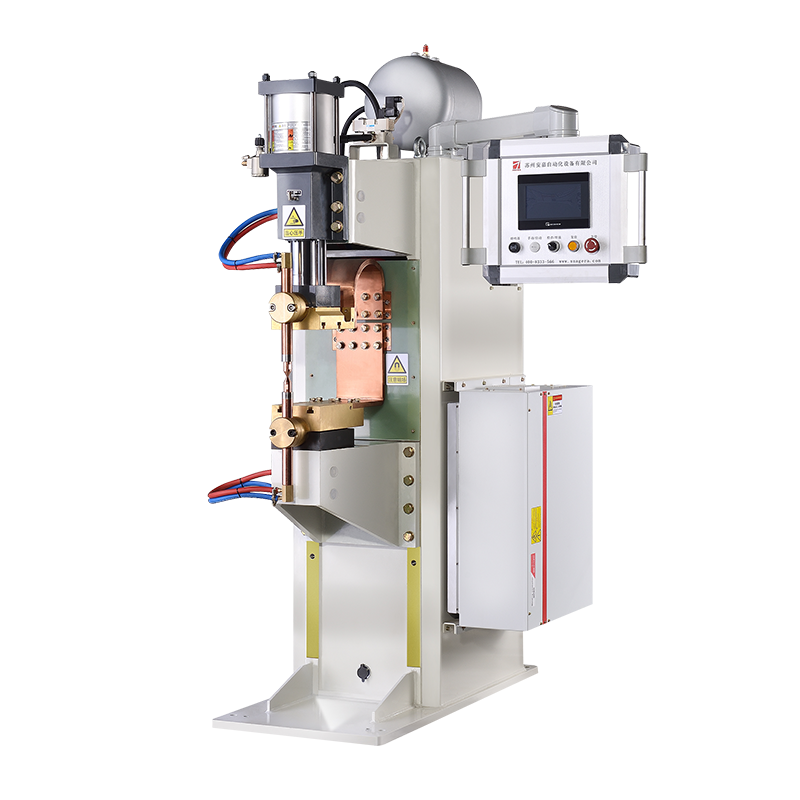

I-ADB-460 Resistance spot welding machine

Isingeniso Somkhiqizo

Isingeniso Somkhiqizo

-

cindezela ngempumelelo i-welding spatter

Ukunikezwa kokushisa okuqhubekayo okukhiqizwa amandla akhona ayisicaba eshisela indawo ye-IF kwenza izinga lokushisa le-nugget likhuphuke ngokuqhubekayo. Ngesikhathi esifanayo, ukulawulwa okunembile kwe-slope yamanje ekhuphukayo kanye nesikhathi ngeke kubangele i-spatter ngenxa yokushisa kokushisa kanye nesikhathi sokukhuphuka kwamanje esingalawuleki.

-

Isikhathi esifushane samandla, ukusebenza kahle kokushisa okuphezulu

I-IF spot welder inomshini wokushisela ophumayo oyisicaba, oqinisekisa ukusebenza kahle okuphezulu nokunikezwa okuqhubekayo kokushisa kokushisela. Futhi isikhathi sokusebenza kwamandla sifushane, sifinyelela izinga le-ms, okwenza indawo ye-welding ethinteke ukushisa ibe yincane, futhi amalunga e-solder akhiwe kahle.

-

Ukunemba kokulawula okuphezulu

Ngenxa yemvamisa yokusebenza ephezulu (imvamisa engu-1-4KHz) ye-intermediate frequency Inverter spot welder, ukunemba kokulawula impendulo izikhathi ezingama-20-80 zomshini wokushisela indawo we-AC kanye nomshini wokushisela wendawo yokulungisa, kanye nokulawula okukhiphayo okuhambisanayo. ukunemba nakho kuphezulu kakhulu.

-

Ukonga amandla 30%

Yonga amandla, yonga amandla okushisela endaweni ngayinye, futhi ufinyeze umjikelezo wokushisela, ofaneleka kakhulu ukushisela ama-workpieces aminyene nezinsimbi ezisebenza kakhulu.

-

Ukulayisha ukulinganisa kwemishini

Isetshenziselwa ukushisela indawo kanye ne-nati projection welding yensimbi enamandla amakhulu kanye nensimbi eyakhiwe eshisayo embonini yokukhiqiza izimoto, ukushisela indawo kanye ne-multi-point projection welding yepuleti lensimbi eline-carbon ephansi, ipuleti lensimbi engagqwali, ipuleti le-aluminium kanye nocingo, ukumelana. ukubhula nokushisela amabala kocingo lwethusi embonini kagesi yamandla aphezulu naphansi, ukubhula amapuleti ethusi, ukushisela indawo yesiliva eyinhlanganisela, njll.

