I-Aluminium isetshenziswe emikhakheni ehlukahlukene ngenxa yesisindo sayo esilula, ukumelana nokugqwala, ukuqhutshwa kahle kukagesi nezinye izici, ngokukhuphuka kwamandla amasha, ukusetshenziswa kwe-aluminium kuye kwaqiniswa, futhi uxhumano lwe-aluminium ngaphezu kwe-riveting, ukubopha ukushisela, ukuze kuxhunywe ipuleti le-aluminiumukumelana nokushiselakuyinqubo ebalulekile, izimo zohlelo lokusebenza ngaphezu kwezicelo ezijwayelekile zezimboni, Isetshenziswa kabanzi ezimotweni zamandla amasha, i-aerospace kanye neminye imikhakha.

Izimiso zeAi-aluminiumWelding

Izinzuzo zokumelana ne-aluminium plateukushisela indawozisobala, ngaphandle kokwengeza izinto ezisizayo, kuphela ngokuncibilika kwensimbi okuyisisekelo kungakha i-solder eqinile.I-Aluminiumemoyeni kuvame ukuba nongqimba lwefilimu ye-oxide, indawo yokuncibilika ye-aluminium ingu-660 degrees Celsius, kanti ifilimu ye-oxide iyi-aluminium oxide, indawo yayo yokuncibilika icishe ibe ngama-degree angama-2000, bese incibilikisa isisekelo ukuze kwakhiwe umnyombo kuqala ukuphula ungqimba lwe-oxide. , okuphinde kube inqubo yokushisela indawo ye-aluminium kubhekwa njengesizathu esinzima kakhulu.

UkushiselaEquipmentSukhetho

Ukukhethwa kwepuleti le-aluminiumumshini wokushisela indawo, i-intermediate frequency inverter DC amandla kagesi ngenxa yokuphuma kwawo kwamanje yi-DC, esebenza kahle kakhulu ekushiseni okushisayo, ngakho-ke iyinketho yokuqala yokushisela ipuleti le-aluminium. Ugesi ojwayelekile wezigaba ezintathu wokulungisa wesibili uyisilungisi se-half-wave, amandla okugcina amandla e-capacitive nakuba okukhiphayo kuyi-DC kodwa isikhathi sifushane kakhulu, ngakho-ke ukusebenza kwakho okuphelele akukuhle njenge-intermediate frequency inverter DC spot welder, lezi. Izinsiza zikagesi zinezinhlelo zokusebenza ekuqaleni, isimo sohlelo lwesikhathi esizayo sizoncipha.

AmaphuzuTo NothiWisikhukhukaziAi-aluminiumSibhodweWelding

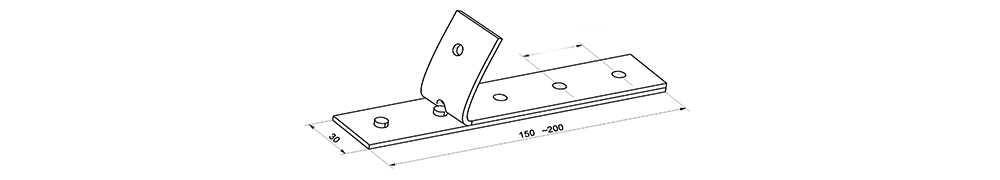

I-aluminium plate spot welding process, i-aluminium plate conductivity kanye ne-thermal conductivity ratio iphezulu, ngakho-ke isidingo sesikhathi esikhulu sokushisela samanje nesifanele, esidinga ukunakwa kula maphuzu alandelayo:

1. Amandla ezinto zokusebenza kufanele abe makhulu ngokwanele ukuqinisekisa ukuthi okukhiphayo kwamanje kungaba okukhulu ngesikhathi esifushane, ngokuvamile izikhathi ezingu-2-3 zamanje ze-carbon steel spot welding;

