Kunezindlela eziningi zokujoyina izinsimbi, futhi ukushisela kuyindlela edingekayo yokuxhuma izingxenye eziningi zensimbi. Uma umusha embonini yokushisela, ungase ungaboni ukuthi zingaki izinqubo zokushisela ezikhona zokuxhuma izinsimbi. Lesi sihloko sizochaza izinqubo ze-welding eziyinhloko ezingu-8, zikunikeza ukuqonda okujulile kwemboni yokushisela.

I-Arc Welding

I-arc weldingisebenzisa i-arc kagesi ukukhiqiza ukushisa, ukuncibilika nokuhlanganisa izinsimbi ndawonye. Lena inqubo yokushisela evame kakhulu futhi ihlanganisa amasu afana nokushisela i-arc manual kanye nokushisela okuvikelwe ngegesi.

I-arc welding ye-manual ilungele insimbi yesakhiwo.

Ukushisela okuvikelwe ngegesi kusebenza kahle ezintweni ezifana nensimbi engagqwali ne-aluminium.

Amathiphu: Vikela indawo yokushisela ekufakweni kwe-oxidation nezinhlansi, futhi ulawule izilungiselelo zamanje kanye ne-voltage ukuze uthole imiphumela engcono kakhulu.

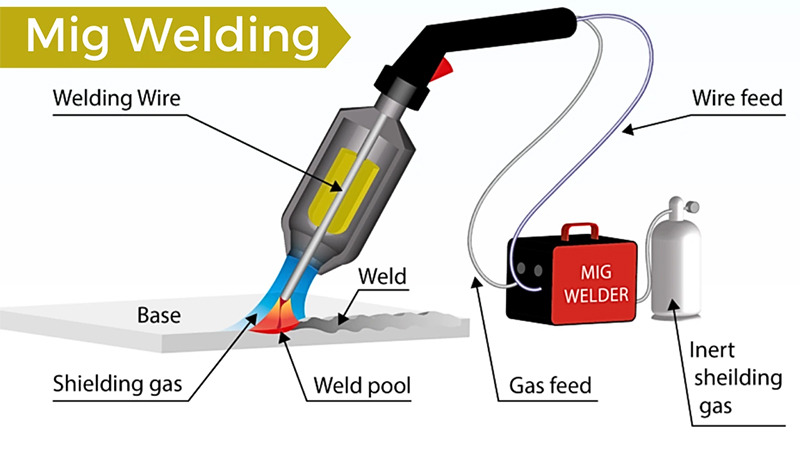

I-MIG/MAG Welding

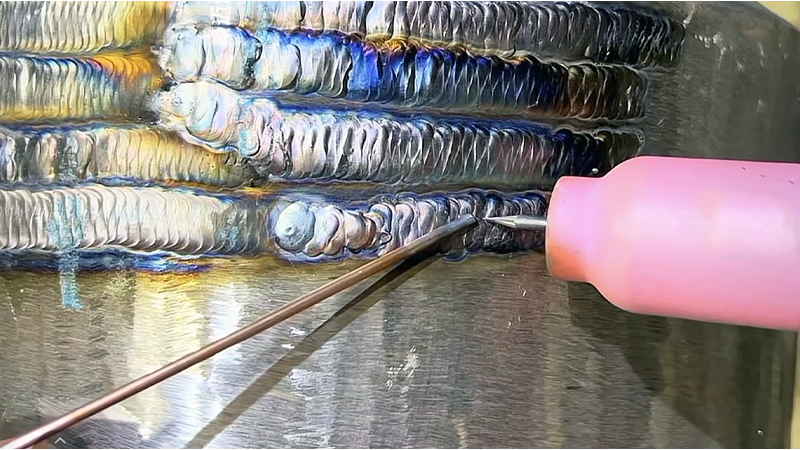

Ukushisela kwe-MIG/MAG kuhilela ukuphakela i-electrode yocingo eqhubekayo ngethoshi yokushisela kuyilapho i-arc incibilikisa ucingo nendawo yensimbi ukuze kwakhe ukushisela. Igesi evikelayo igeleza ngethoshi ukuvikela i-weld ekungcoleni.

Ukushisela kwe-MIGidumile ezimbonini ezifana nezokwakha imikhumbi, ukwakhiwa kwamapayipi, kanye nezakhiwo zensimbi.

Kuhle kuma-workpieces amakhulu, anganyakazi kanye namaphrojekthi okulungisa.

I-TIG Welding

Ukushisa kwe-TIG, noma i-Tungsten Inert Gas welding, isebenzisa i-electrode ye-tungsten engadleki ukuze idale ama-welds anembe kakhulu. Igesi evikelayo, njenge-argon, ivikela indawo yokushisela ekungcoleni.

Ukunemba okuphezulu kuyenza ilungele izinto ezithambile njenge-aluminium nensimbi engagqwali.

