I-welding ye-Seam yinkqubo enzima ye-welding.Eli nqaku liphonononga ukuntsonkotha kwe-welding ye-seam, ukusuka kwimigaqo yayo yokusebenza ukuya kwizicelo zayo, iingenelo kunye nemingeni. Nokuba umtsha ekudibaniseni okanye ujonge ukwenza nzulu ukuqonda kwakho kobu buchule bubalulekileyo boshishino, esi sikhokelo siya kunika ulwazi oluxabisekileyo malunga nendlela i-seam welding esebenza ngayo nalapho isetyenziswa rhoqo.

Intshayelelo ye-Seam Welding

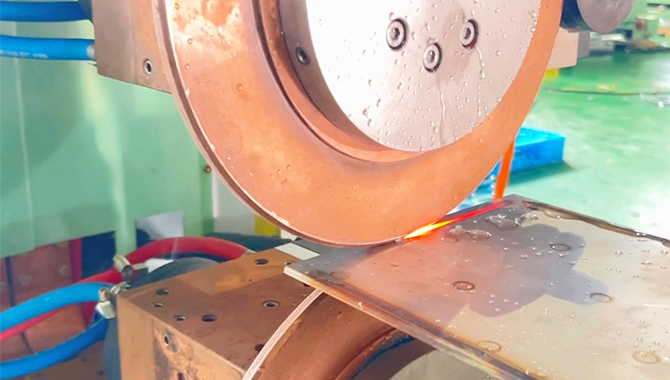

Umthungo welding luhlobo olukhethekileyoinkqubo yokumelana weldingapho amaqhekeza amabini nangaphezulu esinyithi adityaniswa kunye ecaleni komthungo oqhubekayo okanye uthotho lweendawo zokuwelda eziwelanayo. Isetyenziswa kakhulu kumashishini afuna ukudityaniswa komoya okanye ukungangeni manzi, njengeemoto, i-aerospace, kunye necandelo lemveliso. Ngokungafaniyo neendawo zokuwelda zemveli, ezidala iingongoma ze-weld zomntu ngamnye, ukuwelda komthungo kuvelisa i-weld eqhubekayo, eyomeleleyo ngokusebenzisa i-electrode ejikelezayo ehamba ecaleni kwendibaniselwano, idibanisa izinto kunye.

Indlela i-Welding ye-Seam isebenza ngayo

I-welding ye-Seam isebenza kumgaqo ofanayo osisiseko njenge-resistance welding:ukumelana nombane kusetyenziselwa ukuvelisa ubushushu, obunyibilikisa izinto ezidityanisiweyo kunye. Nangona kunjalo, i-welding ye-seam iyahlula ngendlela i-weld esetyenziswa ngayo ngokuqhubekayo kunye nobude be-workpiece. Apha ngezantsi kukucazululwa kwamacandelo angundoqo kunye nendlela inkqubo esebenza ngayo.

Ii-Electrodes eziJikelezayo:Intliziyo yenkqubo ye-welding ye-seam kukusetyenziswa kwe-cylindrical, i-electrode ejikelezayo, ngokuqhelekileyo yenziwe ngobhedu okanye ezinye izinto zokuqhuba. Ezi electrode zicinezela iziqwenga zentsimbi, zibonelela ngamandla ombane akhoyo kunye noomatshini abafunekayo ukwenza i-weld. Njengoko ii-electrodes zijikeleza, zihamba kunye nobude bomdibaniso, zisebenzisa uxinzelelo kunye nokuqhubekayo ngokuqhubekayo.

Usetyenziso lwangoku:Umbane wombane ugqithiswa kwi-electrodes, udala ukuchasana kwindawo apho iziqwenga ezimbini zetsimbi zithinta. Ukumelana kuvelisa ubushushu, kubangela ukuba iintsimbi zinyibilike kwaye zidibanise kunye. Kwi-welding ye-seam, lo mjelo usetyenziswa ngendlela ye-pulsed okanye eqhubekayo, kuxhomekeke kuhlobo oluthile lwe-welding (kuxoxwa ngakumbi ngezantsi).

Uxinzelelo kunye nokupholisa:Njengoko ukuhamba kwangoku, ii-electrode ezijikelezayo zisebenzisa uxinzelelo oluqhubekayo kwi-workpiece, iqinisekisa ukuba izinto ezityhidiweyo ziqina zibe yi-weld eqinile, eqhubekayo. I-electrodes iphinda isebenze njengendlela yokupholisa, inceda ekulawuleni ubushushu kunye nokuthintela ukufudumala, okungonakalisa i-weld okanye izinto ezijikelezayo.

Intshukumo eqhubekayo:Isenzo esijikelezayo se-electrode yinto eyenza i-welding ye-seam ihluke kwezinye iindlela zokumelana ne-welding. I-electrodes ihamba kunye nomgca odibeneyo ngesantya esilawulwayo, ukuqinisekisa ukuba ukushisa kusetyenziswe ngokulinganayo kuwo wonke ubude bomthungo. I-weld enesiphumo yomelele, ayiguquguquki, kwaye ihlala iqinile emoyeni okanye iqinile.

