Ukuhlanganisa okungaphelele, ngokuvamile okwaziwa ngokuthi “i-cold weld” noma “ukuntuleka kokuhlanganisa,” kuyinkinga ebucayi engenzeka phakathi nezinqubo zokushisela amabala kusetshenziswa.imishini yokushisela amabala. Kubhekiselwa esimweni lapho insimbi encibilikisiwe ihluleka ukuhlangana ngokugcwele nezinto eziyisisekelo, okuholela ekuhlanganyeleni okushisela okubuthakathaka nokungathembeki. Le ndatshana ihlose ukuhlola izici ezahlukahlukene ezingaholela ekuhlanganisweni okungapheleleukushisela indawo.

Welding Current

I-Welding yamanje ingenye yemingcele ebaluleke kakhulu ku-inqubo Welding, futhi inomphumela wokuphindaphinda ekushiseni okukhiqizwa ngesikhathi sokushisela. I-welding current enganele ingesinye sezizathu eziyinhloko zokungahlanganisi. Uma i-welding current iphansi kakhulu, ingase ingakhiqizi ukushisa okwanele ukuze incibilike ngokugcwele i-substrate. Ngenxa yalokho, insimbi encibilikisiwe ayikwazi ukungena futhi ixhume kahle, okuholela ekuhlanganiseni okungaphelele endaweni yokushisela.

I-Electrode Pressure enganele

Amandla kagesi anganele nawo angaholela ekuhlanganiseni okungaphelele. Ingcindezi kagesi isetshenziswa ku-workpiece ukuze kuqinisekiswe ukuthintana okulungile nokungena ngesikhathi sokushisela. Uma amandla kagesi ephansi kakhulu, indawo yokuxhumana phakathi kwe-workpiece kanye ne-workpiece incane, lapho i-welding, ukunyakaza kwe-athomu ye-solder joint ngeke kwanele, ukuze amalunga amabili e-solder cishe awahlanganiswe ngokugcwele.

Ukuqondanisa kwe-Electrode Akulungile

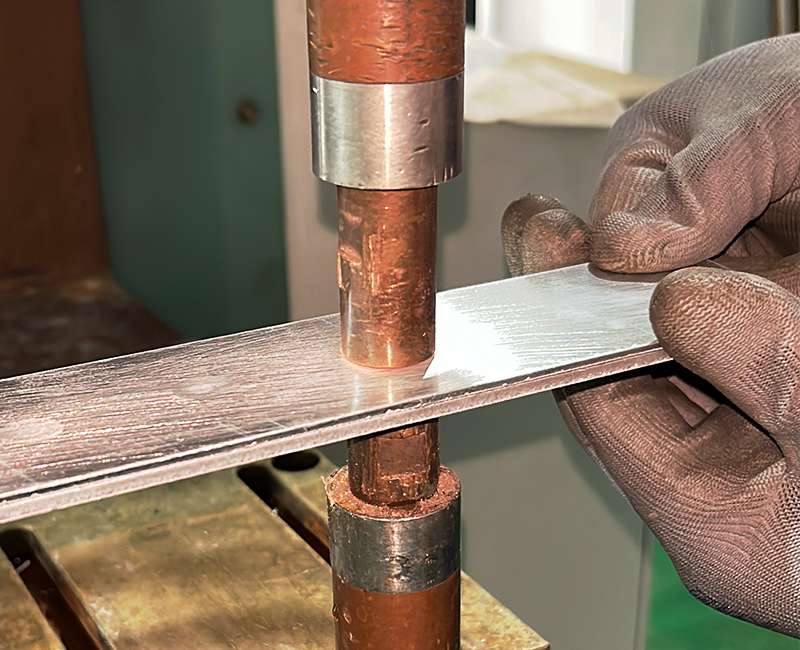

Ukuqondanisa okungalungile kwama-electrode kungaholela ekusabalaliseni ukushisa okungalingani, okuholela ekuhlanganiseni okungaphelele. Lapho ama-electrode engaqondani, ukushisa okukhiqizwa ngesikhathi senqubo yokushisela kungase kungasatshalaliswa ngokulinganayo kuyo yonke indawo yokushisela. Lokhu kusatshalaliswa kokushisa okungalingani kungaholela ekuhlanganiseni okungaphelele ezindaweni zendawo. Ngakho-ke, ngaphambi kokuba umsebenzi wokushisela uqale, qiniseka ukuthi uhlola ukuthi ama-electrode aphezulu naphansi anembile yini, uma engahambelani, kuyadingeka ukuwaqondanisa ngethuluzi.

I-Workpiece Surface Ukungcola Noma I-Oxidation

Ukungcoliswa noma ukufakwa kwe-oxidation kwendawo yokusebenza kungaphazamisa ukuhlangana okuvamile ngesikhathi sokushisela indawo. Ukungcola, okufana namafutha, ukungcola, noma okokunamathela, kusebenza njengesithiyo phakathi kwensimbi encibilikisiwe ne-substrate, evimbela ukuncibilika. Ngokufanayo, i-surface oxidation ingakha ungqimba lwe-oxide oluvimbela ukuhlangana okufanele nokuhlangana. Isibonelo, uma ufuna ukushisela i-fin eyenziwe yi-isiphethoithubhuumshiniku-tube, uma ubuso be-tube bugqwalile, i-welding kufanele ingabi yi-fusion, ukuze i-joint welded ingazinzi futhi ithinte ikhwalithi yomkhiqizo.

Isikhathi Esifushane Sokushisela

Isikhathi sokushisela esinganele sivimbela insimbi encibilikisiwe ukuthi ingagelezi ngokwanele futhi ihlanganiswe nezinto eziyisisekelo. Uma isikhathi se-welding sifushane kakhulu, ukuthintana kwensimbi akuhlanganisiwe ngokugcwele ngaphambi kokuphela kokukhishwa, futhi le nhlanganisela enganele izoholela ekushiseni okubuthakathaka nokungathembeki.

Ukuqonda izici eziholela ekuhlanganiseni kwe-spot welding okungaphelele kubalulekile ekuqinisekiseni ukushisela kwekhwalithi ephezulu. Ngokuxazulula izinkinga zokunganele kwe-welding yamanje, amandla kagesi anganele, ukulungiswa kwe-electrode okungalungile, ukungcoliswa kwendawo noma i-oxidation, kanye nesikhathi esinganele sokufaka i-welding, unganciphisa ukuvela kokuhlanganiswa okungaphelele lapho umsebenzi we-welding, ukuze izinga lokushisela liphelele lingathuthukiswa kakhulu.

Isikhathi sokuthumela: Sep-24-2024