Ukuwelda indawoluhlobo lokumelana nokuwelda, njengenkqubo esekwe kakuhle esetyenziselwa ukudibanisa isinyithi ezahlukahlukeneyo, iyenza ibe yindlela ebalulekileyo yokusebenza kwesinyithi yanamhlanje. Eli nqaku libonelela ngeengcebiso zokufezekisa ii-welds ezinamandla, ezinomtsalane, kunye nezizinzileyo:

Khetha eKuneneIbalaUkuweldaUmatshini

Ukukhetha isixhobo sokuwelda esifanelekileyo sokuxhathisa kubalulekile. Kuphephe oomatshini abakhulu kakhulu abaneempawu ezininzi, njengoko oku kunokumosha utyalo-mali. Ngokufanayo, musa ukukhetha umatshini owaneleyo, njengoko unokungavumeli ukwanda kwexesha elizayo okanye ube nokumelana nokudinwa okuhle.

Olona khetho lungcono ngumatshini okwaziyo ukwenza i-welding enzima, malunga ne-25% yesakhono esongezelelweyo kwi-welding yangoku kunye noxinzelelo olungaphaya kwangoku.sheet metal welding.

Ukusebenzisa umatshini omkhulu kunokubangela imiba emininzi njengomatshini omncinci kakhulu. Ngokomzekelo, ukuba i-diameter ye-cylinder inkulu kakhulu, kufuneka isebenze kuxinzelelo lomoya olungaphantsi kwe-0.2 MPa ukufezekisa uxinzelelo olufunekayo lwe-welding. Oku kunokukhokelela ekuphenduleni kakubi kwindlela yokusetyenziswa koxinzelelo. Ukuba i-cylinder ayisebenzi ngokukhawuleza xa isinyithi sifikelela kwisimo seplastiki kwaye sidinga ukulungiswa ngokukhawuleza, amandla e-weld kunye nokuzinza kunokubandezeleka.

Iinkampani ezininzi, ukuze kube lula ukulawula izixhobo kunye neeparitha ze-welding ezifanayo, khetha izixhobo ezisekelwe kwiimodeli eziqhelekileyo kuneemfuno zenkqubo ye-welding. Oku kunokukhokelela ekusebenzisaneni kakubi xa udiza ezona ndawo zikhulu nezincinci. Le yimpazamo eqhelekileyo yeenjineli ezingenamava. Indlela echanekileyo kukutshatisa ubungakanani besixhobo kwizinto zokusebenza ezidityanisiweyo.

Qeqesha ngaphakathiIbalaUkuwelda

Okokuqala, kubalulekile ukuqeqeshwa kwimigaqo ye-welding kunye nobuchule. Ukuqonda imigaqo ye-resistance spot welding ibalulekile ekulungiseni ngokuchanekileyo iinkqubo ze-welding kunye nokusebenzisa izixhobo ngokufanelekileyo.

I-spot welding inokubonakala ilula, njengoko kubonakala ngathi nabani na unokusebenza kwaye ahlengahlengiseumatshini wokuwelda indawo: beka iindawo phakathi kwe-electrodes, cinezela iqhosha lokuqala, kwaye iindawo zidibene kunye. Nangona kunjalo, oku kuyakhohlisa. Kubalulekile ukuqonda ukubaluleka kwezinto ze-welding kunye neeparamitha kwaye ulungelelanise nganye kwixabiso layo eliphezulu.

Yicinge njengokupheka: izithako ezifanayo, kodwa i-seasonings eyahlukeneyo, amanqanaba obushushu kunye namaxesha okupheka anokuvelisa iincasa ezahlukeneyo kakhulu!

Izinto ezintathu eziphambili ze-welding yendawo ye-welding current, ixesha le-welding, kunye noxinzelelo lwe-welding. Iiparamitha ezongezelelweyo ziquka ixesha loxinzelelo lwangaphambili, ixesha lekhefu le-welding, kunye nexesha lokubamba i-post-welding.

Ngokudibanisa ezi parameters, unokufezekisa i-welding eqinile, ephakathi, okanye ethambileyo, ekhokelela kwiziphumo ezahlukeneyo zokuwelda, ezinje:

Iimpawu ezinzima:I-deformation encinci yecandelo, impembelelo yokushisa ephantsi, isantya esikhawulezayo se-welding, kodwa ifuna amandla aphezulu, amandla, kunye nezixhobo zoxinzelelo oluphezulu.

Iimpawu ezithambileyo:Inxalenye ebalulekileyo ye-deformation, i-weld indentation enzulu, i-discoloration, isantya esincinci se-welding, kodwa amandla aphantsi kunye neemfuno eziqinileyo zesixhobo.

Inkcazo ephakathi:Iziphumo kunye neemfuno zezixhobo ziwela phakathi kwezi zimbini zigqithisayo zingentla.