Iintlobo ze-Seam Welding

I-welding ye-Seam ingahlelwa kwiindidi ezimbini eziphambili ngokusekelwe kwindlela esetyenziswa ngayo langoku:

Ukuwelda ngokuqhubekayo kwe-Seam

Kule ndlela, umbane oqhubekayo usetyenziswa ngelixa i-electrodes ihamba kunye nomdibaniso. Oku kubangela i-weld eqhubekayo efana ne-bead. Ukuwelda ngokuqhubekayo kwe-seam kudla ngokusetyenziswa xa isitywina esingangeni moya okanye esingangeni manzi sifuneka, njengakumatanki okanye kwimibhobho yepetroli.

Ukuwelda komthungo okwethutyana

Ikwabizwa ngokuba yi-roll spot welding, le ndlela isebenzisa umsinga wombane kwi-pulses ngelixa i-electrode ihamba. Isiphumo luludwe lweendawo ezidityanisiweyo zokuwelda ezenza i-seam. Olu hlobo lwe-welding ye-seam luhlala lusetyenziswa xa ukunyaniseka kwesakhiwo kubaluleke ngaphezu kokungena moya, njengakwizicelo ezithile zeemoto.

Izixhobo ezifanelekileyo kwi-Seam Welding

Umatshini wokuwelda umthungoisebenza ngokukodwa kwiintsimbi eziqhuba kakuhle umbane kwaye zinendawo esezantsi yokunyibilika. Izinto eziqhelekileyo ziquka:

Intsimbi:Zombini iintsimbi eziphantsi kwekhabhoni kunye nezingatyiwa sisonka zihlala zithungelwa kwizixhobo zemoto nakwimizi-mveliso.

Aluminiyam:Ngelixa ingumceli mngeni ngakumbi ngenxa yomgangatho ophezulu wokuqhuba, ialuminiyam idla ngokudityaniswa ne-aerospace kunye nemveliso.

Iialloyi zobhedu:Ubhedu'I-conductivity egqwesileyo iyenza ilungele ukusetyenziswa kumacandelo afuna ukusebenza kakuhle kwe-thermal kunye nombane, njengeeradiyetha kunye neendawo ezivaliweyo zombane.

Usetyenziso lwe-Seam Welding

I-welding ye-Seam isetyenziswa ngokubanzi kumashishini afuna amandla aphezulu, angangeni moya, okanye adibeneyo angamanzi. Ngezantsi zezinye zezona nkqubo zixhaphakileyo:

Umzi mveliso weemoto:Ukuwelda komthungo kudla ngokusetyenziswa kwimveliso yezinto zemoto ezinje ngeetanki zamafutha, iimufflers, kunye neerimu zamavili. I-weld eqhubekayo iqinisekisa ukuba ezi nxalenye zingenamoya kwaye zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala khona.

I-Aerospace:Ishishini le-aerospace lihlala lifuna izinto ezikhaphukhaphu kodwa ezomeleleyo, kwaye i-seam welding isetyenziselwa ukudibanisa amashiti amancinci e-aluminiyam kunye nentsimbi. Kule ntsimi, imfuno ethembekileyo, engenamoya, kunye namanzi adibeneyo ibaluleke kakhulu kwiinkqubo zepetroli kunye nezakhiwo.

Ukwenziwa kweeTanki kunye neMigqomo:I-Seam welding isetyenziselwa kakhulu ukwenza iitanki zamafutha, iitanki zamanzi, kunye nezikhongozeli zeekhemikhali ekufuneka zivaliwe ngokupheleleyo ukuthintela ukuvuza. Umgca we-weld oqhubekayo uqinisekisa ukunyaniseka kwetanki, okwenza kube lula ukubamba ulwelo okanye iigesi phantsi koxinzelelo.

Imibhobho yesinyithi kunye neMibhobho:Ukuwelda komthungo kusetyenziselwa ukwenza imibhobho yentsimbi kunye neetyhubhu kumashishini ahlukeneyo, kubandakanya ioyile negesi, imibhobho yamanzi kunye nokwakha. Indlela iqinisekisa i-seam eqhubekayo, evuzayo enokumelana noxinzelelo lwangaphakathi.

Ukupakishwa kokutya kunye nesiselo:Kwishishini lokupakisha, ukuwelda komthungo kusetyenziswa ukwenza iinkonkxa zentsimbi, izikhongozeli kunye neziciko. Ukuchaneka kunye nesantya se-seam welding kwenza kube lukhetho olufanelekileyo kwimveliso enkulu, ukuqinisekisa ukuba iimveliso zitywinwe ngokukhuselekileyo kwaye zihlala zinyumba.

Amacandelo oMbane:Ukuwelda komthungo kukwasetyenziselwa ukwenza izinto ezinje ngeeradiyetha, izinto zokufudumeza, kunye nezibiyelo zombane. Umthungo oqhubekayo uqinisekisa ukuqhubeka kombane kunye nokunyaniseka kwesakhiwo.