Amasampula Welding

Amasampula Welding

Ipuleti le-aluminium

I-French hex nut

Ukuxhumana okuthambile kwe-motor stator

high-amandla steel isihlalo sokuhlola ipuleti

ukuqinisa ubambo

inati eliyindilinga

I-valve yokuchichima yesistimu ye-hydraulic

isilungisi sesihlalo

ipuleti elinesiliva

insimbi engagqwali

i-terminal wire

Ipayipi lepuleti elingaphakathi le-longitudinal langaphambili elinentambo

Welder Imininingwane

Welder Imininingwane

Amapharamitha we-Welding

Amapharamitha we-Welding

| Imodeli | I-ADB-5 | I-ADB-10 | I-ADB-75T | I-ADB100T | I-ADB-100 | I-ADB-130 | I-ADB-130Z | I-ADB-180 | I-ADB-260 | I-ADB-360 | I-ADB-460 | I-ADB-690 | I-ADB-920 | |

| Amandla alinganiselwe | I-KVA | 5 | 10 | 75 | 100 | 100 | 130 | 130 | 180 | 260 | 360 | 460 | 690 | 920 |

| Ukunikezwa kwamandla kagesi | noma V/HZ | 1/220V/50Hz | 3/380V/50Hz | |||||||||||

| Ikhebula Eliyinhloko | mm2 | 2×10 | 2×10 | 3×16 | 3×16 | 3×16 | 3×16 | 3×16 | 3 × 25 | 3 × 25 | 3x35 | 3 × 50 | 3 × 75 | 3x90 |

| I-Max Primary Yamanje | KA | 2 | 4 | 18 | 28 | 28 | 37 | 37 | 48 | 60 | 70 | 80 | 100 | 120 |

| Umjikelezo Wemisebenzi Elinganiselwe | % | 5 | 5 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Welding Cylinder Usayizi | Ø*L | Ø25*30 | Ø32*30 | Ø50*40 | Ø80*50 | Ø100*60 | Ø125*100 | Ø160*100 | Ø160*100 | Ø160*100 | Ø200*100 | Ø250*150 | Ø250*150*2 | Ø250*150*2 |

| I-Max Working Pressure (0.5MP) | N | 240 | 400 | 980 | 2500 | 3900 | 6000 | 10000 | 10000 | 10000 | 15000 | 24000 | 47000 | 47000 |

| Ukusetshenziswa Komoya Ocindezelwe | Mpa | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 |

|

Ukusetshenziswa Kwamanzi Okupholisa | L/Miz | - | - | 6 | 6 | 8 | 12 | 12 | 12 | 12 | 15 | 20 | 24 | 30 |

|

Ukusetshenziswa Komoya Ocindezelwe | L/Miz | 1.23 | 1.43 | 1.43 | 2.0 | 2.28 | 5.84 | 5.84 | 5.84 | 5.84 | 9.24 | 9.24 | 26 | 26 |

Inqubo Ngokwezifiso

Inqubo Ngokwezifiso

I-Welder FAQ

I-Welder FAQ

- Q: Ingabe ama-electrode omshini wokushisela amabala adinga ukushiswa?

A: I-electrode ayidingi ukushisa kwangaphambili, kodwa kwezinye izimo, ukushisa kuqala kungathuthukisa imiphumela yokushisela.

- Q: Hlobo luni lomsindo oluzokhiqizwa ngesikhathi sokushisela isishiseli sendawo?

A: Inqubo yokushisela yomshini wokushisela indawo izoveza umsindo, futhi izinyathelo zokuzivikela ezinjengama-earplugs ziyadingeka.

- Q: Ingabe ukugcinwa komshini wokushisela indawo kungenziwa uwedwa?

A: Eminye imisebenzi yokulungisa ingenziwa uwedwa, kodwa imisebenzi enzima kakhulu izodinga ukwenziwa uchwepheshe oqeqeshiwe.

- Q: Ngabe i-spot welder idinga ukufakwa kuphi?

IMP: Indawo yokushisela idinga ukufakwa endaweni enomoya omuhle, eyomile futhi ixhunywe entanjeni kagesi.

- Q: Kuthatha isikhathi esingakanani ukulungisa isishiseli sendawo?

IMPENDULO: Isikhathi sokulungisa sincike ebunzimeni bomsebenzi wokulungisa kanye nobukhulu bokwehluleka kwezisetshenziswa, futhi ngokuvamile kuthatha amahora kuya ezinsukwini.

- Q: Ngabe ama-spot welders adinga ukuhlanzwa kanjani?

A: Ama-spot welders kufanele ahlanzwe ngomoya ocindezelwe noma okokuhlanza, futhi akufanele ahlanzwe ngamanzi noma ngolunye uketshezi.

Thumela i-imeyili kithi

Thumela i-imeyili kithi