Ukuba umtsha ekuchaseni i-welding okanye ujonge ukuqonda okucacileyo kwayo, kuya kufuneka ngokuqinisekileyo ulifunde eli nqaku ngononophelo. Eli nqaku liza kukuthatha ungene nzulu kwihlabathi le-resistance welding. Nokuba ungumqali okanye ujonge ukwandisa ulwazi lwakho, eli nqaku liza kukunika ulwazi oluxabisekileyo.

Yintoni i-Resistance Welding?

I-Resistance welding yindlela yokudibanisa isinyithi esinesantya esiphezulu, esinoqoqosho. Obu buchule bokuwelda bufanelekile kumalungu emilenze, amalunga empundu, okanye adityaniswe angadingi kuxinana komoya, anobunzima obungaphantsi kwe-6mm kwizakhiwo zeshiti elibhityileyo. Ewe kunjalo, iyakwazi ukuwelda iintsimbi ezityebileyo nezikhudlwana, kodwa ukusebenza kwayo iyonke kusenokungabi kuhle njengezinye iindlela zokuwelda.

Inkcazo kunye neZiseko

Ukumelana ne-weldingyindlela apho izixhobo zokusebenza eziza kudityaniswa zibekwe phakathi kwee-electrode ezimbini. Ngokudlula okwangoku kwii-workpieces kunye namanqaku oqhagamshelwano, ukufudumeza ukuchasana kwenzeka, ukuvelisa ubushushu ekudibaneni kwezinto zokusebenza. Oku kufudumeza kwendawo kubangela ukuba indawo inyibilike okanye ibe pliable, ngelixa uxinzelelo oluvela kwii-electrode ezimbini ludibanisa isinyithi kunye.

Xa ikhoyo ngoku ihamba nge-conductor, ivelisa ubushushu ngenxa yokumelana. Ukuphakama kokuchasana xa ikhoyo ngoku isigxina, ubushushu obuninzi buveliswa. Kwinqanaba apho iintsimbi zidibene khona, ukuchasana kukhulu kakhulu kunokuba ngaphakathi kwentsimbi ngokwayo. Ngoko ke, xa umsinga omkhulu udlula kuqhagamshelwano phakathi kwesinyithi kunye ne-electrode, isinyithi sitshisa ngokukhawuleza ngenxa yobushushu obukhulu. Ngeli xesha, isinyithi siba yi-ductile kakhulu, kwaye ngoxinzelelo olusetyenzisiweyo, iziqwenga ezimbini zetsimbi zibophene ngokukhuselekileyo.

Resistance Welding Umgaqo wokuSebenza

Umgaqo we-resistance spot welding kunye nokwakheka kwamalungu kuboniswe kuMzobo 1-1. Isinyithi A kunye nentsimbi B zibekwe phakathi kwee-electrode ezimbini, kwaye uxinzelelo lusetyenziswa kwii-electrodes. Umbane onamandla ugqithiswa phakathi kwee-electrode ezimbini nge-transformer ye-resistance welder. Imiphezulu yoqhagamshelwano yeendawo zokusebenza zenza indawo yokudibanisa ngokomzimba, eyandisa ngokuthe ngcembe njengoko ikhoyo ngoku ishushu. I-deformation yeplastiki kunye nokushisa ngokuqhubekayo kusebenze ii-athomu kwindawo yoqhagamshelwano, ekhokelela ekubunjweni kwesiseko esityhidiweyo. Undoqo otyhidiweyo ukhula ngendlela yeekristale zekholomu, ukutyhala izinto eziphezulu zoxinzelelo lwealloy ukuya komnye. Xa i-electrodes ye-welder isuka kumphezulu wesinyithi, kwaye isinyithi sipholile, i-workpieces idityaniswe kunye, idala ibhondi yentsimbi eyomeleleyo. Umphezulu odibeneyo uyanyamalala, ushiye emva kwe-weld nugget.

