Ukushisela insimbi engagqwali kudinga amasu akhethekile kanye nokulungiselela ngokucophelela ngenxa yezakhiwo zayo eziyingqayizivele.Insimbi engagqwaliisetshenziswa kakhulu ezimbonini ezifana nokucubungula ukudla, ezemithi, i-aerospace, nezokwakha ngenxa yokumelana nokugqwala okuphezulu, amandla, kanye nokukhanga kobuhle. Kodwa-ke, lezi zimfanelo ezifanayo zenza kube nzima kakhulu ukushisela uma kuqhathaniswa nensimbi ethambile.

Kulo mhlahlandlela, thina'izohlanganisa izimiso eziyisisekelo zokushisela insimbi engagqwali, izinselele ezivezayo, kanye nemikhuba engcono kakhulu yokuzuza ukushisela kwekhwalithi ephezulu. Noma ngabe ungumuntu osaqalayo noma umshiseli onesipiliyoni, ukuqonda le miqondo kuzokusiza ukuthi uthole imiphumela engashintshi uma usebenza ngensimbi engagqwali.

Izakhiwo Zensimbi Engagqwali

Insimbi engagqwali iqukethe okungenani i-chromium engu-10.5%, eyenza ungqimba lwe-oxide ye-passive ebusweni, inikeze ukumelana nokugqwala. Izinhlobo ezahlukahlukene zensimbi engagqwali, njenge-austenitic, i-ferritic, i-martensitic, ne-duplex, zinikeza inhlanganisela ehlukene yamandla, ukushisela, nokumelana nokugqwala.

Izici zensimbi engagqwali ezithinta ukushisela zihlanganisa:

Ukunwetshwa Okushisayo Okuphezulu: Insimbi engagqwali inweba ngaphezu kwe-carbon steel uma ishiswa, okwandisa ingozi yokungqubuzana nokuhlanekezela ngesikhathi sokushisela.

I-Low Thermal Conductivity: Ukushisa akushabalali kalula, okuholela ekuhlanganiseni kokushisa endaweni yokushisela, okungabangela ukusha.

Ukuzwela Ekushiseni: Okokufaka ukushisa okudlulele kungabangela ukushintsha kombala noma kunciphise ukumelana nokugqwala.

Ukwakhiwa KweCarbides: Ukwakheka kwe-Chromium carbide kungenzeka emazingeni okushisa aphezulu, kunciphisa ukumelana nokugqwala (into eyaziwa ngokuthi ukuzwela).

Izinhlobo Zensimbi Engagqwali Yokushisela

1. I-Austenitic Stainless Steel (300 Series)

Izici: Akunazibuthe, ukumelana nokugqwala, futhi kulula ukusebenza ngakho.

Amabanga ajwayelekile: 304 kanye ne-316.

Ukushisela: Kuhle, kodwa kujwayele ukuhlanekezelwa ngenxa yokwanda okushisayo okushisayo.

2. I-Ferritic Stainless Steel (400 Series)

Izici: I-Magnetic, ukumelana nokugqwala okuphansi kunezinhlobo ze-austenitic kodwa i-thermal conductivity ephakeme.

Amabanga ajwayelekile: 430.

Ukushisela: Okumaphakathi; idinga ukwelashwa kokushisa kwangaphambili nangemuva kwe-weld ukugwema ukuqhekeka.

3. I-Martensitic Stainless Steel

Izici: Amandla aphezulu, ukumelana nokuguga, nokumelana nokugqwala okulinganiselwe.

Amabanga ajwayelekile: 410 kanye nama-420.

Ukushisela: Kunzima; kudinga ukulawula ngokucophelela ukushisa ukugwema ukuqhekeka.

4. I-Duplex Stainless Steel

Izici: Inhlanganisela yezinto ze-austenitic ne-ferritic, enikeza amandla aphezulu kanye nokumelana nokugqwala.

Amabanga ajwayelekile: 2205.

