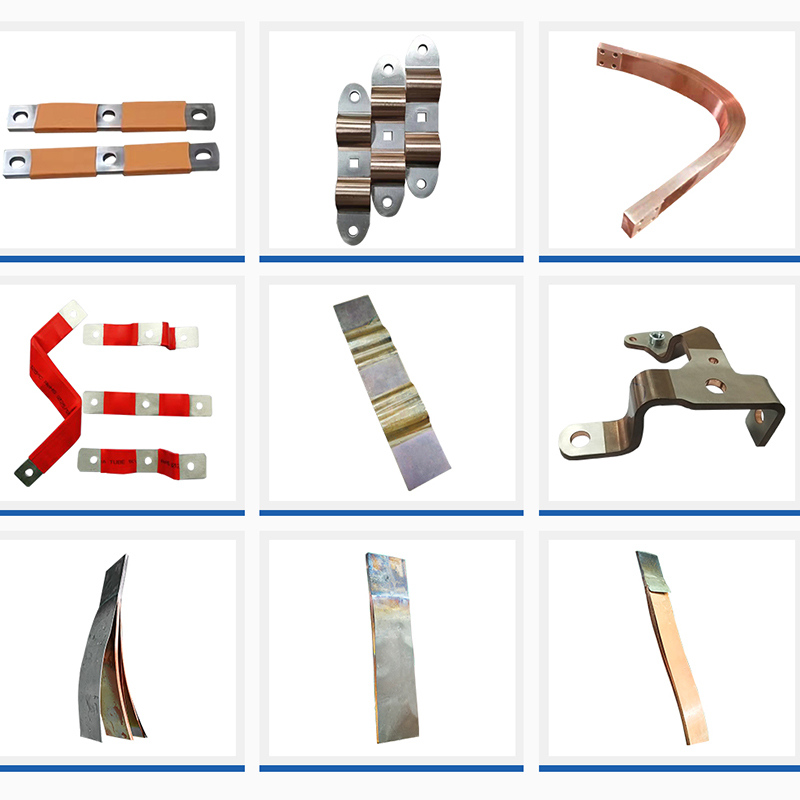

Amabhasizisetshenziswa ngokwandayo emkhakheni wamanje wamandla amasha, okuhlanganisa izimboni ezifana nezimoto zikagesi, ukugcinwa kwamandla, namasistimu kagesi. Njengoba ubuchwepheshe buthuthuka, izinto ze-Busbar zishintshile zisuka ethusi zaya ku-nickel yethusi, i-copper-aluminium, i-aluminium, kanye nezinhlanganisela ze-graphene. Lawa ma-Busbar athembele kakhulu ekwakhiweni nasekushiseleni, njengoba adinga ukuxhuma namabhethri, amasistimu okulawula ugesi, nezinye izakhi. Ukushisela emaphethelweni nasezigabeni ezimaphakathi kubalulekile kulokhu kuxhumana, ngei-welding yokusabalalisaukuba yindlela eyinhloko yokwenza i-Busbar.

Izinhlobo ze-BusbarImishini yokushisela i-Diffusion

Kunezinhlobo ezimbili eziyinhloko zemishini yokushisela i-Busbar diffusion. Enye i-resistance diffusion welding, eshisa ngokuqondile izinto eziyisisekelo ngokusebenzisa i-current high. Enye i-high-frequency diffusion welding, lapho i-graphite ishiselwa khona futhi idlulisela ukushisa kusisekelo. Zombili izindlela zishisisa izinto eziyisisekelo ekushiseni okuthile futhi, ngaphansi kwengcindezi ephezulu, zakha uxhumano lwesigaba esiqinile, ukufeza umphumela we-welding we-diffusion. Indlela yokushisa esetshenzisiwe incike ezintweni zeBusbar.

I-Resistance Diffusion Welding

I-Resistance diffusion welding isetshenziselwa ikakhulukazi ama-Busbars ethusi, njengoba ithusi linendawo ephezulu yokuncibilika kanye ne-conductivity. Ukuqinisekisa ukushisa okufanayo nokusheshisa inqubo, ama-electrode e-graphite asetshenziswa. Ama-electrode angaphezulu naphansi ahambisa amandla aphezulu ku-Busbar yethusi, ayishise ngokumelana nokuxhumana phakathi kwezingxenye eziningi ze-foil yethusi. Ama-electrode e-graphite ngokwawo nawo akhiqiza ukushisa ngenxa yokumelana kwawo okuphezulu. Lokhu kushisa okuhlangene kungakhuphula izinga lokushisa le-Copper Busbar libe ngaphezu kuka-600°C, lifinyelele ku-1300°C, okuvumela ukushisela okuphumelelayo kokusabalalisa ngaphansi kwengcindezi ephezulu.