1-1

Izinto ezichaphazela i-Resistance Welding

Ukumelana ne-weldingyindlela yokuwelda esebenzisa umsinga wombane ukuvelisa ubushushu ukudibanisa amacandelo esinyithi. Njengoko kukhankanyiwe ngaphambili, umgaqo wokuxhathisa i-welding ngokuyinhloko uvela kumthetho kaJoule wokufudumeza, apho isizukulwana sokushisa kwe-welding ngokuyinhloko sinqunywe yiparameters ezifana nangoku, ukuxhathisa, kunye nexesha le-welding. Inokubonakaliswa ngale fomyula ilandelayo:

Q = I²Rt

Intsingiselo yepharamitha yewelding nganye:

Q - Ubushushu (J)

Mna - Welding current (A)

R — Ukuchasa (Ω)

t - Ixesha lokuwelda (s)

I-Welding yangoku

Ikhoyo ngoku inempembelelo enkulu ekushiseni okwenziwa ngexesha le-welding, njengoko kuboniswe kwifomula. Ixabiso lesikwere sangoku lichaphazela ukushisa, oku kuthetha ukuba ukuphakama kwangoku, ngokukhawuleza ukushisa kuya kwanda. Ke ngoko, xa uhlengahlengisa iiparitha ze-welding ngaphambi kwe-welding, kubalulekile ukuseta umsinga ofanelekileyo. Ukuba i-welding current incinci kakhulu, i-weld ayiyi kunyibilika, kwaye akukho ngundoqo we-fusion uya kwenza. Ukuba i-current inkulu kakhulu, i-fusion core iya kukhula ngokukhawuleza, ibangele ukutshiza ngokugqithiseleyo ngexesha le-welding kunye nokonakalisa i-electrodes.

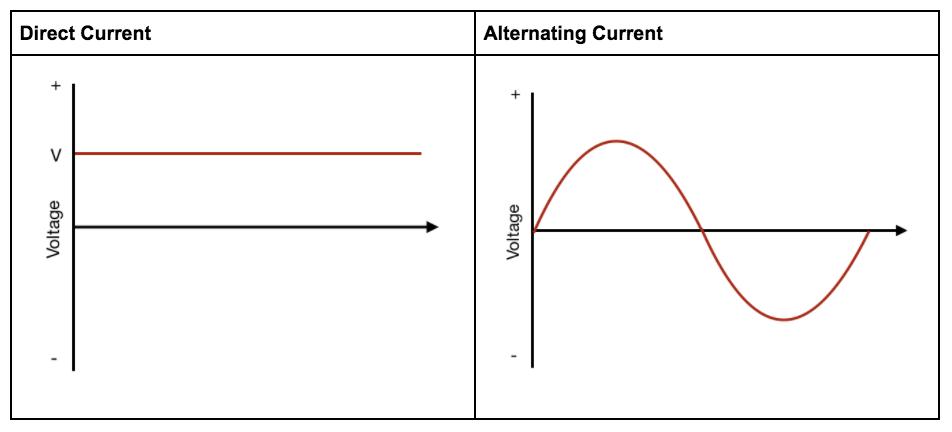

I-Welding yangoku ihlulwe kakhulu ibe yi-alternating current (AC) kunye ne-direct current (DC), njengoko kuboniswe kumzobo ongezantsi. Ioomatshini bokuwelda amabalasisebenzisa nazo zahlulwe koomatshini bokuwelda bangoku ngokuthe ngqo kunye nokutshintshana koomatshini bokuwelda bangoku. Oomatshini bokuwelda bangoku ngokuthe ngqo basebenzisa isigaba sesithathu sonikezelo lwamandla, ukuqinisekisa ukuhanjiswa kwamandla okulinganayo, kwaye banokufikelela kwi-welding frequencies ezingaphezu kwe-1000 Hz, okukhokelela ekuchanekeni kwe-welding ephezulu. Bakwanayo nenzuzo yemfuno ephantsi yamandla ukusuka kwigridi yamandla, okwenza ezi welders zonga amandla zithandwa kakhulu phakathi kwabavelisi beshishini lokuvelisa. Ukutshintshana koomatshini bokuwelda bangoku banesigaba esinye semveliso ye-50Hz, umthamo ophezulu oqhubekayo womthwalo, kunye neemfuno eziphezulu zegridi yamandla. Ukongeza, banamandla okuwelda aphantsi, afuna amaxesha amade welding.