Izinto eziluncedo kwi-Seam Welding

I-welding ye-Seam ibonelela ngeenzuzo ezininzi ngaphezu kwezinye iindlela zokuwelda, iyenza ibe lukhetho oludumileyo kumashishini afuna ukuqina, amakhonkco akumgangatho ophezulu. Nazi ezinye zeenzuzo eziphambili:

Isantya kunye nokusebenza ngokufanelekileyo: I-welding ye-Seam iphumelele kakhulu, ngakumbi kwiindawo eziqhubekayo zemveliso. Inkqubo ezenzekelayo ivumela i-welding ekhawulezayo kunye nobude bonke bomthungo, ukunciphisa ixesha lokuvelisa.

I-Welds eqinile, ehambelanayo: Ubume obuqhubekayo be-welding ye-seam iqinisekisa ukuba i-weld ifana nayo yonke i-joint, okubangelwa uxhulumaniso olunamandla, oluthembekileyo. Oku kuhambelana kunciphisa umngcipheko weziphene ezifana neentanda okanye iindawo ezibuthathaka.

Amatywina angangeni moya kunye naManzi: I-welding ye-Seam ilungele ukusetyenziswa apho i-joint kufuneka itywinwe ngokupheleleyo, njengamatanki, imibhobho, kunye nezikhongozeli. I-weld eqhubekayo iqinisekisa ukuba akukho zithuba apho umoya okanye ulwelo unokudlula khona.

Ukuphazamiseka okuncinci: Ngenxa yokuba ukushisa kwe-welding kusendaweni kwaye i-electrodes ibonelela ngokupholisa okuqhubekayo, i-seam welding ivelisa ukuphazamiseka okuncinci kwizinto ezijikelezayo. Oku kubaluleke ngakumbi xa usebenza ngeentsimbi ezibhityileyo ezithanda ukulwa.

I-Automation-Friendly: Iinkqubo ze-welding ze-Seam zihambelana kakhulu kunye ne-automation, zizenza zilungele indawo yokuvelisa enkulu. Oomatshini bokudibanisa i-seam abazenzekelayo banokuvelisa iziphumo ezihambelanayo kunye nokungenelela okuncinci komntu, ukunciphisa iindleko zabasebenzi kunye nokunyusa imveliso.

Imingeni kunye neMida ye-Seam Welding

Ngelixa i-welding ye-seam ineenzuzo ezininzi, ikwabonelela ngemingeni kunye nemida:

Iindleko eziphezulu zesiXhobo:Izixhobo ezikhethekileyo ezifunekayo ukuwelda i-seam, ngakumbi kwi-seam welding eqhubekayo, zinokubiza. Oku kwenza ukuba kufikeleleke kancinci kwiindibano zocweyo ezincinci okanye iinkampani ezinohlahlo lwabiwo-mali olulinganiselweyo.

Unyino lwezinto eziphathekayo:Ukuwelda komthungo kusebenza ngcono kwiintsimbi eziqhubayo njengentsimbi kunye ne-aluminiyam. Izinto ezinokuthi ziqhube kakuhle okanye zingabikho ukushisa, ezifana neeplastiki ezithile okanye i-ceramics, azikwazi ukuthungwa ngokusebenzisa le ndlela.

Unyino lokutyeba:Ukuwelda komthungo kusebenza kakhulu kwizinto ezibhityileyo, ngokuqhelekileyo ngaphantsi kwe-3mm ngobukhulu. Kwizinto ezityebileyo, ezinye iindlela zokuwelda, ezifana ne-MIG okanye i-TIG welding, zinokufaneleka ngakumbi.

I-Electrode Wear:Ukujikeleza rhoqo kunye noxinzelelo lwee-electrode kunokukhokelela ekunxibeni kwexesha, ngakumbi xa izinto zokuwelda njengentsimbi enokubangela ukuthotywa kwe-electrode. Ukugcinwa rhoqo kunye nokutshintshwa kwee-electrodes kuyimfuneko ukuqinisekisa ukusebenza okuhambelanayo.

Ukuqukumbela

I-welding ye-Seam yinkqubo ebalulekileyo kwimveliso yanamhlanje, enikezela ngendlela ethembekileyo, esebenzayo yokudala i-welds eqinile, eqhubekayo. Usetyenziso lwayo lukhulu, lunwenwela kumashishini anjengeemoto, i-aerospace, kunye nokupakishwa, apho imfuno yokungena moya okanye indawo yokuhlangana kwamanzi ibalulekile. Ngokukwazi ukuvelisa i-welds engaguqukiyo, ehlala ixesha elide ngokukhawuleza, i-welding ye-seam yindlela ekhethiweyo yeendawo zokuvelisa umthamo ophezulu.

Nangona kunjalo, kubalulekile ukuqwalasela imida ye-welding ye-seam, ngokukodwa malunga neendleko zezixhobo kunye nokuhambelana kwezinto. Kwiinkampani ezijonge ukutyala imali kwi-welding ye-seam, izibonelelo zokunyuka kwemveliso, ingqibelelo eyomeleleyo ye-weld, kunye nokuhambelana ne-automation kuyenza ibe yinto exabisekileyo kuyo nayiphi na inkqubo yokuvelisa.

Ixesha lokuposa: Oct-09-2024