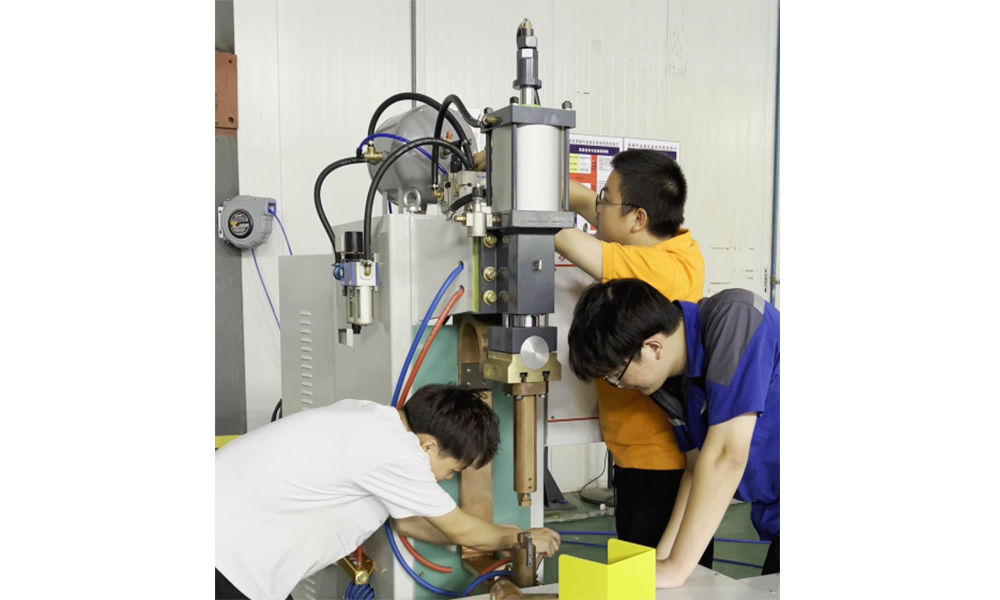

Spot welderszixhobo ezisetyenziswa ngokuqhelekileyo kumashishini ahlukeneyo, asetyenziswa ngokubanzi ukudibanisa ngokuchanekileyo nangokufanelekileyo iinxalenye zetsimbi, ukwenzela ukuba kuqinisekiswe ukusebenza kwayo kakuhle kunye nobomi benkonzo, ukuhlolwa rhoqo kunye nokugcinwa kwezixhobo kubalulekile, eli nqaku liza kuthetha malunga nokuba yintoni ekufuneka ithathelwe ingqalelo xa ukwenza uhlolo lwe-spot welder.

- Ukhuseleko kuqala:Ngaphambi kokuqala naluphi na ukuhlolwa, kuyimfuneko ukuqinisekisa ukuba umatshini unqanyuliwe kunikezelo lwamandla ukukhusela ukuqala ngengozi ngexesha lokuhlola. Ukongeza, nxiba ngokufanelekileyoizixhobo zokuzikhusela(PPE), njengeeglavu kunye neeglasi zokhuseleko. Zikhusele kwiingozi ezinokubakho.

- Uhlolo lwangaphandle:Okokuqala jonga amacandelo angaphandle e-welder, khangela iintambo, izihlanganisi, i-electrode kunye nezixhobo ezicacileyo zokuguga okanye umonakalo, kwaye uqinisekise ukuba inkqubo yokufudumeza isebenza ngokufanelekileyo kwaye ukujikeleza okupholileyo akunaziphene.

- Imeko ye-Electrode: Imeko ye-Electrode inempembelelo ebalulekileyo kumgangatho we-welding. Khangela ukuba i-electrode inempembelelo, i-deformation okanye iimpawu ze-pitting, ukuba i-electrode ine-phenomenon yokugqoka, ingaba ngumhlaba wokugcina ukuhambelana nokuthembeka kwe-welding.

- Ukuhlolwa kwentambo kunye noqhagamshelo:Qwalasela iintambo ezidityanisiweyo kunye nokudityaniswa kweempawu zomonakalo, ukuvezwa, okanye ukuqhagamshelwa okuxekethileyo. Ukungaphumeleli kwekhebula kunokubangela i-arcing, enokuba yingozi kwaye ichaphazele umgangatho we-weld.

- Ubonelelo lwamandla kunye nolawulo:Jonga unikezelo lwamandla kunye nephaneli yokulawula iimpazamo. Khangela ukuba onke amaqhosha, iiswitshi, kunye namaqhina asebenza ngokufanelekileyo ukuqinisekisa ukuba aphendula njengoko kulindelekile.

- Inkqubo yokupholisa:Isixokelelwano sokupholisa siyimfuneko ukuze kuthintelwe ukushisa okukhulu ngexesha elide lokusebenza. Khangela ukuba inqanaba lesipholisi kwidama lokupholisa liqhelekile, kwaye khangela ukuba umgca wokupholisa awuvaleki na, kwaye ukuba kuyimfuneko, kufuneka uwucoce okanye uwutshintshe.

- Ukubeka umhlaba kunye nokugquma: Isiseko esifanelekileyo sibaluleke kakhulu kukhuseleko lombane kunye ne-welding esebenzayo. Qwalasela uqhagamshelo lomhlaba kwaye uqinisekise ukuba iintambo neengcingo zomelele kwaye azinamhlwa ukuthintela imijikelezo emifutshane yombane.

- Umgangatho weWeld:Iimvavanyo ze-weld zenziwa kwizinto zesampulu ukuvavanya umgangatho we-weld kunye nokuhambelana. Ukuba kukho naziphi na izitenxo ezifunyenweyo, zingabonisa ingxaki ngokuseta umatshini, i-electrodes, okanye amanye amacandelo.

- Ugcino:Khangela ukugcinwa komatshini ukuqinisekisa ukugcinwa rhoqo kunye nokulinganisa, okufuneka uyenze ngexesha elifanelekileyo ukuphepha iingxaki ezingaphezulu.

- Uhlolo lobuchwephesha:Nangona ukuhlolwa okubonakalayo rhoqo kubalulekile, kucetyiswa ukuba izixhobo zihlolwe rhoqo nguchwepheshe oqeqeshiweyo. Ukuhlolwa kobuchwephesha kunokufumanisa iingxaki ezinokuthi zingabonakali ngexesha lokuhlola okubonakalayo.Ukulawula i-welder kwindawo ephakathi ngokuqhelekileyo kufuna ingqalelo ngenyameko kuzo zonke iinkalo, ukusuka kumanyathelo okhuseleko ukuya kwimeko ye-electrodes, iintambo, ulawulo kunye neenkqubo zokupholisa. Ngolawulo olubanzi kunye nokulungelelanisa, unokuphucula ukusebenza kunye nokwandisa ubomi be-welder, ukunciphisa ixesha lokunciphisa kunye nokuqinisekisa ukusebenza okukhuselekileyo. Kuyimfuneko kwizicelo ezahlukeneyo zoshishino.

Ukulawula i-welder kwindawo ephakathi ngokuqhelekileyo kufuna ingqalelo ngenyameko kuzo zonke iinkalo, ukusuka kumanyathelo okhuseleko ukuya kwimeko ye-electrodes, iintambo, ulawulo kunye neenkqubo zokupholisa. Ngolawulo olubanzi kunye nokulungelelanisa, unokuphucula ukusebenza kunye nokwandisa ubomi be-welder, ukunciphisa ixesha lokunciphisa kunye nokuqinisekisa ukusebenza okukhuselekileyo. Kuyimfuneko kwizicelo ezahlukeneyo zoshishino.

Ixesha lokuposa: Aug-20-2024