Qhagamshelana Ukumelana

Ukusuka kwifomula, kulula ukubona ukuba ukuxhathisa kuhambelana ngokuthe ngqo nobushushu obuveliswayo. Ukuphakama kokumelana, ubukhulu bobushushu obuveliswayo ngexesha le-welding. Ukuchasana kusasazwa kwiindawo ezahlukeneyo ze-electrode kunye ne-workpiece. Ngexesha le-welding, ukuchasana okuphezulu kwenzeka kwindawo yoqhagamshelwano ye-workpiece, okukhokelela kwisizukulwana esiphezulu sokushisa. Okulandelayo ukuchasana kwindawo yoqhagamshelwano phakathi kwe-workpiece kunye ne-electrode. Nangona kunjalo, ekubeni i-electrode ipholile ngamanzi kwaye ipholile ngokukhawuleza, ubushushu buyancipha ngokukhawuleza. Ngakolunye uhlangothi, ukuchasana koqhagamshelwano phakathi kwee-workpieces, nangona kuyanyamalala, kunokutshatyalaliswa kokushisa okungahambi kakuhle, okukhokelela kumaqondo aphezulu. Ke ngoko, indawo encinci kuphela phakathi kwezixhobo zokusebenza inokufikelela kubushushu obuyimfuneko ukwenza i-fusion core kunye ne-weld kunye.

Ukongezelela, ubushushu kunye noxinzelelo lwe-electrode luchaphazela ukuchasana. Njengoko iqondo lokushisa liphakama, amandla okuvelisa isinyithi ayancipha, ukwandisa indawo yoqhagamshelwano phakathi kwezinto zokusebenza kunye naphakathi kwendawo yokusebenza kunye ne-electrode, okubangela ukunyanzeliswa kwehle. Ukwandisa uxinzelelo lwe-electrode kwenza ukuba indawo yokusebenza ibe lula, ikhulise indawo yoqhagamshelwano kunye nokunciphisa ukuxhathisa. Ngenxa yoko, kukho isenzeko apho, ngexesha lokuwelda kwezixhobo eziqhelekileyo, ukuchasana kuyanda kamsinya emva kokukhanyisa, kwaye xa amandla ecinyiwe kunye neefom ze-fusion core, ukuchasana kuqala ukuncipha.

Ixesha le-Welding

Okukhona ixesha lokuwelda lide, kokukhona ubushushu buveliswa phezulu. Kule fomyula, okwangoku kunye nexesha zinokuncedisana. Xa ufuna i-weld eyomeleleyo, unokuseta umsinga ophezulu ixesha elifutshane ukuvelisa ubushushu ngokukhawuleza kwaye wenze i-fusion core ukugqiba i-welding. Kungenjalo, unokuseta umsinga ophantsi ixesha elide, kodwa kukho umda kule ndlela. Ukuba ixesha libekwe ixesha elide, kunokukhokelela ekutshizeni okugqithisileyo kwaye kunokubangela ukuba i-electrode ibambelele. Nokuba yeyangoku okanye lixesha, kukho imida. Xa ubeka iiparitha, kufuneka uqwalasele izinto kunye nobukhulu bomsebenzi, kunye namandla omatshini we-welding.

Iipropati zeMathiriyeli

Izinto eziphathekayo ze-workpiece zichaphazela kakhulu ukumelana kwayo, okudlala indima ebalulekileyo ekuveliseni ukushisa kwe-welding. Xa welding steel stainless, ene-resistivity ephezulu kunye nokungahambi kakuhle kwe-thermal, kulula ukuvelisa ubushushu kodwa kunzima ukubuchitha, ngoko ke imisinga emincinci iyafuneka. Xa ukuwelda iialloyi ze-aluminiyam kunye ne-resistivity ephantsi kunye ne-thermal conductivity enhle, kunzima ukuvelisa ubushushu kodwa kulula ukubuchitha, ngoko ke imisinga emikhulu iyafuneka. Iintsimbi ezifana nesilivere kunye nobhedu zine-conductivity ephezulu ye-thermal kunye ne-resistivity ephantsi, ngoko ke kunye nemisinga ephezulu, ayenzi bushushu obuninzi kodwa inokubuhambisa kude. Ke ngoko, ezi zinyithi azifanelekanga kwi-welding yokumelana kodwa zinokusetyenziswa njengezinto ze-electrode.

