I-Metal sheet welding iyingxenye ebalulekile yenqubo yokukhiqiza yemikhiqizo ehlukahlukene yensimbi. I-Spot welding isetshenziswa kabanzi embonini yokukhiqiza izimoto, imboni yehardware yemishini yasendlini, kanye nemboni yebhokisi lensimbi. Ubuchwepheshe besimanje budinga ikhwalithi ephezulu yokushisela. Kulesi sihloko, sizochaza inqubo ye-welding ngokuningiliziwe futhi sixoxe ngezinzuzo zeukushisela indawoembonini yezimoto.

Yini Spot Welding

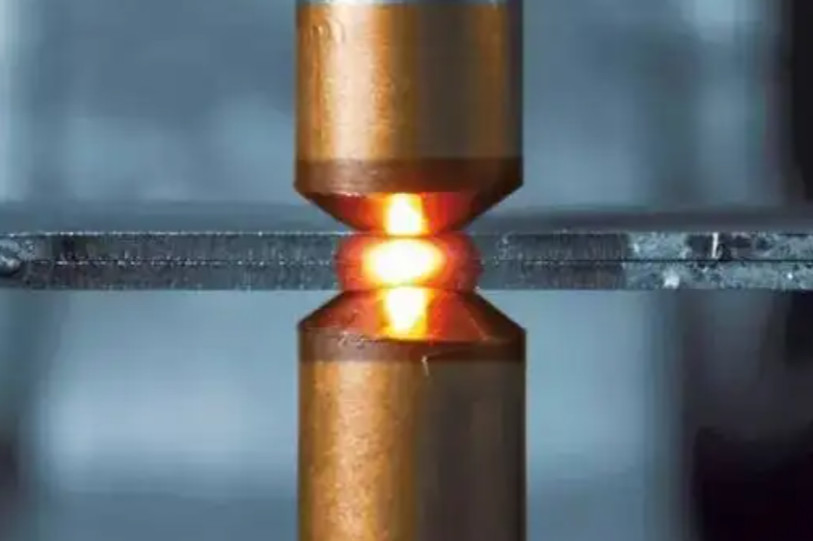

Spot welding uhloboukumelana nokushisela. Kuhilela ukubeka ama-workpiece amabili phakathi kwama-electrode angaphezulu nangaphansi, ukuwashisisa ngomsinga kagesi, nokusebenzisa ingcindezi ukuze udale isimo sepulasitiki endaweni yokuxhumana yezinto zokusebenza, okuzivumela ukuthi zihlangane. Isimiso saso silula: ngokuqhuba ugesi ngokusebenzisa ama-electrode amabili ethusi, ukumelana kwandisa izinga lokushisa kwezinto zokusebenza, okubangela ukuba zincibilike futhi zihlangane ndawonye. Yingakho kubuye kubizwe nge-resistance welding. Uma kuqhathaniswa nezinyeizinqubo zokushisela, ukushisela indawo akudingi ukwengeza izinto zokushisela, futhi ukusebenza kulula.

Indlela yokubona i-Weld?

1: Ukuhlanza Indawo Yokusebenzela

Spot Welding Izinto Ezivamile

I-Aluminium: I-Aluminium ivame kakhulu ekushiseleni indawo, ikakhulukazi embonini yezimoto, lapho izici zayo ezingasindi zingangena esikhundleni sezakhiwo eziqinile. Kodwa-ke, i-aluminium yokushisela inselele kakhulu ngenxa ye-conductivity yayo ephezulu, edinga cishe kabili inani lamanje lezinto ezijwayelekile. Ngakho-ke, lapho ushisela i-aluminium, kufanele ukhethe imishini enamandla amakhulu.

Insimbi: Insimbi yinto ejwayeleke kakhulu ekushiseleni indawo. Kuyinto eqinile, futhi izingxenye eziningi zezimoto zisebenzisa insimbi. I-Spot welding ngokuvamile isetshenziselwa ukushisela imizimba yemoto kanye nezingxenye zamantongomane aqinile.

Ithusi: I-Spot welding copper idinga amasu akhethekile. I-Copper ine-conductivity ephezulu yokushisa kanye nogesi, okwenza ijwayele ukunamathela kuma-electrode. Ngakho-ke, sikhetha i-tungsten noma i-molybdenum electrode. Ngesikhathi sokushisela, i-brazing material idinga ukungezwa phakathi kwezinto ezimbili zokusebenza, ngakho-ke i-copper brazing ivame ukusetshenziswa.

