Umatshini we-Spot welding ngumatshini osetyenziselwa ukudibanisa isinyithi, exhaphake kakhulu kwi-metal processing. Ngenkqubela phambili yeteknoloji yokuwelda kunye nokuphuculwa kweemfuno welding, izixhobo ukuwelda ngakumbi nangakumbi ezahlukeneyo, indawo ukuwelda umatshini luhlobo lwezixhobo ukuwelda kunye nembali ende, ukuza kuthi ga ngoku kushishino nayo indima ebalulekileyo kakhulu. Eli nqaku liza kuchaza umatshini we-welding ngokweenkcukacha, kukuthatha ukuba uqonde umgaqo wayo, iintlobo, iinzuzo, njl.

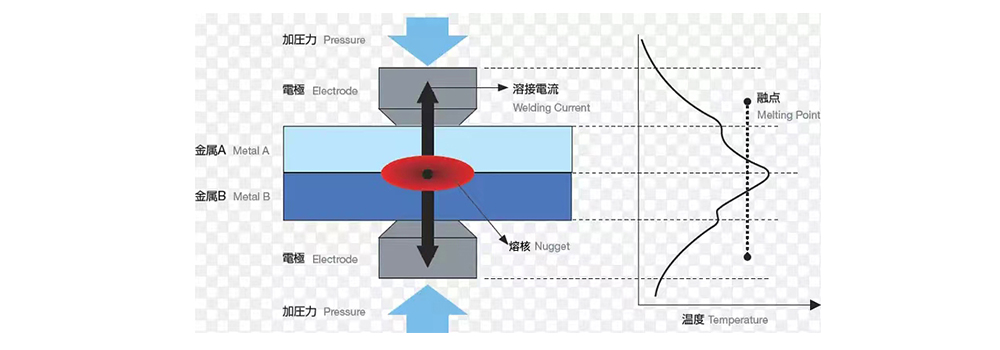

Umgaqo womatshini wokuwelda

Umatshini wokuwelda indawo luhloboukuchasa umatshini welding, esi sixhobo welding kukusetyenziswa yangoku ngokusebenzisa electrode kunye workpiece metal ukuvelisa ukumelana ubushushu ukubonelela umthombo ubushushu, ngendlela yokufudumeza kunye noxinzelelo zoqhagamshelwano ezimbini metal idityaniswe kunye. I-electrode ibamba izixhobo zokusebenza zentsimbi ezimbini ezithe gqolo, esi senzo siphunyezwa ngokufaka uxinzelelo ngoxinzelelo lomoya, ubungakanani boxinzelelo lwendawo yokusebenza ebambekayo ixhomekeke ikakhulu kubunzima bezinto kunye nokuqina kwesixhobo, kokukhona ubukhulu becala, ubukhulu becala ixabiso loxinzelelo olufunekayo, ubunzima obukhulu bezinto eziphathekayo, uxinzelelo olufunekayo. Xa udibanisa imveliso entsha nge-welder yendawo, unokuhlengahlengisa ngokuthe ngcembe uxinzelelo ukusuka kwincinci ukuya enkulu, ngexesha apho imveliso edibeneyo ivavanywa. Ude weld imveliso solder joint umphezulu agudileyo, kunye nokuqina ukuhlangabezana neemfuno, eli xesha ixabiso loxinzelelo yeyona ifanelekileyo.

Ukongeza uxinzelelo welding, ukuwelda lwangoku, ixesha welding, ukuxhathisa zoqhagamshelwano nayo iparameter ebalulekileyo indawo umsebenzi womatshini ukuwelda, zonke zichaphazela ubushushu ukuwelda, iparamitha uyahambelana omnye komnye, ukuseta iparameters ukuwelda ezifanelekileyo ukuze ekugqibeleni weld imveliso abaqeqeshiweyo.

Uhlobo lwe-welder yendawo

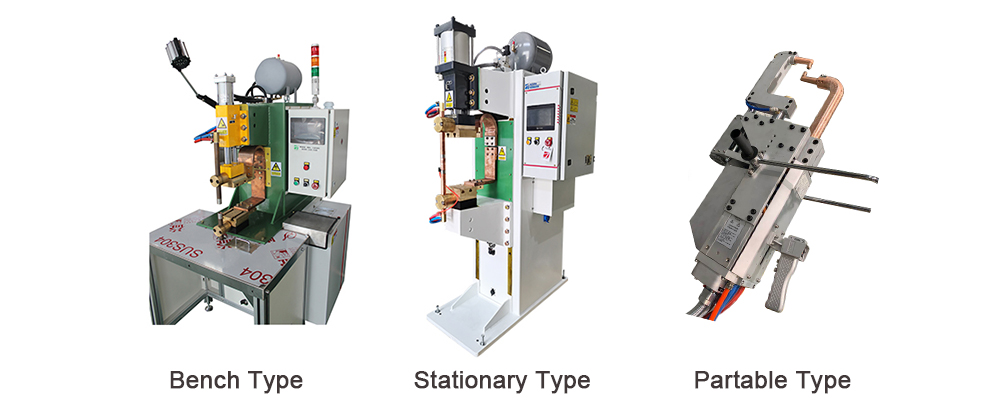

Ngenxa yeefom zokusebenza ezahlukeneyo, siye sahlula umatshini wokuwelda kwindawo2iindidi,Umatshini wokuwelda indawo osemgangathweni kunye nomatshini wokuwelda olungiselelweyo.