Uyilo lwe-Electrode kunye neJometri

Ubume kunye nezinto eziphathekayo ze-electrode nazo zichaphazela ukuveliswa kobushushu. Indawo yoqhagamshelwano phakathi kwe-electrode kunye ne-workpiece ichaphazela ubuninzi bangoku. Ukusetyenziswa rhoqo kwee-electrodes kunokukhokelela ekunxibeni kunye nokuguqulwa, ukwandisa indawo yoqhagamshelwano kunye nokunciphisa amandla e-welding. Ngoko ke, kufuneka silungise kwaye sitshintshe iingcebiso ze-electrode ngokukhawuleza. I-conductivity ye-thermal kunye nokuchasana kwe-electrode kuchaphazela ukuhanjiswa kobushushu. Ngoko ke, kufuneka sikhethe izinto eziphathekayo ezine-conductivity efanelekileyo ye-thermal kunye nokuchasana okuphantsi.

Ukulungiswa komphezulu

Ubume kunye nezinto eziphathekayo ze-electrodes nazo zichaphazela ukuveliswa kobushushu. Indawo yoqhagamshelwano phakathi kwe-electrode kunye ne-workpiece ichaphazela ubuninzi bangoku. Xa i-electrodes yethu isetyenziswa rhoqo kwaye igugile, yongeza indawo yoqhagamshelwano, ekhokelela ekunciphiseni amandla e-welding. Ngoko ke, kufuneka silungise kwaye sitshintshe iingcebiso ze-electrode ngokukhawuleza. I-conductivity ye-thermal kunye ne-resistiveivity ye-electrodes ichaphazela ukuhanjiswa kobushushu. Ngoko ke, kufuneka sikhethe izinto eziphathekayo ezine-conductivity efanelekileyo ye-thermal kunye ne-resistivity ephantsi.

Iintlobo zeResiukuma Welding

Ngenxa yokucaciswa kwemveliso eyahlukeneyo kunye neemfuno ze-welding, iinkqubo ezahlukeneyo zokumelana ne-welding zisetyenziselwa ukugqiba umsebenzi. I-Resistance welding inokwahlulwa ibe yi-welding spot, i-welding ye-projection, i-seam welding, kunye ne-butt welding ngokusekelwe kwinkqubo ye-welding.

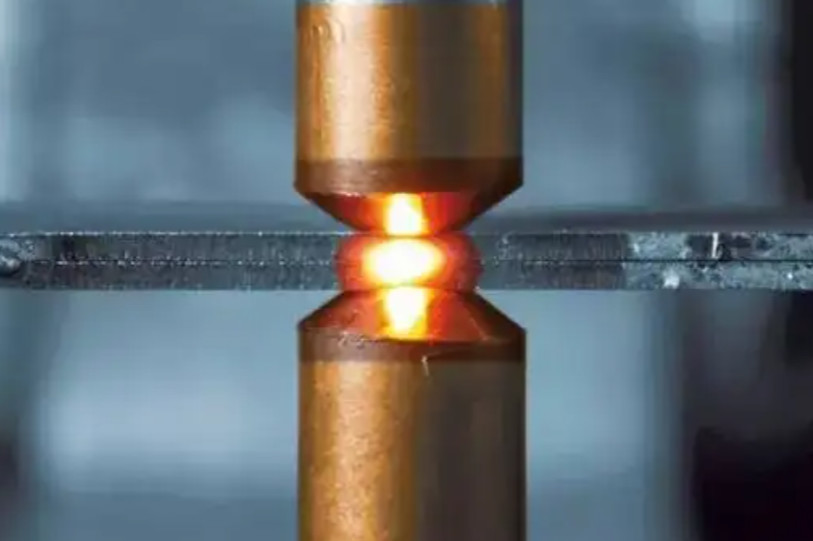

Spot Welding

Ukuwelda indawoyindlela yokuwelda apho isinyithi sicinezelwa kunye nge-electrode ephezulu nasezantsi kwaye idityaniswe ngokudlula okwangoku kuyo. Yindlela yemveli yokumelana nokuwelda, kulula ukuyisebenzisa, kwaye ifuna amanqanaba ezakhono asezantsi kubasebenzi. Ngenxa yenkqubo yokuwelda ekhethekileyo, ukuwelda yeyona nto iphambili yokhetho lwentsimbi kubunjineli be-aerospace kwaye isetyenziswa ngokubanzi kumzimba wemoto kunye namanye amacandelo. Idla ngokusetyenziselwa ukuwelda amashiti abhityileyo entsimbi ephantsi yekhabhoni, ialuminiyam, intsimbi engatyiwa, intsimbi ekhandiweyo, kunye nezinye iipleyiti ezibhityileyo, ezijikeleze i-3 millimeters ubukhulu.