Iincwadi zobuchwephesha ezifana ne "Welding Handbook" zibonelela ngeengcebiso zeparameter, kwaye iinjineli zenkonzo yobuchwephesha ye-Agera zibonelela ngoqeqesho lobuchwephesha kunye nesikhokelo kubasebenzisi.

Khetha eKuneneSpot WeldingIi-electrodes

Ukuthelekisa imathiriyeli ye-electrode kunye nenxalenye yemathiriyeli kubalulekile kwiziphumo ezizezona zilungileyo ze-welding kunye nokusebenza kakuhle kwamandla.

Ukuwelda indawoaluminiyamkwayeamashiti enziwe ngesinyithi, sebenzisa i-alumina-dispersed copper electrode, exhathisa ukunamathela.

Kubayenziwe ngentsimbi eshayinayokunye namaphepha entsimbi ephantsi kwekhabhoni, sebenzisa i-electrode yobhedu ye-chromium zirconium, ebonelela ngeendleko eziphezulu.

Kubaubhedu, i-tungsten kunye ne-molybdenum electrode ziyadingeka ukuncedisa nge-welding ngenxa yokushisa kwazo.

Uyilo kunye nokuveliswa kweemilo ze-electrode nazo zibalulekile, njengoko zichaza ubungakanani kunye nokubonakala kwe-weld nugget kunye namandla ayo.

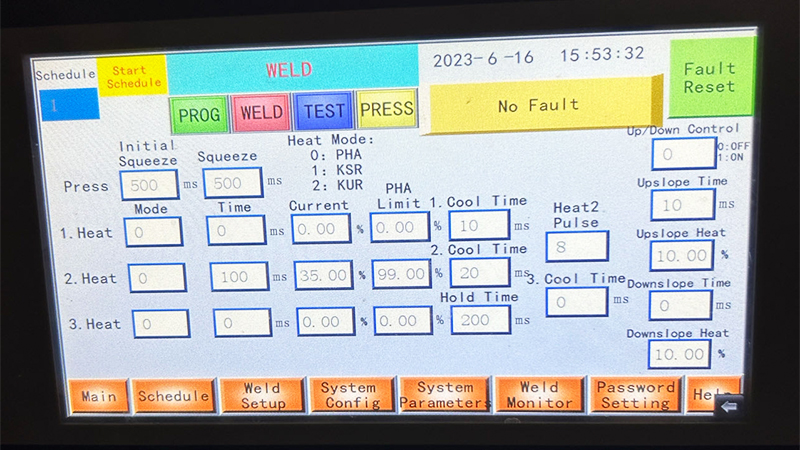

Misela i-Welding Parameters

Iiparamitha ze-Welding zingasetwa ngokusekelwe kumava okanye idatha evela kwimithombo yoluntu. Ukuba akukho zimbekiselo zikhoyo, ungafumana kuphela ezona parameters zintle zokuwelda ngokusebenzisa iiweld ezininzi zolingo ezinesetingi ezahlukeneyo. Xa uvavanya, landela le migaqo:

Qala ngokuNcinci: Qala ngokugcina, amaxabiso amancinci kwiiparameters ezifana ne-welding yangoku, ixesha, kunye noxinzelelo, kwaye ngokuthe ngcembe wandise. Le ndlela inceda ukuphepha umonakalo kwisixhobo, i-electrodes, kunye neengxenye.

Lungisa iParameter enye ngexesha: Ukulungelelanisa iiparitha ezininzi ngaxeshanye kunokukhokelela kwizigwebo ezingalunganga, ngakumbi kubaqhubi abangenamava. Ukuba olunye uhlengahlengiso alusebenzi, zama olunye ngelixa ujonga ngononophelo utshintsho kumgangatho we-welding.

Vumela iParameter Margins: Qinisekisa ukuba kukho umda weparameters ukulungiselela ukwahluka kumacandelo.

Emva kokuba iiparameters ze-welding ziqinisekisiwe, qinisa ezi datha kwaye uzisebenzise njengesiseko sokuvelisa.

Gcina i-Electrodes

Rhoqo lungisa ii-electrode ezigogekileyo ukuze uzigcine kubungakanani obuyilwe ekuqaleni kwaye ucoce ubumdaka kunye neentsalela zengxubevange yobhedu kumphezulu wazo. Olu londolozo lubalulekile kwi-welding ezinzileyo.

I-Electrodes esebenza phantsi koxinzelelo oluphezulu kunye nobushushu bunokukhubazeka, ukwandisa indawo yabo yokudibanisa kunye namalungu kunye nokunciphisa ubuninzi be-welding yangoku. Ukongeza, iingubo ezingaphezulu, i-oyile, kunye nomhlwa ukusuka kwiindawo zinokubambelela kwii-electrode, ukwandisa ukuchasana noqhagamshelwano kunye nokunciphisa i-welding yangoku. Le miba ichaphazela ngokuthe ngqo umgangatho we-welding.