Indawo eqhelekileyoumshiseli

Isitulo sohlobo lwe-welder

Umatshini wokuwelda indawo yeBenchtop udla ngokuba namandla amancinci, afaneleke ngakumbi ukuwelda iimveliso zetsimbi ezincinci, ezinje ngezixhobo ze-elektroniki. Lo mzimba womatshini wokuwelda umncinci, kulula ukuwuhambisa, ubekwe ngokubanzi kwibhentshi okanye etafileni ukuze usetyenziswe, umqhubi angahlala agqibezele umsebenzi wokuwelda.

Imileindawo welder

I-fuselage inkulu kwaye inzima, umatshini awulula ukuhamba, kwaye ngokuqhelekileyo ulungiswe kwindawo ethile kwifektri, ngoko ubizwa ngokubaimileindawo welder. Xa kuthelekiswa nomatshini wokuwelda indawo desktop, iimileUmatshini wokuwelda indawo udla ngokuba namandla amakhulu, amandla okuwelda anamandla ngakumbi, kunye neenxalenye zentsimbi ngokubanzi ezinobunzima obukhulu. Ngenxa yezizathu zokhuseleko, ukutshintshwa kweenyawo kufakwe, kwaye umqhubi unokuthatha kwaye akhulule umsebenzi ngesandla.

Ephathekayoindawo weldumpu

Ikwabizwa ngokuba yi-suspended spot welder, kuba iyanqunyanyiswa ngokubanzi ukuze isebenze.Umzimba wesixhobo esiphathwayoumatshini wokuwelda indawo incinci, inokuhanjiswa idigri ezingama-360, isetyenziselwa ukuwelda akukho lula ukuhamba okanye ngaphaya komda weemveliso ezinkulu zokuwelda umatshini, ezifana nokuwelda umzimba ziya kuhlala zisebenzisa esi sixhobo. Unako ukulungelelanisa ukuphakama kwindawo efanelekileyo, ulungelelanisa inxalenye efuna ukuthungwa, ubambe i-handle switch, kwaye unokugqiba umsebenzi welding.

Umatshini wokuwelda indawo ekhethekileyo ozenzekelayo

Multi-intloko indawo welder

Ukongeza kwezi zixhobo zokuwelda zisemgangathweni, unokwenza umatshini wokuwelda ngokukodwa kwimveliso yakho ngokwemveliso yakho kunye neemfuno zokuwelda. Umzekelo, ukuba ufuna ukuwelda ishidi lentsimbi enobungakanani obukhulu, ukusetyenziswa komatshini we-welding osemgangathweni awulungele ukusebenza kwaye isantya sokuwelda sicotha. Unokucela umenzi ukuba akwenzele i-welder ye-multi-head semi-automatic spot welder, enokuthi idibanise amanqaku amaninzi ngexesha elinye, ngaloo ndlela iphucula ukusebenza kakuhle kwe-welding. Lo matshini wokuwelda udla ngokusetyenziselwa ukuwelda kweebhokisi zentsimbi, kwaye iindleko zezixhobo ziphezulu kunomatshini oqhelekileyo kuba kufuneka zilungiswe ngokwemfuno.

Umgca weXY umatshini wokuwelda indawo

Kwi-semi-automatic spot welding, itekhnoloji ehlala isetyenziswa yi-XY axis move feed. Ngamagama alula, lo matshini ngumatshini we-welding we-standard we-spot kunye ne-Xy axis itafile ehambayo, itafile iyilwe ngokobukhulu bomsebenzi. Kumsebenzi we-welding, umqhubi ufuna kuphela ukubeka i-workpiece kwi-workbench ehleliweyo, iqhosha lokutshintsha kwe-pneumatic, umatshini uya kuthumela ngokuzenzekelayo iinxalenye kwindawo ye-welding, ukubeka ngokuchanekileyo, kwaye emva koko uqalise i-welding. Lo matshini usoloko usetyenziselwa ukuwelda izakhelo zetsimbi, ishidi lesinyithi kunye ne-wire mesh.

Ukuba uvakalelwa kukuba umatshini osemgangathweni awukwazi ukuhlangabezana neemfuno zakho ze-welding, kwaye ufuna ukuphucula ukusebenza kakuhle kunye nokukhawuleza, unokuqwalasela umatshini wokuwelda okhethekileyo. Thumela nje iindawo zakho zentsimbi ukuze ubone abavelisi boomatshini bokuwelda abanjengo-Agera, siya kuxoxa ngenkqubo kunye neemfuno ze-welding kunye nawe, kwaye wenze ngokwezifiso iskimu se-welding ngokweemfuno zakho, kwaye uyilo indawo ye-welder umatshinioko kuphela kuwe.