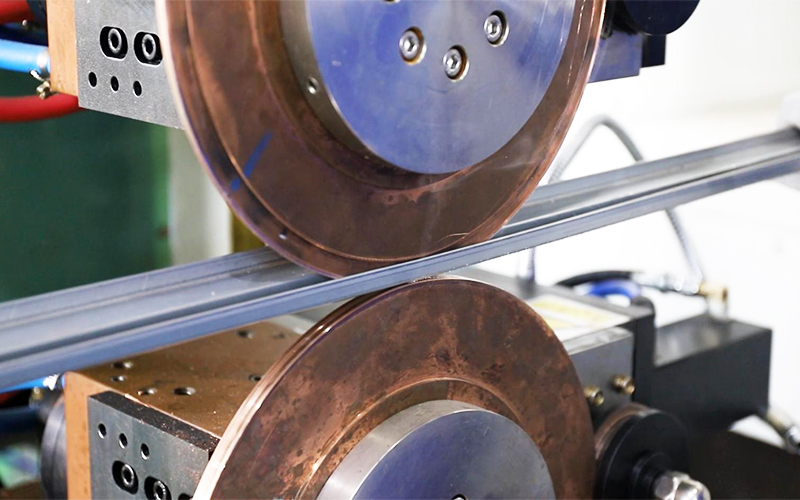

Ukuwelda komthungo

Ukuwelda komthungoNgokwesiqhelo kubandakanya ukudibanisa imiphetho yamacandelo esinyithi amabini. Izixhobo zokusebenza ezimbini zetsimbi zibekwe phakathi kwee-electrode ezimbini ze-roller. Ngelixa i-electrode enye iqengqeleka kwaye ifaka uxinzelelo, ukukhutshwa okuqhubekayo okanye okuphakathi kwenzeka. Ubushushu obuveliswe kwindawo yokuqengqeleka ye-electrode bunyibilikisa ii-workpieces kwaye zidibaniswe kunye, zenze i-weld seam eqhubekayo. Le ndlela isetyenziswa ngokubanzi ukuwelda iinxalenye zetsimbi ezifuna amajoyina atywiniweyo. Ekubeni indawo ye-welding inde, ukuthintela ukungahambi kakuhle, ngokuqhelekileyo sisebenzisa i-welding yendawo yokubeka phambi kwe-seam welding.