I-High-Frequency Diffusion Welding

I-high-frequency diffusion welding ifanele ama-Busbars e-aluminium, ama-copper-nickel Busbars, ama-copper-aluminium Busbars, nama-Busbar ayinhlanganisela afana nezinhlanganisela zethusi nezingezona ezensimbi. Le ndlela isebenzisa ukufudumeza okungaqondile, okwenza kube ilungele ukushisela izinto eziyinkimbinkimbi. Ku-welding ye-high-frequency diffusion welding, i-graphite iyashiswa bese idlulisela ukushisa kusisekelo, amazinga okushisa afinyelela ku-1200 ° C. Ngaphansi kwengcindezi ephezulu, izinto zokwakha zakha uxhumano oluqinile.

I-Diffusion Welding of Different Busbar Materials

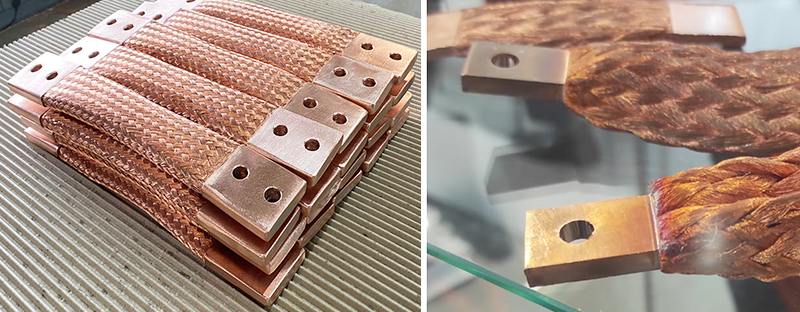

Izinto zethusi kulula ukuzishisela ngenxa yokuzinza kwama-oxide azo. Amabhasi e-copper ashubile, njengalawo asetshenziswa kumasistimu kagesi, adinga ukushiselwa kokusabalalisa ngenxa yokusebenza kahle kwawo okuphezulu. Lezi zingaba ugqinsi njengo-50mm nendawo yokushisela engu-200x200mm. Ama-Thinner Busbars, afana nalawo asetshenziswa ezimotweni zikagesi, ngokuvamile angu-3mm ubukhulu ngendawo yokushisela engu-25x50mm, angasebenzisa ukumelana noma ukushisela kwe-high-frequency diffusion.

Ama-Aluminium Busbars anenselelo enkulu ngenxa yephoyinti lokuncibilika le-aluminium (670°C) kanye nendawo yokuncibilika ephakeme kakhulu ye-aluminium oxide (2000°C). Okwe-aluminium, i-high-frequency diffusion welding ngokuvamile isetshenziswa, nempahla ehlanzwa kusengaphambili ukuze kukhishwe ama-oxide. Izinga lokushisa lokusabalalisa livame ukusetha ngaphansi kuka-600°C.

I-Copper-nickel Busbars iqukethe izendlalelo eziningi ze-copper foil ene-nickel foil coating yokuguga nokumelana nokugqwala. I-high-frequency diffusion welding ijwayele ukusetshenziselwa ukuphatha umehluko omkhulu wokumelana nogesi phakathi kwethusi ne-nickel. I-Composite Busbars, njengethusi ehlanganiswe ne-graphene, idinga i-welding yokusabalalisa imvamisa ephezulu ukuze ulawule ngokunembile inqubo yokushisisa futhi igweme ukulimaza izinto eziyisisekelo ngenkathi izuza ukusakazeka.

Izindlela Zokucindezela ku-Busbar Diffusion WeldingUmshini

I-Diffusion welding idinga ingcindezi ephezulu, engasetshenziswa kusetshenziswa ama-air-liquid booster, ama-hydraulic systems, noma ama-servo systems. Izindlela zendabuko ngokuvamile zisebenzisa amasistimu we-hydraulic okukhiphayo okuzinzile namandla aphezulu. Namuhla, ukucindezela kwe-servo kuya ngokuya kuduma ngokulawula kwayo ingcindezi okunembile kanye nokugudluka okulungisekayo, okuqinisekisa ukunemba okuphezulu kobukhulu bomkhiqizo oshiselwe.

Isiphetho

Lesi sithombe esifushane se-Busbar diffusion welding. Uma ufuna indlela yokushisela efanele yamaBusbars, lesi sihloko kufanele sinikeze izimpendulo. Ngokuthuthuka okuqhubekayo kobuchwepheshe bokushisela, kwamukelwa amasu amasha ukuze kuhlangatshezwane nezidingo zomphakathi wanamuhla.

Isikhathi sokuthumela: Sep-20-2024