Umshini wokushisela indawo we-ADB-260 MFDC

Isingeniso Somkhiqizo

Isingeniso Somkhiqizo

-

01 Ingakwazi ukucindezela ngempumelelo i-spatter yokushisela futhi ithole imiphumela ezinzile nesezingeni eliphezulu

Ukunikezwa kokushisa okuqhubekayo okukhiqizwa yi-flat output current yomshini wokushisela imvamisa ephakathi kwenza izinga lokushisa le-nugget likhuphuke ngokuqhubekayo. Ngesikhathi esifanayo, ukulawulwa okunembile kwe-slope yamanje ekhuphukayo kanye nesikhathi ngeke kubangele i-spatter ngenxa yokushisa kokushisa kanye nesikhathi sokukhuphuka kwamanje esingalawuleki. Khiqiza.

-

02 Amandla amafushane ngesikhathi, ukusebenza kahle kokushisa okuphezulu, umumo omuhle wokushisela

I-intermediate frequency inverter spot welder inomshini wokushisela ophumayo oyisicaba, oqinisekisa ukusebenza kahle okuphezulu nokunikezwa okuqhubekayo kokushisa kokushisela. Futhi isikhathi sokusebenza kwamandla sifushane, sifinyelela izinga le-ms, okwenza indawo ye-welding ethinteke ukushisa ibe yincane, futhi amalunga e-solder akhiwe kahle.

-

03 Ukunemba kokulawula okuphezulu

Ngenxa yefrikhwensi ephezulu yokusebenza (imvamisa engu-1-4KHz) yomshini wokushisela we-intermediate frequency spot welding, ukunemba kokulawula impendulo izikhathi ezingama-20-80 zomshini wokushisela indawo we-AC ojwayelekile kanye nomshini wokushisela wendawo yokulungisa, kanye nokulawula okukhiphayo okuhambisanayo. ukunemba nakho kuphezulu kakhulu.

-

04 Ukonga amandla

ukonga amandla. Ngenxa yokusebenza kahle kokushisa okuphezulu, i-welding transformer encane kanye nokulahlekelwa okuncane kwensimbi, umshini wokushisela inverter ungonga amandla angaphezu kuka-30% kunomshini wokushisela indawo ye-AC kanye nomshini wokushisela wendawo wokulungisa lapho ushisela isiqeshana sokusebenzela esifanayo.

-

05 Umshini wokushisela indawo ye-Inverter ulungele ibhalansi kagesi wegridi, ngaphandle kwemishini yesinxephezelo samandla

Isetshenziselwa ukushisela indawo kanye ne-nati projection welding yensimbi enamandla kakhulu kanye nensimbi eyakhiwe eshisayo embonini yokukhiqiza izimoto, ukushisela indawo kanye ne-multi-point projection welding yepuleti lensimbi elinekhabhoni eliphansi, ipuleti lensimbi engagqwali, ipuleti elinothayela, ipuleti le-aluminium, i-resistance brazing kanye ne-spot welding ye-copper wire embonini kagesi yamandla aphezulu naphansi, ukushisela indawo eyisiliva, ukubhula amapuleti ethusi, ukushisela indawo yesiliva eyinhlanganisela, njll.

Amasampula Welding

Amasampula Welding

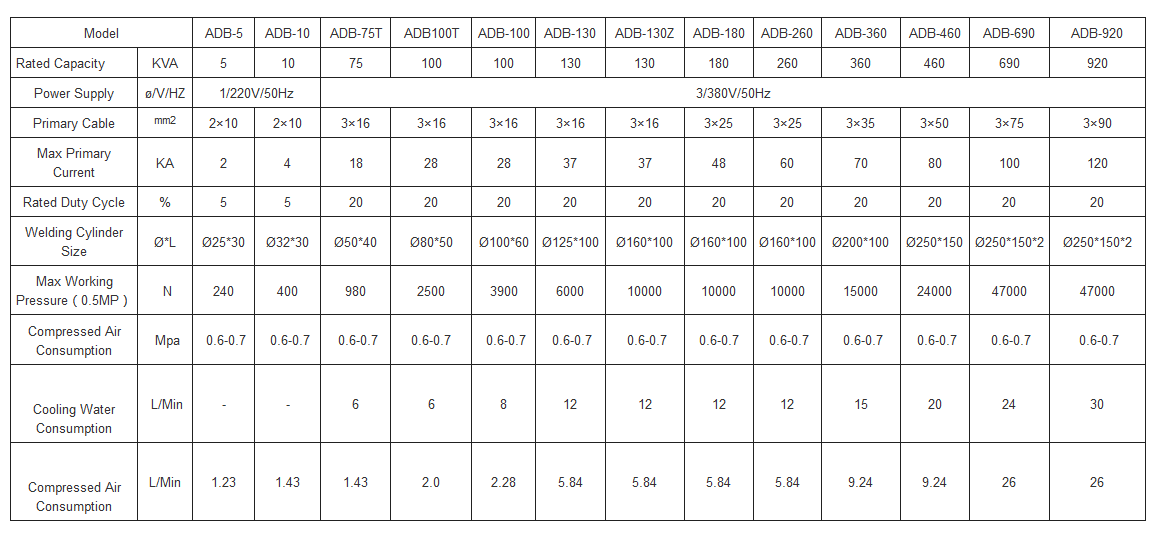

Welder Imininingwane

Welder Imininingwane

Inqubo Ngokwezifiso

Inqubo Ngokwezifiso

I-Welder FAQ

I-Welder FAQ

- Q: Ungaqinisekisa kanjani ukuphepha komshini wokushisela indawo?

IMP: Izinqubo eziphephile zokusebenza zidinga ukulandelwa lapho kusetshenziswa i-spot welder, okuhlanganisa ukugqoka igiya lokuphepha, ukuqinisekisa ukuthi okokusebenza kusebenza kahle, nokugwema ukuthinta izintambo eziveziwe.

- Q: Ingabe Ama-Spot Welders Adinga Ukunakekelwa Njalo?

IMP: Yebo, ukunakekelwa okuvamile kuzogcina i-spot welder yakho isebenza kahle kakhulu futhi kwelule impilo yesisetshenziswa sakho.

- Q: Kuhlanganisani ukugcinwa komshini wokushisela indawo?

IMP: Ukunakekelwa kwe-spot welder kuhlanganisa ukuhlanza okokusebenza, ukufaka izingxenye ezigugile, ukuhlola izintambo zikagesi nezamandla, kanye nokuhlola ngezikhathi ezithile isimo sokusebenza kwesisetshenziswa.

- Umbuzo: Iyiphi i-electrode engiyidingayo ukuze ngishisele indawo?

A: Ukukhethwa kwama-electrode kufanele kunqunywe ngokusho kohlobo kanye nempahla yephrojekthi yokushisela.

- Q: Ungabhekana kanjani nokugqoka kwe-electrode ngesikhathi sokusetshenziswa komshini wokushisela indawo?

A: Uma i-electrode isigugile, kufanele ishintshwe ngesikhathi ukuze kuqinisekiswe ukusebenza kahle kwemishini.

- Q: Ungakhetha kanjani ingcindezi efanele yomshini wokushisela indawo?

A: Ukucindezela okufanele kufanele kunqunywe ngokusho kohlobo kanye nempahla yephrojekthi yokushisela ukuze kuqinisekiswe imiphumela engcono kakhulu ye-welding.

Thumela i-imeyili kithi

Thumela i-imeyili kithi