Ukushisela: Kudinga okokufaka okushisa okuphansi ukuze kuvinjwe i-embrittlement.

Izindlela zokushisela zensimbi engagqwali

Okulungele kakhulu: Amashidi ensimbi engenasici nezinhlelo zokusebenza ezidinga ukunemba okuphezulu.

Izinzuzo: Amashisela ahlanzekile, anembe ane-spatter encane.

Okucatshangwayo: Idinga u-opharetha onekhono kanye nesivinini sokushisela esinensayo.

Kuhle kakhulu: Amaphrojekthi amakhulu lapho isivinini sibalulekile.

Izinzuzo: Ngokushesha kune-TIG welding futhi kulula ukuyifunda.

Okucatshangelwayo: Ingakhiqiza i-spatter futhi idinga igesi evikelayo (ngokuvamile i-argon noma ingxube ne-CO₂).

Okulungele kakhulu: Amaphrojekthi angaphandle nezingxenye zensimbi engagqwali ezishubile.

Izinzuzo: Ayifuni't idinga igesi yokuvikela, iyenze ifanelekele umsebenzi wangaphandle.

Okucatshangelwayo: Kungaba nzima ukulawula kunsimbi encane engagqwali.

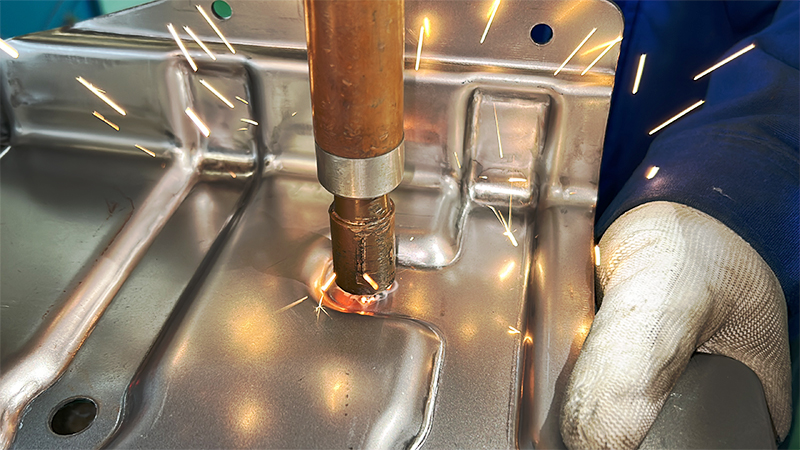

Okulungele kakhulu: Amashidi azacile kuzinhlelo zokusebenza zezimoto nezezimboni.

Izinzuzo: Kuyashesha futhi kusebenza kahle kumajoyinti agqagqene.

Okucatshangwayo: Kukhawulelwe ezinhlotsheni ezithile ezihlangene.

Imikhuba Engcono Kakhulu Yokushisela Insimbi Engagqwali

Ukulungiselela

Hlanza izindawo ezingaphezulu kahle ukuze ususe ukungcola, amafutha kanye ne-oxidation. Ukungcola kungabangela ukukhubazeka kwe-weld futhi kunciphise ukumelana nokugqwala.

Sebenzisa amathuluzi azinikele (amabhulashi, izigayo) ensimbi engagqwali ukuze uvimbele ukungcoliswa kwezinye izinsimbi.

Ukukhethwa Kwegesi Yokuvikela

Ukuze uthole ukushisela kwe-TIG, sebenzisa i-argon engu-100% noma ingxube ye-argon-helium.

Nge-MIG welding, ingxube ye-argon ne-CO₂noma umoya-mpilo uthuthukisa ukungena kwe-weld nokuzinza.

Lawula Okokufaka Ukushisa

Sebenzisa okokufaka okuphansi okungaba khona kokushisa ukuze ugweme ukungqubuzana, ukushintsha kombala, nokwakheka kwe-carbide.

