Ukuwelda ngeempunduisetyenziswa ngakumbi nangakumbi ekusetyenzweni kwentsimbi yanamhlanje, ngokusebenzisa itekhnoloji ye-butt welding, intsimbi efanayo okanye isinyithi esingafaniyo esinjengobhedu kunye ne-aluminiyam inokuqina ngokuqinileyo kunye. Ngophuhliso lweshishini, itekhnoloji ye-welding ye-butt isetyenziswa ngakumbi kumbane kunye nombane, izithuthi zamandla amatsha kunye namanye amashishini. Inqaku elilandelayo liza kuphendula ulwazi lwe-butt welding yakho ngokweenkcukacha.

IsisekoCngaphandle kweButtWelding

Oku kubizwa ngokuba yi-welding ye-butt kukubeka iziphelo ezimbini zokusebenza ngokumalunga omnye komnye, zifake uxinzelelo ngaxeshanye, sebenzisa i-welding yangoku ukutshisa, kwaye emva koko wenze i-welding joint phantsi kwesenzo soxinzelelo, i-automation esebenzayo kwaye kulula ukuyifumana. indlela welding inkqubo.

The Iintlobo of ButtWelding

Ukuwelda ngeempundu kohlulwe kakhuluukuwelda ngeempundukwayei-flash butt welding

I-resistance butt welding

I-Resistance butt welding luhlobo lwe-welding yesigaba esomeleleyo kwimo yobushushu obuphezulu beplastiki, kwaye uqhagamshelo oludibeneyo lunokuthi lube yikristale kunye nokusasazwa okulinganayo ngokwenyani, kodwa zonke ziluqhagamshelo oluluqilima lwesigaba.

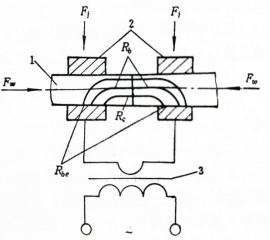

Umgaqo wokumelana ne-butt welding kunye nokwakheka ngokubambisana kuboniswe kuMfanekiso 1.

Umzobo 1. Ukumelana ne-butt welding schematic diagram

1- Ukutshisa

2- Electrode

3- I-Solder resistance transformer

I-4-Ff-i-clamping force

Fw- amandla okwenza

Rb- ukuxhathisa i-weldment

RC-Ukuchasana noQhagamshelwano

I-Rbe- Ukuchasana noqhagamshelwano phakathi kwe-weldment kunye ne-workpiece

I-Flash Butt Welding

Undoqo wodibaniso lwe-flash butt welding joint lufana nelo lokumelana ne-butt welding joint, ekwaludibaniso lwesigaba esiluqilima, kodwa inkqubo yokwakheka ineempawu zayo. Ekupheleni kweflash, i-liquid metal layer yenziwe kwisiphelo sobuso. Ngethuba lokubumba okuphezulu, isiphelo sobuso besinyithi siqala ukuhlanganiswa phantsi kwesigaba solwelo. Emva koko umaleko wesigaba solwelo uya kucudiswa ngaphandle kobuso besiphelo esidibeneyo phantsi kwesenzo soxinzelelo oluphezulu lokubumba.Emva kweumatshini welding we-flash buttiindawo ezidityanisiweyo, umdibaniso womelele kakhulu, njengetyhubhu yesinyithi ngokusebenzisa i-flash welding, emva kokoumatshini wokugoba ityhubhuukugoba kwi-joint, i-joint ayiyi kuphuka.

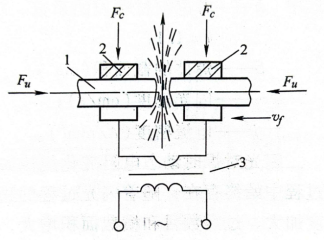

Umgaqo we-flash butt welding kunye nokwakheka ngokubambisana kuboniswe kuMfanekiso 2:

Umfanekiso 2. Umzobo we-flash butt welding schematic diagram

1- Ukutshisa

2- Electrode

3- I-Solder resistance transformer

4- Fc- clamping force Fu- forging force Vf flash speed

Izinto ezilungileyo zeButtWelding

a) Isixhobo sokumelana ne-welding silula, iiparamitha ezimbalwa ze-welding, kulula ukuyiqonda, kulula ukufikelela kulawulo oluzenzekelayo;

b) Ukuncitshiswa okuncinci kweendawo zokumelana ne-butt welding, izinto zokulondoloza, ii-burrs ezincinci, ezilungele ukwenza lula inkqubo yokugqibela;

c) i-flash butt welding inobuchule obuphezulu bokushisa, inokuwelda iindawo ezinkulu, kwaye isetyenziselwe ukuwelda imibhobho yerhasi enommandla onqamlezileyo oyi-100000mm2;

d) i-flash butt welding ngenxa yokuba i-lintel ikhona ixesha elifutshane, i-milliseconds embalwa kuphela, indawo yayo iyatshintsha ngokungaqhelekanga, kwaye ixesha elipheleleyo lokufudumeza kwisiphelo sobuso be-weldment lifana kakhulu, ngoko ke ukuwelda okuqhubekayo akukwazi ukuwelda kuphela. icandelo elidibeneyo, kodwa kunye ne-welds welds kunye namacandelo awandisiweyo (njengamaphepha amancinci, njl.);

e) Ekupheleni kwe-flash, umaleko obhityileyo wentsimbi engamanzi uya kwenziwa phezu komphezulu we-weldment, ukuze ukungcola kwe-oxide kumphezulu kube lula ukukhupha kunye nentsimbi engamanzi kwinqanaba eliphezulu le-interface. ukuba i-flash butt welding joint ikumgangatho ophezulu, kwaye iintlobo ze-welding zingaba ngaphezulu, kunye neentlobo ezahlukeneyo zezinto ezinokuthi zidibanise.

f) Akukho sigcwalisi sifunekayo kwinkqubo ye-welding, kwaye izinga lokusetyenziswa kwezinto eziphathekayo liphezulu;

Ukusetyenziswa kweButtWelding

UkuVeliswa kweeMoto

Umfanekiso 3. Automobile cardan shaft iqokobhe flash butt welding

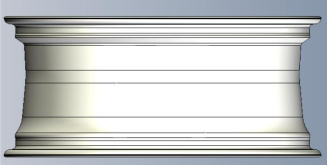

Umzobo 4. Automobile, isithuthuthu ivili flash butt welding

Ishishini le-Aerospace

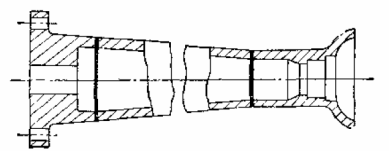

Umzobo 5. Ukuwelda ngentonga yenqwelomoya

Ishishini lePetrochemical

Umzobo 6. Imibhobho yesinyithi i-butt welding

Intsimi yobunjineli bokwakha

Umzobo 7. Ukuphela kweplate flange butt welding

Ishishini lokwakha iinqanawa

Umfanekiso 8. I-anchor chain i-butt welding

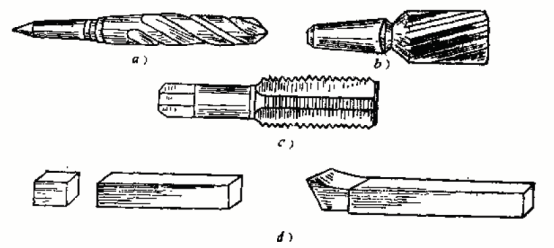

izixhobo zehardware

Umzobo 9. Isixhobo se-butt welding

SukucaciswaPiiameters ngaphakathiButtWeldingPirowusi

Xa iiparameters ezifanelekileyo ze-butt weldings specitions zikhethwa, amajoyina asemgangathweni ophezulu kunye neepropati eziphantse ezifana nezixhobo ezisisiseko zinokufumaneka.

a) Ezona mpawu ziphambili zokumelana ne-butt welding zezi:

ubude ukolula, ukuxinana kwangoku welding (okanyewelding yangoku), ixesha welding, uxinzelelo lwe-welding kunye noxinzelelo lwe-forging ephezulu.

b) Ezona parameters ze-flash butt welding zezi:

Inqanaba lokudanyaza: ukulungisa ubude bokwelula, ukugcinwa kweflash, isantya sombane, ukuxinana kwangoku;

Inqanaba eliphezulu lokubunjwa: isibonelelo sokukhanga esiphezulu, isantya esiphezulu sokubumba, uxinzelelo oluphezulu lokubumba, amandla okubamba;

Inqanaba lokufudumala: ukushisa kwangaphambili, ixesha lokufudumala.

