Ngenkqubela phambili eqhubekayo yenzululwazi kunye nobuchwepheshe kunye nokunyuka kokuphuculwa kwemveliso yemveliso, iteknoloji yokumelana ne-welding, njengendlela ebalulekileyo ye-welding, isetyenziswe ngokubanzi kwiinkalo ezahlukeneyo. Nangona kunjalo, itekhnoloji yemveli yokumelana ne-welding ineengxaki ezithile, ezinjengokuchaneka kolawulo oluphantsi, ukusetyenziswa kwamandla aphezulu kunye nomgangatho we-welding ongazinzanga. Ukuze kusonjululwe ezi ngxaki, itekhnoloji yedijithali yaziswa kwitekhnoloji yokumelana ne-welding, ephucula kakhulu inqanaba le-automation kunye nomgangatho we-welding of resistance welding.

welding Digital ukumelana

I-Digital resistance welding luhlobo lweteknoloji ye-welding esebenzisa iteknoloji yedijithali ukulawula ngokuchanekileyo kunye nokwandisa inkqubo yokumelana ne-welding. Inokuqonda ukujonga ixesha lokwenyani kunye nohlengahlengiso oluzenzekelayo lwenkqubo ye-welding ngokulungiswa kwedijithali yeeparamitha ze-welding, idatha yenkqubo, imeko yezixhobo kunye nolunye ulwazi. I-Digital resistance welding inezi mpawu zilandelayo:

1. Ukuchaneka kokulawula okuphezulu: i-digital resistance welding ingakwazi ukulawula ngokuchanekileyo i-welding yangoku, i-voltage, ixesha kunye nezinye iiparitha zokuqinisekisa ukuzinza kunye nokuhambelana komgangatho we-welding.

2. Iqondo eliphezulu lokuzenzekelayo: inkqubo ye-digital ye-welding welding inokuqonda ulawulo oluzenzekelayo lwenkqubo ye-welding, ukunciphisa ukungenelela ngesandla kunye nokuphucula ukusebenza kakuhle kwemveliso.

3. Ukugcinwa kwamandla kunye nokukhuselwa kwendalo: Ngokulungisa iiparitha ze-welding kunye neenkqubo, i-digital resistance welding inokunciphisa ukusetyenziswa kwamandla kunye nokunciphisa ukukhutshwa kwezinto ezingcolileyo ezifana ne-steal gas kunye ne-slag.

4. Ukulandelelwa okunamandla: inkqubo ye-digital ye-welding welding inokurekhoda idatha kwinkqubo ye-welding, inikezela ngenkxaso eqinile yokulandelela umgangatho wemveliso.

Ukubaluleka kokufakwa kwedijithali kwiukumelana welding

1. Ukuphucula umgangatho we-welding: iteknoloji yedijithali inokulawula ngokuchanekileyo iiparitha ze-welding kunye neenkqubo zokuqinisekisa ukuzinza kunye nokuhambelana komgangatho we-welding kunye nokuphucula umgangatho wemveliso.

2. Ukuphucula ukusebenza kakuhle kwemveliso: itekhnoloji yedijithali inokuqonda ulawulo oluzenzekelayo kunye nokwenza ngconoinkqubo welding, ukunciphisa ungenelelo lwezandla, kunye nokuphucula ukusebenza kakuhle kwemveliso.

3. Ukunciphisa iindleko zokuvelisa: Ngokulungisa iiparamitha ze-welding kunye neenkqubo, i-digital resistance welding inokunciphisa ukusetyenziswa kwamandla kunye nokusetyenziswa kwezinto eziphathekayo, kunye nokunciphisa iindleko zokuvelisa.

4. Ukomeleza ukukhuphisana kwamashishini: iteknoloji yedijithali yokumelana ne-welding inokuphucula inqanaba lobugcisa kunye nenqanaba lolawulo lwamashishini, kunye nokwandisa ukhuphiswano lwemarike kunye nokukwazi uphuhliso oluzinzileyo lwamashishini.

Ukusetyenziswa kwedijithali kwi-welding yokumelana

1. Ulawulo lweparamitha yeWelding

Kwinkqubo yokumelana ne-welding, ukulawulwa kweeparamitha ze-welding kunempembelelo ebalulekileyo kumgangatho we-welding. Itekhnoloji yedijithali inokubeka iliso kwaye ihlengahlengise i-welding yangoku, i-voltage, ixesha kunye nezinye iiparamitha ngexesha langempela ukuqinisekisa ukuzinza kunye nokuhambelana kwenkqubo ye-welding.

2. Ukulungiswa kwenkqubo ye-Welding

Itekhnoloji yedijithali inokulungelelanisa ngokuzenzekelayo iiparameters zenkqubo ye-welding ngokwezixhobo zokuwelda, imilo ye-workpiece kunye nobukhulu kunye nezinye izinto ukuze ziqonde ukulungelelaniswa kwenkqubo ye-welding. Ngokusebenzisa ukulinganisa kunye nohlalutyo lwedatha, inkqubo ye-digital ye-welding welding inokuqikelela intsimi yobushushu, intsimi yoxinzelelo kunye nolunye utshintsho kwinkqubo ye-welding, kunye nokubonelela ngesiseko senzululwazi sokuphucula inkqubo. Ukongeza, itekhnoloji yedijithali inokuphinda ifezekise ukubeka iliso kude kunye nokuxilongwa kwempazamo yenkqubo ye-welding, ukuphucula ukuthembeka kunye nobomi benkonzo yezixhobo.