Indlela yokukhetha i-welder yendawo efanelekileyo

Loluphi uhlobo lwe-welder ye-spot onokuyikhetha ixhomekeke kwimveliso ofuna ukuyidibanisa, ilandelwa ziimfuno zakho ze-welding.

Okokuqala, kufuneka uqonde ukuba ingaba imveliso yakho inokudityaniswa ngeteknoloji yokuwelda, imilo engaqhelekanga okanye iinxalenye ezinkulu azifanelekanga izixhobo zokuwelda, unokujongana nomenzi womatshini wokuwelda ukuba unokuwelda, unokuthatha iinxalenye kwibala umenzi welding machine for isampuli.

Ukuba ufumanisa ukuba imveliso yakho inokudityaniswa nge-welder yendawo, inyathelo elilandelayo kukumisela imodeli ye-welder. Ngeli xesha, kuyimfuneko ukujonga izinto, ubukhulu kunye nobukhulu bemveliso, iindawo ezityebileyo kufuneka zisebenzise i-welder yendawo yamandla aphezulu, kunye namacandelo anezakhelo ezinkulu ezingalunganga ukuhambisa khetha i-welder yendawo ehambayo. Unokucebisa ezinye iimbono ukwenza isixhobo se-welding sendawo nge-automation.

Izinto eziluncedo kwi-spot welder

Isantya se-welding sikhawuleza.Xa kuthelekiswa nezinye izixhobo zokuwelda ezifana umatshini welding laser, indawo welding umatshini welding isantya ngokukhawuleza kakhulu, ingongoma ixesha welding inokugqitywa ngomzuzwana omnye, kwaye namanqaku amaninzi anokudityaniswa ngaxeshanye, ukuphucula kakhulu ukusebenza kakuhle kwe-welding.

Iimpawu ze-welding ezincinci.Ngethuba nje ulungelelanisa iiparamitha ezifanelekileyo, imveliso edibeneyo intle, i-deformation encinci, akukho burrs, ngokubanzi akufuneki ukuba wenze inkqubo emva kwe-welding, ukugcina inkqubo yokucubungula.

Akukho mfuneko yokuzalisa i-solder.I-welder yendawo idinga kuphela ukulungelelanisa iziqwenga ezibini zetsimbi ukuba zidibanise, kwaye zinokuthi zifakwe ngaphandle kokongeza nayiphi na i-solder. Ezinye iindlela ze-welding zifana ne-arc welding, kuyimfuneko yokongeza i-solder kwinkqubo ye-welding kwi-welding, ngale ndlela isantya se-welding sicotha, kwaye iimfuno zobuchwepheshe ze-welder ziphezulu.

Ukusebenza okulula.Ukusebenza komatshini we-welding welding kulula kakhulu, kufuneka ulungelelanise iiparameters ze-welding phambi kwe-welding, ungaqala ukudibanisa i-welding enkulu, lo msebenzi we-welding unokugqitywa ngabasebenzi abaqhelekileyo.

Ukusetyenziswa komatshini wokuwelda indawo

Izinto zokuwelda

Umatshini we-spot welding usetyenziselwa ukuwelda izinto zetsimbi, ezihlala zisetyenziselwa ukuwelda insimbi engenasici, intsimbi ephantsi yekhabhoni, intsimbi, ubhedu, i-aluminiyam kunye nezinye izinto, ukongeza kwi-welding yento efanayo, inokudibanisa isinyithi esingafaniyo. Ukongeza kwisheet metal welding, ukuwelda okudityanisiweyo kweendongomane, iibholiti kunye namaphepha anokusebenzisa i-welders spot.

Isicelo seshishini

Umatshini we-spot welding usetyenziswa kakhulu kwishishini, kwaye ukusetyenzwa kwesinyithi kunokubona umzobo wawo. Umatshini we-Spot welding usetyenziswa ikakhulu kwimveliso yeemoto, i-elektroniki kunye nombane, izixhobo zasekhaya, iikhabhathi zentsimbi, ukwenziwa koomatshini kunye namanye amashishini. Nanini na xa ufuna uqhagamshelo lwentsimbi, uya kusebenzisa i-welder yendawo.

Isishwankatheloubumnandi

Oku kungasentla kuyintshayelelo emfutshane kumatshini wokuwelda, ukuba ufuna umatshini wokuwelda ofanelekileyo, eli nqaku kufuneka likwazi ukufumana impendulo. Ukukhetha umatshini wokuwelda indawo efanelekileyo kubaluleke kakhulu, umatshini wokuwelda indawo elungileyo unokudala imveliso ekhuphisanayo kuwe, umatshini ombi uya kunciphisa ukusebenza kwakho kakuhle. Ungaqhagamshela kwakhonaAgeraabavelisi koomatshini bokuwelda indawo, siya kucebisa imodeli efanelekileyo kuwe.

Ixesha lokuposa: Jul-26-2024