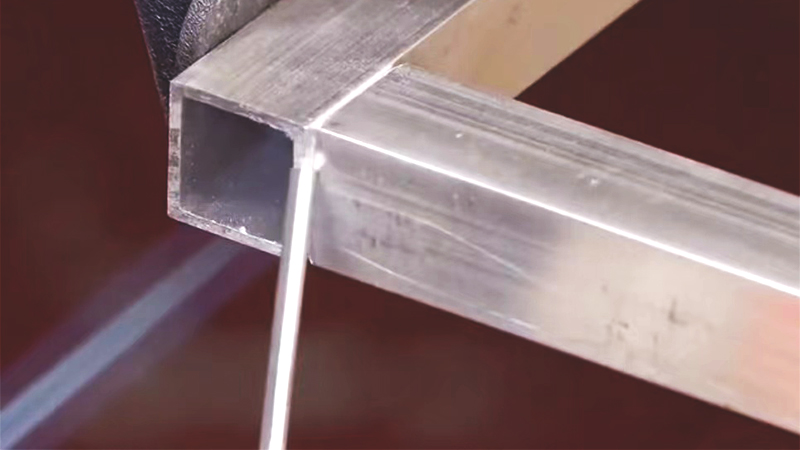

I-Friction Welding

I-friction weldingyinkqubo yokuwelda esebenzisa ubushushu obuveliswe kwintshukumo ehambelanayo phakathi kwezinto zokusebenza phantsi koxinzelelo. Yindlela esebenzayo, eyonga amandla evelisa i-welds ezikumgangatho ophezulu. Xa kuthelekiswa ne-flash butt welding, i-friction welding inommandla omncinci ochatshazelwe bubushushu kwaye ifaneleka ngakumbi ukudibanisa isinyithi esahlukileyo.

I-Friction welding yahlukile kwaye ibonelela ngezinto eziluncedo ezifana nokusetyenziswa kwamandla aphantsi kunye nobuhlobo bendalo, iyenza idume kumashishini afana nokuveliswa koomatshini, i-aerospace, kunye namandla. Nangona kunjalo, ngokuqhelekileyo ifanelekile kuphela ukudibanisa iintonga zetsimbi kunye nemibhobho yobubanzi obufanayo. Nje ukuba imilo kunye nendawo yokudibanisa yezinto zokusebenza zilungisiwe, kuba ngumngeni ukuwelda.

Ultrasonic Welding

I-Ultrasonic welding isebenzisa ii-vibrations eziphezulu-frequency eziveliswa ngamaza e-ultrasonic ukudala i-friction, deformation, kunye nobushushu kwiindawo zoqhagamshelwano zentsimbi. Uxinzelelo lusetyenziswa ngeempondo zesandi eziphezulu kunye nezantsi ukugqiba inkqubo ye-welding. Le yindlela eyodwa yokuwelda engabandakanyi umbane odlula kwizinto zokusebenza okanye kwimithombo yobushushu yangaphandle, kwaye yabelana ngeempawu ezithile kunye ne-friction welding kunye ne-diffusion welding.

Ultrasonic weldingingasetyenziselwa izinto ezahlukeneyo, kubandakanya zombini iintsimbi ezifanayo kunye nezingafaniyo ezifana nobhedu, ialuminiyam, igolide kunye nesilivere. Nangona kunjalo, isetyenziswa kakhulu ukuwelda izinto ezingezizo ezentsimbi njenge-ABS, PP, kunye nePC, apho ivelisa iziphumo ezingcono nangakumbi.

Brazing Welding

Ukugqabhukayindlela yokuwelda apho intsimbi yokuzalisa enendawo yokunyibilika engaphantsi kwaleyo yezinto zokusebenza ifudunyezwa kwaye inyibilike ukuze igcwalise izithuba phakathi kweentsimbi ezimbini, ukugqiba inkqubo yokudibanisa isinyithi. Ngokungafaniyo ne-fusion welding kunye ne-welding yoxinzelelo, le ndlela ayifuni ukunyibilika kwezinto zokusebenza okanye ukufaka uxinzelelo. Ibrazing isetyenziselwa ikakhulu ukudibanisa iworkpieces ezithenekeneyo, ezinobukhulu besithuba esisuka kwi-0.01 ukuya kwi-0.1 millimeters.

Namhlanje, ibrazing isetyenziswa ngakumbi kuwo wonke amashishini afana noomatshini, i-elektroniki, izixhobo kunye nezibane. Umgangatho wokuqhafaza ubukhulu becala kuxhomekeke kwintsimbi yokuzalisa esetyenzisiweyo. Ngoko ke, xa ubhobhoza i-workpieces zetsimbi, kubalulekile ukukhetha isinyithi sokuzalisa kunye neempawu ezintle zokumanzisa ezinokuzalisa ngokufanelekileyo amajoyina. I-Brazing ihlelwe kwi-soft brazing kunye ne-brazing eqinile ngokusekelwe kwindawo yokunyibilika kwesinyithi.

I-Soldering ethambileyo

I-soldering ethambileyo isebenzisa iintsimbi zokugcwalisa ezineendawo zokunyibilika ezingaphantsi kwama-450 degrees Celsius. Amalungu adalwe nge-solder ethambileyo anamandla aphantsi kunye nokumelana nobushushu. Iqhele ukusetyenziselwa uqhagamshelo lombane kwiimveliso ze-elektroniki ezichanekileyo kunye ne-soldering ngee-ayini ze-soldering. Ukuba iimfuno zamandla azibalulekanga kwaye indawo yokunyibilika yentsimbi yokuzalisa iphezulu kuneyentsimbi ethengiswayo, i-solder ethambileyo ingaqeshwa.

Kunzima keldering

Ukuxutywa kwesinyithi nge-high-melting-point filler metal, eyaziwa ngokuba yi-soldering enzima, isebenzisa iintsimbi zokuzalisa ezinamaqondo okunyibilika ngaphezu kwe-450 degrees Celsius. Amalungu adalwe nge-solder eqinile yomelele xa kuthelekiswa nalawo asuka kwi-solder ethambileyo. I-hard soldering ngokuqhelekileyo isebenzisa izinto ezifana nesilivere, i-aluminiyam, ubhedu kunye ne-nickel. Ukukhethwa kwesinyithi sokuzalisa kuxhomekeke kwiimpawu zezixhobo zokusebenza kunye neemfuno zokusebenza komdibaniso. I-solder enzima ngokuqhelekileyo ifaneleka kwintsimbi engenasici, i-alloys ye-aluminium, ubhedu, kunye nezinye izinto ezineemfuno zamandla aphezulu. Isetyenziselwa amajoyinti asebenza phantsi kobushushu obuphezulu kwaye ifumana usetyenziso olubanzi kwi-aerospace, i-electronics, kunye nemizi-mveliso yombane.

Ukuqukumbela

Kukho iintlobo ezahlukeneyo zentsimbi yentsimbi, kwaye ezi zikhankanywe ngasentla ziphakathi kweendlela eziqhelekileyo. Njengoko itekhnoloji ye-welding iqhubeka nokuhambela phambili, ngakumbi nangakumbi iindlela zokuwelda ziyavela. Xa uqwalasela indlela yokuwelda intsimbi, kubalulekile ukuqwalasela imiba efana nemathiriyeli yesixhobo sokusebenza, imilo yayo, indawo yokusebenza, nokunye. Ukukhetha indlela ye-welding efanelekileyo ngokusekelwe kwezi zinto kubalulekile.

Ixesha lokuposa: Jun-19-2024