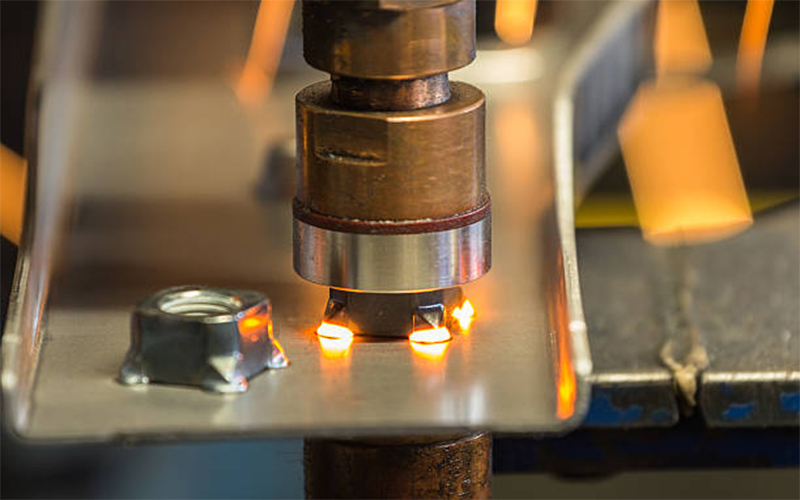

Uqikelelo lweWelding

Uqikelelo weldinglulwahlulo lwe-welding yendawo, apho ukubunjwa kwendawo ye-weld kufana ne-welding, kodwa i-welding ye-projection idla ngokusetyenziswa kwi-workpieces eneendawo eziphakanyisiweyo. Ubukho bala manqaku aphakanyisiweyo kunciphisa indawo apho i-current idlula khona, ukwandisa ukuxinwa kwangoku kwindawo ye-welding. Oku kufudumeza okugxininisiweyo kuququzelela uxhulumaniso lokudibanisa. Le ndlela ye-welding yaziwa ngokuba yi-projection welding. I-welding ye-Projectioning inokwenza enye okanye ngaphezulu kwe-fusion cores kwi-joint kanye. Ngexesha le-welding, okwangoku okufunekayo kwi-welding ye-projectional kwindawo efanayo ye-weld ingaphantsi kwaleyo ye-spot welding. Nangona kunjalo, ngaphambi kokuba uqikelelo ngalunye lutyunyuzwe, okwangoku kufuneka kunyibilike uqikelelo; kungenjalo, kusenokubakho isixa esibalulekileyo sokutshiza. Iprojection welding ingasetyenziselwa ukuwelda amandongomane, iibholiti, okanye iipleyiti ezinamanqaku anyusiweyo kwaye isetyenziswa ngokubanzi ekwenzeni izinto ze-elektroniki kunye neemoto.

Ukuwelda ngeempundu

Ukuwelda ngeempunduibandakanya ukulungelelanisa ubuso besiphelo sezinto ezimbini zokusebenza zetsimbi, ukuzibeka phakathi kwe-electrode, ukuqinisa ngokukhuselekileyo izixhobo zokusebenza ezimbini, kunye nokusebenzisa umbane ophezulu ukuvelisa ubushushu, ukunyibilikisa umphezulu wokudibanisa wezinto zokusebenza kunye nokuzidibanisa. I-butt welding iphinda yohlulwe ibe yi-flash butt welding kunye ne-resistance butt welding.

I-flash butt welding yinkqubo ye-welding ekhawulezayo esebenzisa i-high current ukunyibilikisa ngokukhawuleza i-workpieces, ifake uxinzelelo ukwenza udibaniso lwesigaba esiqinileyo. Iqhele ukusetyenziselwa ukuwelda iindawo ezinkulu ezinqamlezileyo zentsimbi, amashiti, kunye nemibhobho, eneendawo eziphezulu ezifikelela kwi-20,000mm² nangaphezulu. Ngethuba lenkqubo yokukhupha i-welding, iintlantsi ziveliswa kwindawo yoqhagamshelwano, ngoko ke igama elithi flash butt welding. Iyakwazi ukuwelda intsimbi yekhabhoni ephezulu, intsimbi engatyiwayo, ialloys aluminiyam, kwaye ikwazi ukuwelda iintsimbi ezifanayo ezifana nobhedu kunye nealuminium.

I-Resistance butt welding isebenzisa ubushushu obuxhathisayo ukuzisa amalungu e-workpiece kwindawo yeplastiki kumaqondo obushushu aphezulu, igqibezela inkqubo yokuwelda ngamandla okubumba. Ilungele ukuwelda iindawo ezinqamlezileyo ngaphakathi kwe-250mm², ehlala isetyenziselwa ukuwelda iingcingo zentsimbi ezinqamlezileyo ezincinci, iintonga kunye nemicu.

Ukubaluleka kweMveliso

- Ukumelana ne-welding ayifuni ukongezwa kwesinyithi ngexesha lenkqubo ye-welding, okubangelwa ukusebenza kakuhle kwe-welding kunye nokungcola okuncinci.

- Ngenxa yokungaguquguquki kunye nozinzo, ukuxhathisa i-welding kulula ukuzenzela, ukudibanisa ngaphandle komthungo kunye ne-automation ukuqhubela phambili ukuqhubela phambili ukusebenza kwemveliso kunye nokugcina abasebenzi.

- Xa kuthelekiswa nezinye iindlela ze-welding, i-resistance welding yindleko-esebenzayo. Okokuqala, iindleko zezixhobo zokumelana ne-welding ziphantsi, kwaye okwesibini, kukho inkunkuma yezinto ezincinci ngexesha lenkqubo yokumelana ne-welding. Oku kunciphisa kakhulu iindleko zemveliso kubavelisi kwishishini lemveliso.