Isetshenziswa kakhulu ezimbonini zezimoto, ze-aerospace, nezinembayo.

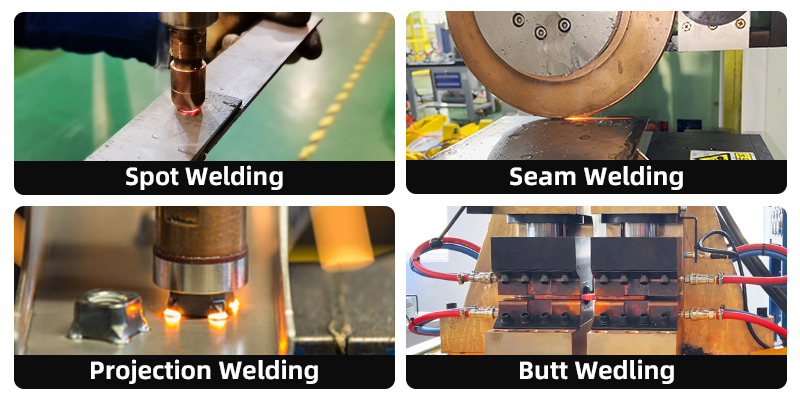

I-Resistance Welding

In ukumelana nokushisela, izingcezu ezimbili zensimbi zicindezelwa phakathi kwama-electrode, futhi amandla kagesi adala ukushisa ukuwahlanganisa. Izinhlobo eziyinhloko zihlanganisa indawo, i-projection, i-butt, ne-seam welding.

I-Resistance welding iyashesha, ayidingi izinto zokugcwalisa, futhi kulula ukuzenzela.

Isetshenziswa kakhulu ezingxenyeni zezimoto, zikagesi, nezinto zikagesi zasendlini. Isibonelo, ilungele ukushisela amantongomane emoto.

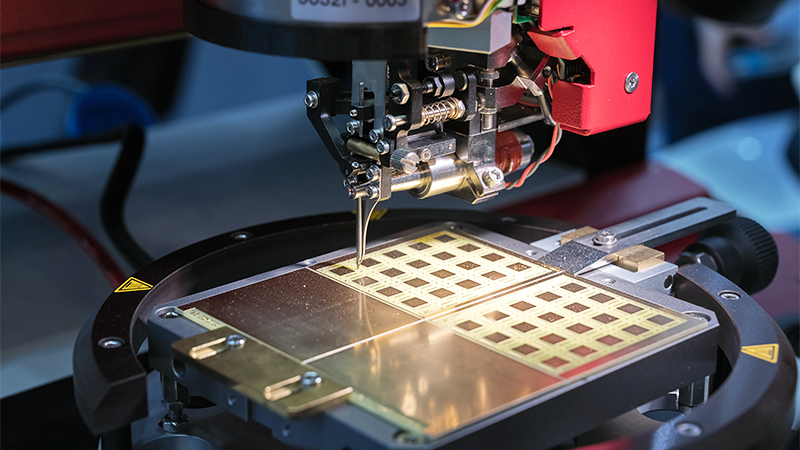

I-Laser Welding

I-laser weldingkuyindlela esebenzisa i-laser beam njengomthombo wamandla wokushisa nokuhlanganisa izinsimbi noma amapulasitiki. Uma kuqhathaniswa nokushisela kwe-arc yendabuko, ukushisela nge-laser kuyashesha futhi kusebenza kahle kakhulu. Ingahlanganiswa kalula nayoi-robot welderfuthi kuyindlela eyinhloko ekucutshungulweni kwezinto ze-laser. I-laser welding ayidingi ama-electrode futhi ayidingi ukuxhumana nezinto zokusebenza. Uma ushisela izinto ezincane noma izintambo ezincane, akubangeli ukuncibilika emuva njengokushisela i-arc.

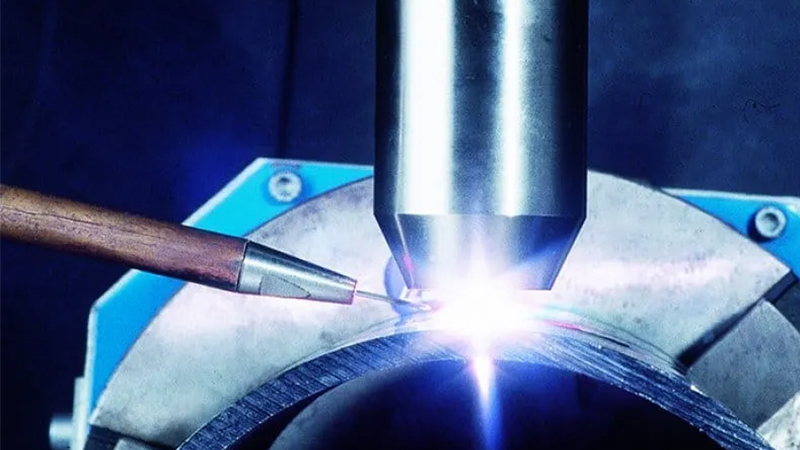

I-Plasma Welding

I-Plasma welding ikhiqiza i-plasma ngokusebenzisa i-arc enamandla amakhulu, encibilikisa ucezu lokusebenza. Izinto zokugcwalisa ziyengezwa ukuze kuhlanganiswe izinsimbi.