Umsebenzi wokwelula ubude kukuqinisekisa isibonelelo esiyimfuneko (welding part shortening) kunye nokulungelelanisa intsimi yobushushu xa ukufudumala ukubaluleka kunye nomsebenzi unokukhethwa ngokuhambelana necandelo le-welding kunye neempawu zezinto eziphathekayo, umkhuba ubonisa ukuba ubude bokwelula akufanele bube ngaphantsi. ngaphezu kwesiqingatha se-diameter ye-welding part, oko kukuthi, l = 0.6 ~ 1.0d (d yi-diameter yeplanga okanye ubude becala lesikwere) ifanelekile. Kwangaxeshanye, xa ukuwelda izinto ezingafaniyo, ukuze kufumaneke ukuhanjiswa kobushushu obulungeleleneyo (ngamanye amaxesha kuqwalaselwe ukuqina kweentsimbi zentsimbi ezingezizo), ezi zimbini kufuneka zisebenzise ubude obuhlukeneyo bokusolula.

I-welding current idlalwa ngokuphindaphindiweyo ngokuxinwa kwangoku, kwaye ukuxinana kwangoku kunye nexesha le-welding zimbini iiparitha eziphambili ezimisela ukufudumeza kwe-welding, kwaye inokulungelelaniswa ngokufanelekileyo komnye nomnye. Ekusebenzeni, kucetyiswa ukuba kugcinwe ubudlelwane obuthile phakathi kobuninzi bobuninzi bangoku kunye nexesha elincinci le-welding, kunye nokusebenzisa ukucaciswa okunzima njengoko i-cross-section iyancipha. Ukuxinana kwangoku kwe-flash butt welding eqhubekayo, izinto zetsimbi ezinombane kunye ne-thermal conductivity, kunye neendawo ezidityanisiweyo ezinecandelo elandisiweyo kufuneka libe phezulu. Ukutshisa i-flash butt welding kunye ne-welds yecandelo elikhulu, ubuninzi bangoku kufuneka bube buphantsi.

Zombini uxinzelelo lwe-welding kunye noxinzelelo oluphezulu lokubumba lunefuthe ekupheliseni ukushisa kwendawo yokudibanisa kunye nokuguqulwa kweplastiki yeendawo ezichaseneyo kunye neendawo ezikufutshane. Isantya esiphezulu sokubumba kunye noxinzelelo lwamandla oluphezulu lunokudityaniswa, kwaye isantya esiphezulu sokubunjwa sinokuncitshiswa ngokufanelekileyo xa isantya esiphezulu sokubumba sikhulu ngokwaneleyo.

IDuphuhlisoPUmbono weButtWelding

Ngophononongo olunzulu lobudlelwane phakathi komgangatho wokumelana ne-welding kunye neeparamitha zenkqubo ye-welding kunye neteknoloji yokukhangela kwi-intanethi, umgangatho we-welding ozinzile unokufumaneka. Ukongeza, izinto ze-welding ziye zandiswa ngakumbi, kwaye uluhlu lwesicelo sokumelana ne-welding lubanzi ngakumbi. Ngenkqubela phambili eqhubekayo yeiteknoloji yokumelana ne-welding, ukumelana ne-welding kuya kuthatha indawo ebaluleke ngakumbi kwimveliso yemveliso yexesha elizayo. Ngokukodwa kwintsimi ye-welding ye-cross-section enkulu kunye neentsimbi ezingafaniyo, i-flash butt welding inethemba lophuhliso oluhle.

Isishwankathelo

Ngophuhliso loshishino lwamandla amatsha, ngakumbi nangakumbi izicelo welding yobhedu kunye noqhagamshelo aluminiyam, ukumelana ukuwelda iteknoloji ihambelana neemfuno zemarike, idityaniswe nenkqubo ukuwelda entsha kunye nobuchwepheshe ulawulo olulungelelanisiweyo, ukumelana ukuwelda kuphuhliso elizayo iya ngenisa i-boom enkulu.

Ixesha lokuposa: Aug-30-2024