Uma kungenzeka, sebenzisa i-pulse welding ukulawula ukugeleza kokushisa ngokunembe kakhudlwana.

Nciphisa Ukuhlanekezela

Bamba ama-workpieces ngokuqinile ukuze unciphise ukunyakaza ngesikhathi sokushisela.

Sebenzisa i-backstepping (ukushisela izingxenye ezincane ezindaweni ezishintshanayo) ukuze usabalalise ukushisa ngokulinganayo.

Ukuhlanza Nokuqeda Ngemva Kokushisela

Susa noma yikuphi ukushintsha kombala ngamabhulashi ensimbi engagqwali noma izihlanzi zamakhemikhali ukuze ubuyisele ukumelana nokugqwala.

Sebenzisa amasu okunciphisa ukuze ususe ukungcoliswa kwendawo futhi uthuthukise isendlalelo se-oxide.

Ukugwema Imifantu kanye Nokuzwela

Ezingxenyeni eziminyene, ukushisa kuqala insimbi kungasiza ukunciphisa ingozi yokuqhekeka.

Sebenzisa amabanga anekhabhoni ephansi (afana no-304L noma 316L) ukuze ugweme ukwakheka kwe-chromium carbide.

Ukukhubazeka Okujwayelekile ku-Stainless Steel Welding

I-Warping and Distortion: Ibangelwa ukufakwa kokushisa okudlulele kanye nokwanda kwe-thermal.

I-Burn-through: Kuvela lapho ukushisa kuncibilika kumpahla, evame ukubonakala ngezinsimbi ezizacile.

Ukuqhekeka: Ngokuvamile ngenxa yokuphathwa kabi kokushisa noma ukungcoliswa.

I-Porosity: Ibangelwa amagesi avaleleke ku-weld pool, ngokuvamile ngenxa yegesi evikelayo enganele.

Ukushintsha umbala: Ukushisa ngokweqile kungabangela i-oxidation, okuholela endaweni enombala wothingo.

Izicelo Stainless Steel Welding

Izisetshenziswa Zokucubungula Ukudla: Insimbi engagqwali ivamise ukusetshenziselwa amathangi, amapayipi, nezindawo lapho kukhiqizwa ukudla ngenxa yokumelana nokugqwala kanye nokuhlanzeka kalula.

Amadivayisi Emithi Nezokwelapha: Amathuluzi okuhlinza, izimila, neziqukathi eziyinyumba zidinga amashisela anembile, ahlanzekile.

Imboni ye-Aerospace: Insimbi engagqwali isetshenziswa ezingxenyeni zendiza ngamandla ayo kanye nokumelana namazinga okushisa aphezulu.

I-Architecture Nokwakhiwa: Ama-handrail, ama-facade, nezinye izakhi zesakhiwo zisebenzisa insimbi engagqwali ukuze ziqine kanye nobuhle.

Imboni Yezimoto: Amasistimu wokukhipha umoya, amathangi kaphethiloli, nezinsimbi zokuhlobisa ngokuvamile zenziwe ngensimbi engagqwali.

Isiphetho

Ukushisela insimbi engagqwali kuyisayensi kanye nobuciko, okudinga ukuqonda izici nezinselele zezinto ezihlukile. Ngamasu afanele, ukulungiswa, kanye nemishini, ungafinyelela izinga eliphezulu, amashisela aqinile agcina impahla's amandla nokumelana nokugqwala.

Noma ngabe wenza izingxenye zemboni yezokudla, wakha isici sezakhiwo, noma wakha izingxenye zezimoto ezisebenza kahle kakhulu, ukushisela insimbi engagqwali kunikeza inhlanganisela yobuhle, ukuqina, nokusebenza. Ukulandela izinqubo ezingcono kakhulu nokukhetha indlela efanele yokushisela kuzoqinisekisa imiphumela ephumelelayo yephrojekthi yakho yokushisela insimbi engagqwali.

Isikhathi sokuthumela: Oct-15-2024