Isebenza ngezinsimbi, ipulasitiki, nezitsha zobumba.

Isetshenziswa kaningi ekukhiqizeni i-aerospace, izimoto, nezinto zikagesi.

I-Ultrasonic Welding

I-Ultrasonic welding isebenzisa ukudlidliza kwemvamisa ephezulu ezindaweni ezimbili ezingaphansi kwengcindezi, okuzibangela ukuthi zihlangane ngaphandle kokuncibilika. Le nqubo isebenzela izinsimbi, amapulasitiki, ngisho nezinto ezingafani.

Ikhiqiza amalunga aqondile, ahlanzekile futhi kulula ukuwenza ngokuzenzakalelayo.

Okujwayelekile ezimbonini ezidinga ukushiselwa okuhle, okuqinile.

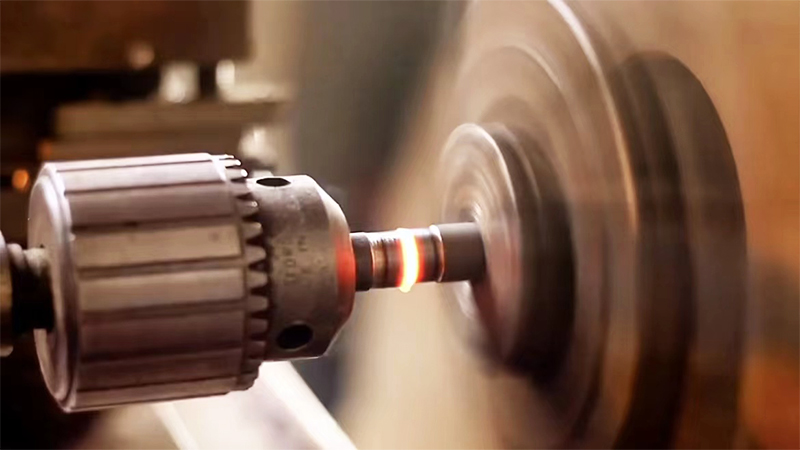

I-Friction Welding

I-friction welding idala ukushisa ngokuhlikihlwa ngokushesha kwezindawo ezimbili, kuzithambisa ukuze kwakhe isibopho esiqinile. Le nqubo yesimo esiqinile iqeda isidingo somthombo wokushisa wangaphandle.

Ivimbela ukukhubazeka njengokubola nokuqhekeka.

Isetshenziswa kakhulu ekukhiqizweni kwezimboni, njengamasondo endiza nama-ekseli wesitimela.

Indlela Yokukhetha Inqubo Yokushisela Elungile

Lapho ukhetha inqubo ye-welding, cabanga:

Uhlobo lwezinto ezibonakalayo (isb, i-aluminium, insimbi engagqwali)

Usayizi we-Workpiece nobukhulu

Izidingo zokunemba

Ukuthi i-automation iyadingeka

Ukuhlola izindlela eziningi kungakusiza ukuthi uthole isixazululo esingcono kakhulu sephrojekthi yakho ethile.

Ngokuqonda lezi zinqubo zokushisela eziyinhloko ezingu-8, ungakhetha indlela efanele yephrojekthi yakho futhi uhlole amathuba amasha embonini yokushisela.

imibuzo ejwayelekile ukubuzwa

1. Iyiphi inqubo ye-welding engcono kakhulu yezingxenye zezimoto?

I-Resistance welding iyinketho ephezulu yezingxenye zezimoto ngenxa yesivinini sayo esisheshayo, isiphetho sobuhle, kanye ne-automation elula.

2. Yiziphi izinto ezingafakwa ezishiselwe?

Ungakwazi ukushisela izinhlobonhlobo zezinsimbi, okuhlanganisa insimbi engagqwali, ithusi, i-aluminium, nensimbi.

3. Ingabe zonke izinqubo zokushisela zisebenzisa izinsimbi zokugcwalisa?

Cha. Isibonelo, i-resistance welding ayidingi izinduku zokugcwalisa.

4. Ngingawafunda kuphi amanye amakhono okushisela?

Ungaya ezikoleni eziyisipesheli zemisebenzi yezandla noma uthole ulwazi olunzulu ngezindawo zokukhiqiza.

Isikhathi sokuthumela: Oct-21-2024