Ukusebenzisa isinxibo esikhethekileyo se-electrode kunokubuyisela ngokukhawuleza ukumila kwe-electrode kwaye kususe ubumdaka obungaphezulu. Gwema ukusebenzisa ifayile yokucoca ngesandla, njengoko ayikwazi ukuqinisekisa ukuma okufanelekileyo kunye nokugqitywa kwendawo ye-electrodes.

Sebenzisa i-Welding Inspection Equipment

Amalungu e-spot welding aqhelekanga kuvavanyo olungonakalisi. Iindlela zokuhlola eziqhelekileyo ziquka ukuhlolwa okubonakalayo, i-torque wrenches (ye-welding nuts), oomatshini bokuvavanya i-tensile, kunye nabavavanyi be-metallographic.

Uvavanyo lwe-Tensile kunye noKunyanzeliswa: Yenza ezi mvavanyo ngaphambi kokuba uqale usuku olupheleleyo lwemveliso ukuqinisekisa ukuthembeka kweeparitha ze-welding kunye nesethi yedatha yovavanyo. Ekupheleni kweshifti nganye, vavanya iinxalenye ezidityanisiweyo kunye neeparamitha zangoku kwakhona ukuqinisekisa ukuhambelana. Kwiindawo ezibalulekileyo ezineemfuno eziphezulu zomgangatho, ukwandisa ukuphindaphinda kovavanyo olonakalisayo.

Ukujongwa kweNkqubo: Ukusebenzisa iimonitha zomgangatho we-welding yenye inketho, eya ixabisa ngakumbi kwaye isetyenziswa ngokubanzi. Ngokubeka iliso kwiiparamitha ze-welding ngexesha langempela kunye nokubeka imida ephezulu kunye nesezantsi, nakuphi na ukuphambuka kunokubangela i-alamu, ukunciphisa iziphene ze-welding. Ezi datha ze-welding zinokugcinwa ukuze zilandeleke umgangatho.

ULondolozo lwarhoqo kunye noHlolo

Emva kokusetyenziswa kwexesha elide, izixhobo zokuwelda zeSpot zifuna ukujongwa rhoqo kwezi ndawo:

- ISekethe yokuQhubela:I-welding spatter inokuhlasela iindawo ezikhuselweyo kunye nezithuba, ezibangela ukucima, ukunciphisa kunye nokunciphisa i-welding current. Susa i-weld slag. Ukutshintsha rhoqo kwe-electrode kunokunxiba kunye ne-oxidize uqhagamshelo lwe-conductive, olufuna ukuphinda kulungiswe. Qinisa iibholithi kwimitya yobhedu ethambileyo kunye nemivalo yobhedu eqinile ukunqanda ukukhululeka ekusebenziseni ixesha elide.

- IsiKhokelo se-Welding Cylinder:Jonga intshukumo egudileyo kunye nezikhewu. Ukutyibilika okungalunganga kuchaphazela ukulandelwa kwe-weld; izithuba ezigqithisileyo zichaphazela ukumila kwe-weld kunye nokulungelelaniswa kwenxalenye.

- ISekethe yaManzi:Qinisekisa ukuhamba kakuhle kwamanzi. Coca iimitha zokuhamba ukuze kucace, khangela indlela yokuhamba nganye, kwaye ucoce izithintelo okanye utshintshe imibhobho. Amanzi angonelanga okupholisa anokuthi agqithise i-transformers kunye ne-electrode, ukunciphisa ixesha lokuphila okanye kubangela ukudinwa. Khangela kwaye ulungise iindawo ezivuzayo.

- I-Welding yangoku:Qinisekisa i-welding current kunye nomhloli weqela lesithathu ukuqinisekisa ukuba iyahambelana nemigangatho. Ukusetyenziswa ixesha elide kunokunciphisa imveliso yangoku, ngoko ke ukuvavanya rhoqo kunye nokuphuculwa okanye ukulungiswa kunokufuneka.

- ISekethe yoMoya:Jonga kwaye ulungise ukuvuza komoya, njengoko ukuvuza kubangela uxinzelelo olungazinzanga kunye nokulahleka kwamandla.

- Ucoceko:Gcina izixhobo zicocekile. Iimpawu ezicacileyo kunye nezixhobo ezicocekileyo zinciphisa iimpazamo zabantu.

Ihlobo

Ezi zezinye iingcebiso kubasebenzisi bezixhobo zokumelana ne-welding. Ngaphezulu kweminyaka engama-20 yamava kushishino ukuwelda, sinikezela uluhlu olupheleleyo lweenkonzo, kuquka ukulungiselela isampuli welding, ukhetho umatshini, isiko non-standard automated izixhobo welding, ufakelo kunye nokugunyazisa, ukugcinwa, izixhobo ezixhasayo, kunye namacandelo. Zive ukhululekile ukuqhagamshelana nathi!

Ixesha lokuposa: Jul-09-2024