3. Ukuhlolwa komgangatho we-welding

Itekhnoloji yedijithali inokubeka iliso kwaye ivavanye umgangatho we-welding ngexesha langempela. Ngokuqokelela i-voltage, yangoku, iqondo lokushisa kunye nezinye iiparameters kwinkqubo ye-welding, inkqubo ye-digital resistance welding system inokugweba ukuba umgangatho we-welding uyahlangabezana neemfuno. Kwangaxeshanye, itekhnoloji yedijithali nayo inokuqhuba uvavanyo olungabhubhiyo lwamalungu adityanisiweyo ukufumana iziphene kunye nobungozi obufihliweyo kwinkqubo ye-welding.

4. Ulawulo olukrelekrele

Inkqubo yedijithali yokumelana ne-welding inokuqonda ulawulo olukrelekrele lwenkqubo ye-welding. Ngokudityaniswa kwe-Intanethi yeZinto, idatha enkulu, i-computing yefu kunye nobunye ubuchwepheshe, inkqubo yedijithali yokumelana ne-welding inokufikelela ekubekweni kweliso ixesha lokwenyani lemeko yezixhobo, ukuxilongwa kwempazamo kunye nokugcinwa kwesilumkiso kwangethuba. Ukongezelela, iteknoloji yedijithali nayo inokuqonda ukubonakaliswa okubonakalayo kunye nohlalutyo lwedatha yenkqubo ye-welding, ukubonelela ngenkxaso eqinile kwizigqibo zokuvelisa.

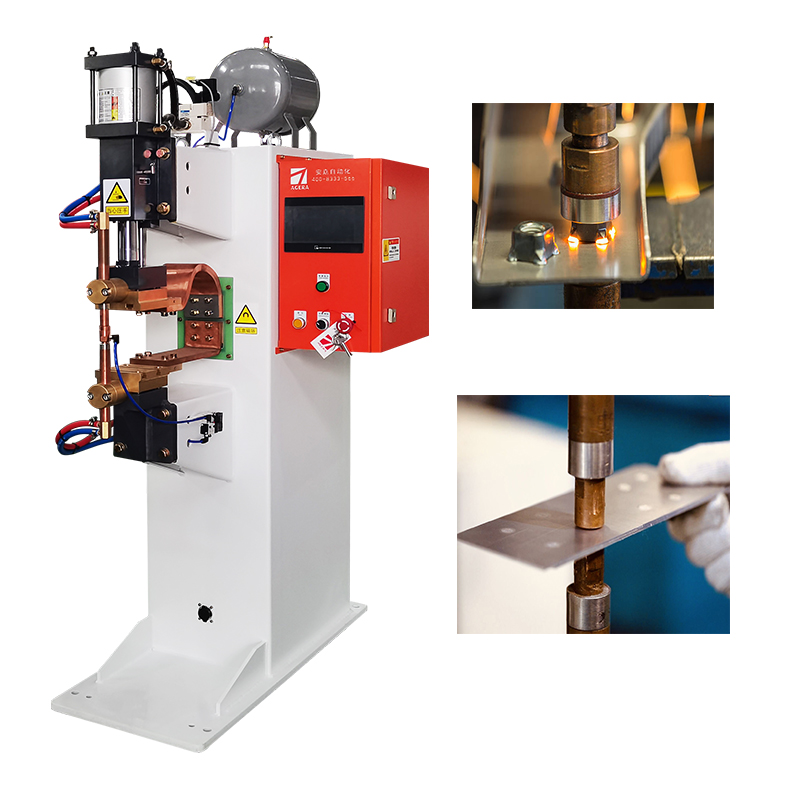

Njengomboneleli wesisombululo sonxibelelwano lwesinyithi ohamba phambili kwihlabathi, i-Agera iphinda iphonononge indlela yophuhliso ye-digital resistance welding, kwaye ngo-2022, yaphuhlisa kwaye yavelisa inkqubo yokubeka iliso yexesha lokwenene ye-welding HRC650, esisixhobo esichanekileyo. Ingasetyenziselwa ukukhangela kwexesha langempela-ixesha langempela langoku, i-voltage yesibini, ukuchasana ngokudibeneyo, ukuchithwa kwe-electrode, idatha yoxinzelelo lwe-electrode kunye neengqungquthela ezichaphazela umgangatho we-weld, kunye nomda wokukhawulela idatha nganye inokusekwa ngabanye. Ukuba idatha idlula ixabiso elichaziweyo, unokukhupha i-alamu kwaye usete ijika lemvulophu.

Ukusetyenziswa kwedijithali kwitekhnoloji yokumelana ne-welding ibe yinto engenakuthintelwa kuphuhliso lweshishini. Ngophuhliso oluqhubekayo kunye nokuphuculwa kobugcisa bedijithali, iteknoloji ye-welding ye-resistance buya kufezekisa inkqubo ye-welding esebenzayo, echanekileyo kunye nehlakaniphile. Kwixesha elizayo, i-Agera iya kuqhubeka nokuphonononga indlela ye-digital resistance welding kunye nokubonelela ngenkxaso eqinileyo yokuguqulwa kunye nokuphuculwa kwemveliso yemizi-mveliso.

Ixesha lokuposa: Jun-13-2024