- I-Resistance welding isetyenziswa ngokubanzi kuwo wonke amashishini ahlukeneyo kwaye ibaluleke kakhulu kumacandelo afana ne-aerospace, ukuveliswa kweemoto, kunye nokunye.

- I-Resistance welding ifanelekile ukuwelda iintlobo ezahlukeneyo zesinyithi kwishishini lokuvelisa, kubandakanywa intsimbi engatyiwa, intsimbi ye-carbon, i-aluminiyam, ubhedu, kunye nokunye, okwenza kube yinto eguquguqukayo kwisicelo sayo.

Usetyenziso

I-Resistance welding isetyenziswa ngokubanzi, ngakumbi kumashishini afana nezixhobo zemoto, i-aerospace, i-electronics, kunye neshishini elinzima. Njengoko imfuno yamacandelo entsimbi edityanisiweyo kumashishini ahlukeneyo iyaqhubeka nokukhula, imigangatho ephezulu yetekhnoloji ye-welding iye yamiselwa, iqhuba inkqubela phambili kunye nophuhliso lokuxhathisa ukuwelda.

Izicelo zoShishino lweemoto

Kwimveliso yemoto, apho ukhuseleko kunye nokuzinza kubaluleke kakhulu, ukuxhathisa i-welding yindlela esetyenziswa ngokuqhelekileyo. Ihlala isetyenziselwa ukudibanisa izinto ezahlukeneyo zentsimbi kwimizimba yemoto, njengophahla, iingcango, amashiti esinyithi, kunye namandongomane esinyithi. I-Resistance welding inika ukusebenza kakuhle okuphezulu, umgangatho we-welding ozinzile, kwaye i-automated ngokulula, iyenza ibe yinkqubo eyimfuneko kwishishini lokuvelisa iimoto.

Aerospace Industry Applications

I-Resistance welding isetyenziswa rhoqo ukudibanisa izinto zentsimbi kwinqwelomoya kunye neerokethi, ezinjengokudibanisa amaphiko eenqwelomoya kunye neefuselages, kunye neendawo ezahlukeneyo zentsimbi ezincinci. La malungu kufuneka abe namandla aphezulu kunye nokuqina, kunye neemfuno ezingqongqo kumgangatho wamalungu, kulapho ukuwelda kugqwesa khona. I-resistance welding idlala indima ebalulekileyo kwishishini le-aerospace, kwaye ukuqhubela phambili kulo mmandla kukwaququzelelwa licandelo le-aerospace.

Izicelo zoShishino loMbane

I-Resistor welding isetyenziswa ngokuqhelekileyo kumacandelo e-elektroniki kunye neenxalenye ezithile zetsimbi kwizixhobo zombane. Inika ukuchaneka okuphezulu kwe-welding kwaye ifanelekile ukudibanisa izinto ezincinci ezifana neetshiphu ze-elektroniki kunye neengcingo. Kwixesha lanamhlanje elivela ngokukhawuleza lezixhobo zombane, i-resistor welding ikhawulezisa ukuhlanganiswa kwezinto zombane, ukuqhuba ukuqhubela phambili kweshishini.

Izicelo zoShishino olunzima

I-resistance welding isoloko isetyenziselwa ukuwelda amacandelo amakhulu esinyithi kwiibhulorho kunye nezakhiwo, ezinje ngeeflange ezisezantsi zebhulorho kunye nokuqiniswa kwentsimbi. Ikwasetyenziswa ekwenzeni oomatshini abakhulu bokudibanisa iindawo zentsimbi. Ngobuchule bayo be-welding obusebenzayo kunye nozinzile, ukuwelda ukuxhathisa kuye kwaba yenye yeendlela eziphambili zokucubungula kwishishini elinzima. Iqinisekisa ukhuseleko lwezixhobo ezinzima kunye nezakhiwo.

Izixhobo kunye nezixhobo

Oomatshini bokuwelda

Ukuxhathisa oomatshini bokuweldabohlulwe ngokweendidi ezine eziphambili: oomatshini bokuwelda, oomatshini bokuwelda, oomatshini bokuwelda umthungo, kunye noomatshini bokuwelda ngeempundu, ngokusekelwe kwiinkqubo ezahlukeneyo. Khetha izixhobo ezifanelekileyo ze-welding ngokweempawu zezinto kunye nemilo.

