Umshini wokushisela indawo we-ADB-360 MFDC

Isingeniso Somkhiqizo

Isingeniso Somkhiqizo

-

Cindezela ngempumelelo i-welding spatter futhi uzuze imiphumela ezinzile nesezingeni eliphezulu

ukunikezwa kokushisa okuqhubekayo okukhiqizwa yi-flat output current yomshini wokushisela imvamisa ephakathi kwenza izinga lokushisa le-nugget likhuphuke ngokuqhubekayo. Ngesikhathi esifanayo, ukulawulwa okunembile kwe-slope yamanje ekhuphukayo kanye nesikhathi ngeke kubangele i-spatter ngenxa yokushisa kokushisa kanye nesikhathi sokukhuphuka kwamanje esingalawuleki.

-

Isikhathi esifushane samandla e-welding, ukusebenza kahle okuphezulu kokushisa, nesimo esihle sokushisela

UMA i-inverter spot welder inomshini wokushisela oyisicaba, oqinisekisa ukusebenza kahle okuphezulu nokunikezwa okuqhubekayo kokushisa okushiselayo. Futhi isikhathi sokusebenza kwamandla sifushane, sifinyelela izinga le-ms, okwenza indawo ye-welding ethinteke ukushisa ibe yincane, futhi amalunga e-solder akhiwe kahle.

-

Ukunemba kokulawula okuphezulu

imvamisa yokusebenza ephezulu (imvamisa engu-1-4KHz) yomshini wokushisela imvamisa emaphakathi, ukunemba kokulawula impendulo izikhathi ezingama-20-80 zomshini wokushisela indawo we-AC ojwayelekile kanye nomshini wokushisela wendawo yokulungisa yesibili, kanye nokunemba kokulawula okukhiphayo nakho phezulu kakhulu.

-

Ukonga amandla

ukonga amandla. Ngenxa yokusebenza kahle kokushisa okuphezulu, i-welding transformer encane kanye nokulahlekelwa okuncane kwensimbi, umshini wokushisela inverter ungonga amandla angaphezu kuka-30% kunomshini wokushisela indawo ye-AC kanye nomshini wokushisela wendawo wokulungisa lapho ushisela isiqeshana sokusebenzela esifanayo.

-

Umshini we-inverter spot welding ulungele ibhalansi yokunikezwa kwamandla egridi, ngaphandle kwemishini yesinxephezelo samandla

Isetshenziselwa ukushisela amabala nokushisela amantongomane ensimbi enamandla amakhulu kanye nensimbi eyakhiwe eshisayo embonini yokukhiqiza izimoto, ukushisela indawo kanye ne-multi-point projection welding yepuleti lensimbi eline-carbon ephansi, ipuleti lensimbi engagqwali, ipuleti le-aluminium kanye i-wire, i-resistance brazing kanye ne-spot welding ye-copper wire embonini kagesi yamandla aphezulu naphansi, i- silver spot welding, i-copper plate brazing, inhlanganisela yendawo yesiliva yokushisela, njll.

Amasampula Welding

Amasampula Welding

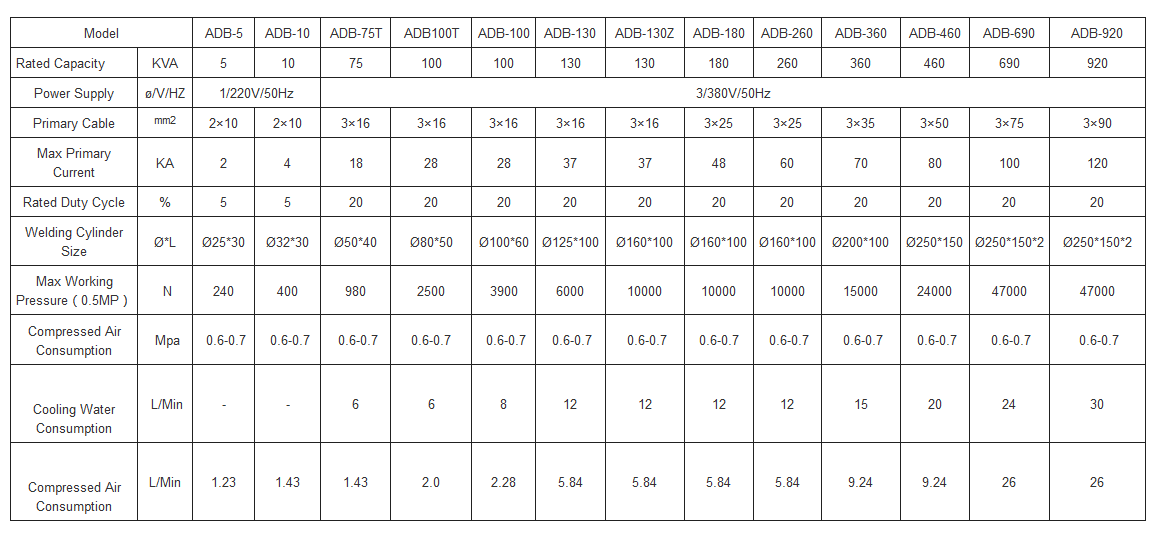

Welder Imininingwane

Welder Imininingwane

Inqubo Ngokwezifiso

Inqubo Ngokwezifiso

I-Welder FAQ

I-Welder FAQ

- Q: Kukangaki ukugcinwa kwe-spot welder?

IMP: Imvamisa yokulungiswa kufanele inqunywe ngokuya ngokusetshenziswa kwe-spot welder nendawo yokukhiqiza, futhi kuvame ukutuswa ukwenza ukulungiswa kanye ngenyanga.

- Q: Ungakhetha kanjani ugesi ofanele womshini wokushisela indawo?

A: Ukukhethwa kokunikezwa kwamandla omshini wokushisela indawo kufanele kunqunywe ngokuvumelana namandla emishini kanye nendawo yokusetshenziswa ukuze kuqinisekiswe ukuthi okokusebenza kungasebenza ngokujwayelekile.

- Q: Hlobo luni lwezinyathelo zokuvikela abashiseli bamabala okudingeka bazisebenzise?

IMP: Ama-Spot welders adinga ukusetshenziswa kwezingilazi zokuzivikela, amagilavu, namanye amathuluzi okuphepha ukuze kugcinwe abaqhubi bephephile.

- Q: Kufanele uxhunywe kanjani amandla omshini wokushisela indawo?

A: Ukunikezwa kwamandla kufanele kuxhunywe ngokuya ngezidingo zikagesi namazinga okuphepha emishini.

- Q: Ingakanani impilo yesevisi ye-spot welder?

A: Impilo yesevisi yomshini wokushisela indawo incike ezintweni ezifana nekhwalithi yemishini, ukugcinwa kanye nemvelo yokusebenzisa, ngokuvamile phakathi kweminyaka engu-5-10.

- Q: Iyini ijubane lokushisela le-welder yendawo?

A: Isivinini sokushisela sincike kusayizi kanye yinkimbinkimbi yephrojekthi yokushisela futhi ngokuvamile izikhathi eziningana ngomzuzwana.

Thumela i-imeyili kithi

Thumela i-imeyili kithi