Insimbi engaphekiwe: Insimbi yokushisela insimbi inzima kakhulu kunensimbi yokushisela, edinga amandla amanje aphezulu. Iphuzu elincibilikayo le-galvanized coating liphansi kunelensimbi, ngakho-ke kulula ukuchichima futhi wenze ama-splashes ngesikhathi sokushisela.

I-Workpiece Surface Cleaning

Ngaphambi kokushisela, kubalulekile ukubheka ukuthi izinto zokusebenza zinokugqwala yini noma zine-oxidation. Uma benza, iziqephu zokusebenza zidinga ukwelashwa. Ungasebenzisa i-sandpaper noma i-grinder ukwenza ubuso bushelelezi. Uma kungenjalo, kuzoba ne-splatter eminingi, engathinta ikhwalithi yokushisela.

2: Ukucabangela Okuguquguqukayo Oku-4 Ngaphambi Kokushisela Nokusetha Amapharamitha

Ingcindezi

Ukukhetha ingcindezi efanele kubalulekile. Uma ingcindezi ye-electrode iphezulu kakhulu noma iphansi kakhulu, ingenza buthaka amandla e-weld futhi ikhulise ukuhlakazeka kwayo. Lapho ushisela, kubalulekile ukucabangela izici ze-workpiece lapho ubeka ingcindezi.

Isikhathi sokushisela

Ukusetha isikhathi sokushisela esifanelekile kubalulekile. Uma isikhathi sokushisela sisifushane kakhulu, i-workpiece ingase ingancibiliki ngokwanele ukuze ihlangabezane nezidingo zokushisela. Ngakolunye uhlangothi, uma isikhathi sokushisela siside kakhulu, i-workpiece ijwayele ukuguqulwa, okuholela kumamaki ama-weld amakhulu.

I-Welding Yamanje

I-welding current kanye nesikhathi ziyahambisana, kodwa futhi zinemikhawulo yazo. Ukuthola ibhalansi efanele phakathi kokubili kuyisihluthulelo sokukhiqiza ama-welds aphelele.

3: Spot Welding Machine

Izinto ezidingekayo zokushisela amabala yi-umshini wokushisela indawo, eza ngamamodeli ahlukene. Ukukhetha umshini wokushisela indawo efanele kuncike ezicini ze-workpiece kanye nezidingo zokushisela. Isibonelo, uma ufuna ukushisela ndawonye amapuleti amabili ensimbi engagqwali angu-2mm ukuze uzuze amandla adingekayo wempahla yomzali, uzodinga ukukhetha umshini wokushisela indawo onamandla amakhulu. Umshini wokushisela indawo ojwayelekile one-130KVA ungakufeza lokhu. Kodwa-ke, uma udinga ukushisela amapuleti angu-2mm awugqinsi we-aluminium, uzodinga umshini wokushisela onamabala ongu-260KVA.

4: Beka I-Workpiece Phakathi Kwama-Electrodes Bese Uqala Ukushisela

Uma usukhethile umshini wokushisela indawo ofanele, sekuyisikhathi sokuqala ukushisela. Ngemva kokuxhuma ukunikezwa kwamandla nokulungisa imingcele, beka i-workpiece elungiselelwe phakathi kokubilii-electrode cap. Cindezela inkinobho yokunyathela unyawo, futhi ama-electrode azocindezela phansi, ashise futhi acindezele ama-workpieces, ngaleyo ndlela axhumanise amaphuzu okuxhumana ezingxenye zokusebenza ezimbili ndawonye.

5: I-Peel Test Ngemva Kokushisela

Ngemva kokushisela i-workpiece, kunzima ukuhlola amandla e-weld ngeso lenyama lodwa. Yilapho udinga ukusebenzisa amathuluzi ukuze uhlole amandla e-weld. Ukuhlola i-peel kuyindlela enhle. Ngesikhathi sokuhlolwa kwamapeel, bheka amandla amakhulu okuqina okufinyelelwe lapho uxebula ucezu lokusebenza. Amanye ama-workpiece anezidingo ezithile zalelivelu ukuze kuthathwe ukuthi ukushisela kwamukelekile.