Ii-electrodes

Ii-electrodeyinxalenye ebalulekileyo yokuqinisekisa umgangatho we-welding. Izinto eziphambili ze-electrode ze-welding zezi: i-chromium zirconium yobhedu, i-aluminium oxide yobhedu, i-beryllium cobalt yobhedu, i-tungsten, i-molybdenum, i-graphite, njl. Ngokuxhomekeke kwimisebenzi eyahlukeneyo edityanisiweyo, i-electrodes yahlulahlulwe ibe yi-electrode tyaba, i-electrodes engqukuva, i-electrode nut, ibholt i-electrodes, njl. Ngokuqhelekileyo, ukulungiswa kwe-electrode kubandakanya ukufakwa kwe-tapered, nge i-taper ratios ikakhulu kwi-1:10 kunye ne-1:5.

Iinkqubo zokupholisa

Ngexesha lokusebenza, oomatshini be-welding yokumelana bafuna amanzi ajikelezayo ukupholisa amacandelo afana ne-electrode kunye ne-transformers. Ngoko ke, sifaka inkqubo yokupholisa koomatshini bokumelana ne-welding. Ubushushu bamanzi okupholisa kufuneka bube ngaphantsi kwe 30°C. Ukuba iqondo lokushisa liphezulu kakhulu, linokubangela ukuvalwa kokukhusela umatshini we-welding. Kungcono ukusebenzisa amanzi okupholisa angenakungcola ukujikeleza ukuthintela amabala amanzi kunye nokuvaleka kwemibhobho.

Indlela yokukhetha iNkqubo yeWelding eLungileyo?

Ukukhethwa kwendlela ye-welding kuxhomekeke kwizinto ezininzi.

Ukutyeba kunye neMilo ye-Workpiece: Eyahlukileyoiindlela ze-weldingzilungele ii-workpieces ezinobunzima obahlukeneyo kunye neemilo. Umzekelo, ukuwelda ukuxhathisa kulungele kuphela ukuwelda amashiti esinyithi acekethekileyo, ngelixa izinto ezibunjwe ngendlela engaqhelekanga kunye nezityebileyo zihlala zidityaniswa kusetyenziswa i-arc welding.

Iimfuno zoMgangatho we-Welding: Umgangatho ofunwayo we-welding uphinda uchaze ukhetho lwendlela ye-welding. Kwizixhobo zokusebenza ezifuna ukutywinwa okuphezulu kunye namandla adibeneyo, iindlela ze-welding ezihlangabezana nezi mfuno kufuneka zikhethwe.

Ukuphumelela kweMveliso kunye neNdleko: Ukuba umthamo wemveliso wonyaka ophezulu ufunekayo, ukukhetha indlela ye-welding kunye nokusebenza okuphezulu kuyimfuneko. Ukuqwalaselwa kweendleko nako kufuneka kuthathelwe ingqalelo.

Imiba yokusingqongileyo: Ezinye iindlela zokuwelda zivelisa inkunkuma nezinto ezikhutshwayo, nto leyo ebangela ukungcoliseka kwendalo. Ngoko ke, ukuqwalaselwa kokusingqongileyo kufuneka kuthathelwe ingqalelo xa ukhetha indlela ye-welding.

FAQ:

Yeyiphi imida yokumelana ne-welding?

I-resistance welding ayifanelekanga ukudibanisa izinto ezinkulu zetsimbi.

Uqinisekisa njani ukhuseleko kwi-resistance welding?

Xa usebenzisa i-welding resistance, nxiba isigcina-ntloko sokhuseleko kunye nezibuko zokhuseleko.

Ndingaqeqeshelwa njani ukuwelda?

Ungafumana uqeqesho kwi aukuxhathisa umenzi welding.

Ziziphi iingxaki ezingundoqo zomgangatho wokuxhathisa i-welding joints?

I-cold solder joint, amandla angonelanga, i-welding deformation, i-oxidation.

Iindlela zokuhlola ukuxhathisa i-welding joints

Uvavanyo olutshabalalisayo, uvavanyo lwe-microscopic, ukuhlolwa okubonakalayo, uvavanyo lwe-metallographic, uvavanyo lwe-ultrasonic.

Ixesha lokuposa: Apr-02-2024