2. I-electrode idinga ukupholisa amanzi aqinile, futhi ukushisa kungasuswa ngokushesha ngemva kokushisela;

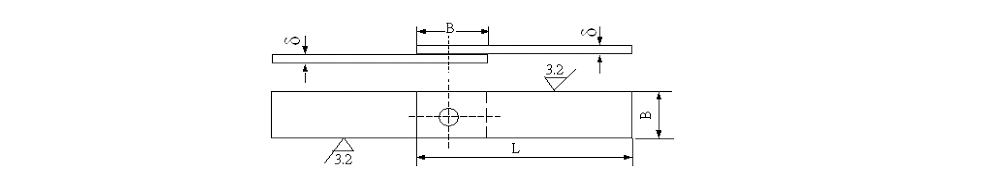

3. Ububanzi obuyindilinga bomkhawulo ongaphambili we-electrode kufanele bufaniswe, futhi ukujiya kwepuleti okuhlukile kufanele kube nezimbulunga ezihlukene, futhi isimiso akufanele sibe ngaphansi kuka-SR25;

4. Ububanzi be-electrode kufanele buhambisane nobukhulu bepuleti, futhi ububanzi be-electrode obungaphansi kuka-1.0MM wepuleti bungu-¢13; Ukujiya kweshidi 1.0-1.5 Ububanzi be-Electrode ngu-¢16; Ukujiya kweshidi 1.5-2.0 Ububanzi be-Electrode ngu-¢20; Ugqinsi lwepuleti ngaphezu kobubanzi be-electrode engu-2.0 abukho ngaphansi kuka-¢25;

5. Izinto ze-electrode zenziweingxubevange yethusinge-conductivity ephezulu noma ithusi eliqinile, futhi i-conductivity ayikho ngaphansi kwe-80% IACS;

6. Ukuze kuhlangatshezwane namajoyinti e-solder ekhwalithi ephezulu, ingaphezulu lepuleti le-aluminium kufanele likhishwe i-deoxidized, pickling noma i-polishing, futhi ukumelana kwendawo ye-A-level ye-Aviation yemikhiqizo yezempi / yezempi kufanele ilawulwe ku-50 microohm-100 microohm;

UkushiselaQukuphilaIukuhlola

I-aluminium plate spot welding ngemva kokuhlolwa ikakhulukazi ukuhlolwa okungabhubhisi kanye nokutholwa komonakalo izigaba ezimbili, ezingabhubhisi ikakhulukazi ngokubonwa, i-X-ray kanye nokutholwa kwe-ultrasonic, ukutholwa komonakalo ikakhulukazi ukwelula, izikhathi eziphansi nokunye ukutholwa, izindlela ezithile zokubona zimi kanje. :

1. Ukuhlolwa kokubukeka, okuhlanganisa ukuma kwejoyinti le-solder, umbala ohlangene we-solder, ukujula kokuhlehlisa, njll.;

2. Ukutholwa kwe-X-ray, ukutholwa kwefilimu yobubanzi be-weld core, kungakhathaliseki ukuthi i-weld core iyaqhekeka, i-shrinkage nezinye iziphambeko;

3. Ukutholwa kwamandla aphansi, izikhathi eziyi-15-25 ngemuva kokugqwala kocezu lwamalunga e-solder, ukuthola ukufinyeleleka kwe-welding, ukukhubazeka kokushisela, njll.;

4. Ukuhlolwa kwe-tensile, amandla ahlangene wokuhlola we-solder;

5. Ukuhlolwa kokukhumula, ukuhlubula noma ukudabula amalunga e-solder, ikakhulukazi asetshenziselwa ukutholwa kwamandla esizeni kanye nokuqinisekiswa kobubanzi bomnyombo.

6. Ukutholwa kwe-Ultrasonic, ngokuthuthukiswa kobuchwepheshe bokutholwa kwe-ultrasonic, ukusetshenziswa kokutholwa kwe-spot welding kuyaqhubeka nokuqina, ngokuqhathanisa i-waveform ebonisiwe, kanye nokuvuthwa kobuchwepheshe be-imaging yedijithali, ukutholwa kwe-polycrystalline head ultrasonic kuzoba yisinqumo esihle ukuhlolwa okungabhubhisi kwe-aluminium spot welding.

Isifinyezo

Ngokusetshenziswa okuvuthiwe kweUmshini wokushisela we-MFDC, kanye nokuthuthukiswa kwenqubo yokushisela kanye nezindlela zokubona, umkhawulo we-aluminium plate spot welding izoba phansi futhi ibe phansi, futhi izophinde ikhuthaze ukushisela i-aluminium plate spot ku-industrial lightweight, kanye namandla amasha, i-aerospace nokunye okubanzi. esetshenzisiwe.

Isikhathi sokuthumela: Aug-07-2024