Izinzuzo Ze-Spot Welding For Automotive Industry

Amalunga Aqinile Futhi Ahlala Isikhathi Eside

Izingxenye ezishiselwe kusetshenziswa ukushisela ukumelana zenza amalunga aqinile futhi aqinile. Imikhiqizo eyenziwe ngale ndlela iqinile futhi izinzile, okubalulekile embonini yezimoto. Isibonelo, uma inati lingashiselwe ngokuphephile, lingaholela ezingozini emgwaqeni. Ukunemba nokuthembeka kubaluleke kakhulu emkhakheni wezimoto, lapho ngisho nephutha elincane lingamukeleki. Ngakho-ke, i-resistance welding idlala indima ebalulekile ekuqinisekiseni ukuthi la mazinga ayahlangatshezwa.

Ukufana Kwamalunga

Ezingxenyeni zezimoto zokushisela, akubalulekile nje kuphela ukuthi izinto zokushisela zibe namandla kodwa futhi nemikhiqizo eshiselwe ibukeke ibukeka kahle. I-Resistance welding ingafinyelela le mfuneko. Ikakhulukazi ekushiseleni umzimba wemoto, yonke indawo ye-weld kufanele ingabonakali, njengoba ithinta ukucubungula okulandelayo kanye nokubukeka okuphelele kwemoto.

Ukuhlanganisa Izinto Ezingafani

I-Resistance welding nayo ifaneleka ukushisela izinto ezingafani. Embonini yezimoto, kunezingxenye lapho izinsimbi ezahlukene zidinga ukuhlanganiswa ndawonye. Yilapho i-resistance welding isiza khona, njengoba ingajoyina izinto ezingafani, njengensimbi ne-aluminium.

Isivinini sokushisela

I-Resistance welding ayidingi i-filler wire. Iyashesha ukushisela izingxenye ezincane. Embonini yezimoto, lapho iningi lezinto ezincane ezishiselwe khona, inqubo iyashesha futhi i-othomathikhi kalula, yonga abasebenzi futhi ikhulisa ukusebenza kahle kokushisela.

Ukuphindaphinda

Ngenxa yokufaneleka kwayo kwemikhiqizo ephindaphindwayo yokushisela, ukushisela ukumelana kungadinga ukulungiswa kwepharamitha kanye nemishini lapho ushintshela ekucacisweni okuhlukile. Ngakho-ke, ilungele kakhulu ukushisela imikhiqizo enevolumu ephezulu. Izingxenye zezimoto, ngenxa yalesi sici, zithola i-resistance welding efaneleka ngokukhethekile embonini yezimoto.

I-Resistance welding isetshenziswa kabanzi emikhakheni yezimboni yanamuhla. Ubuchwepheshe bayo bubuyekezwa ngokuqhubekayo ukuze buvumelane nokuthuthukiswa kwezimboni, buqhubekela ku-automation. Ukuze ufunde kabanzi mayelana ne-resistance welding, sicela ulandele izibuyekezo zethu.

I-FAQ:

1,Iyiphi indlela yokushisela okufanele ngiyisebenzise ukushisela isigubhu sikawoyela wensimbi engagqwali okudingeka sivalwe ngokuqinile?

Ngezidingo ezingenamoya, ungasebenzisa i-seam welding, aumthungo welderengakwenza.

2,Hlobo luni lomshini wokushisela ovame ukusetshenziselwa izingxenye zomzimba wemoto?

Imizimba yezimoto ivamise ukusetshenziswaindawoisibhamu sokushisela, eziguquguqukayo futhi kulula ukuzenzela.

3,Iyiphi i-power spot welder edingekayo ukuze ushise insimbi engagqwali engu-2mm ewugqinsi?

I-weld yendawo engu-130kVAumshiniizosebenza kahle.

4,Ngilishisela kanjani i-M8 nut epuleti lensimbi le-carbon engu-2mm?

Ungasebenzisa i-projection weldumshini.

5,Ngiwalungisa kanjani amapharamitha we-spot welding?

Lungisa amapharamitha asuselwa ekucacisweni kocezu lwakho lokusebenza kanye nezidingo zokushisela.

6,Kanjanitoukushisela indawo ngaphandle komshini wokushisela?

Ungasebenzisa irobhothi ukulayisha okuzenzakalelayo kanye nokushisela.

7,Kanjanitoweld aluminium?

I-Aluminium inephuzu lokuncibilika eliphansi, ngakho udinga amandla aphezulu. AI-MFDCi-spot welder ingasetshenziswa.

Isikhathi sokuthumela: May-30-2024