I-Direct current (DC) welding kanye ne-alternating current (AC) welding ezimbili ezivame ukusetshenziswaizinqubo zokushisela, futhi ngayinye inezici zayo. Kulesi sihloko, sizohlaziya ukuthi uyini umehluko phakathi kwe-DC welding kanye ne-AC welding emkhakheni weukumelana nokushisela, futhi yikuphi ukushisela okuzuzisa kakhulu? Lokhu kuzokusiza ukuthi ukhethe phakathi kwakho kokubili.

Izimiso Zokusebenza:

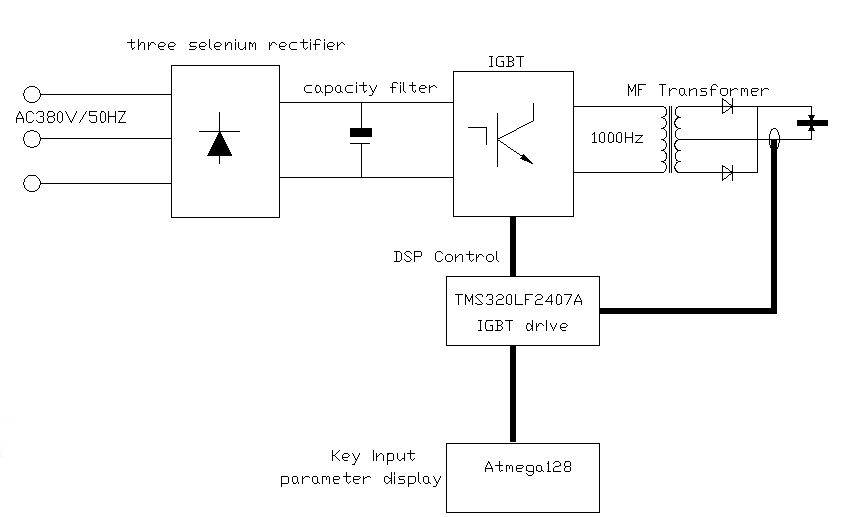

MFDC/Inverter Welding Machine:

Okokuqala,isigaba sesithathuI-voltage ye-AC idlula kwizilungisi ukuze zihlungwe.

Okwesibili,I-IGBTamaswishi aguqula okwamanje abe i-mid-frequency current engu-1000 Hz futhi ayidlulisele ku-i-welding transformer.

Ekugcineni, ama-diode okulungisa amandla aphezulu akhipha i-welding current njenge-stable direct current (DC).

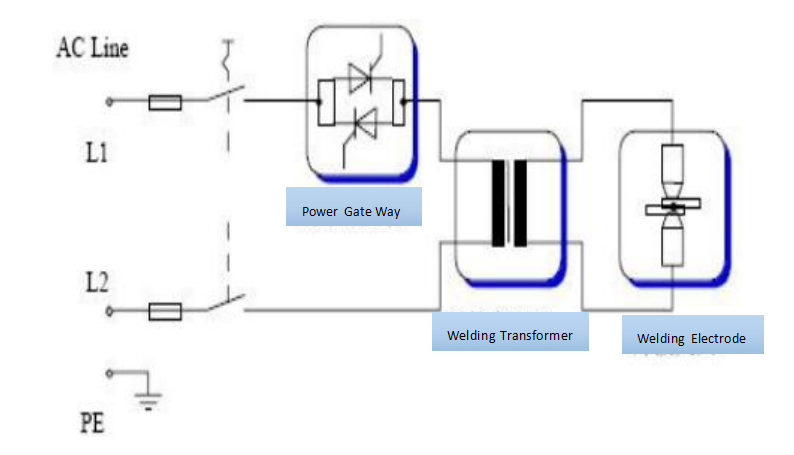

Umshini Wokushisela we-AC:

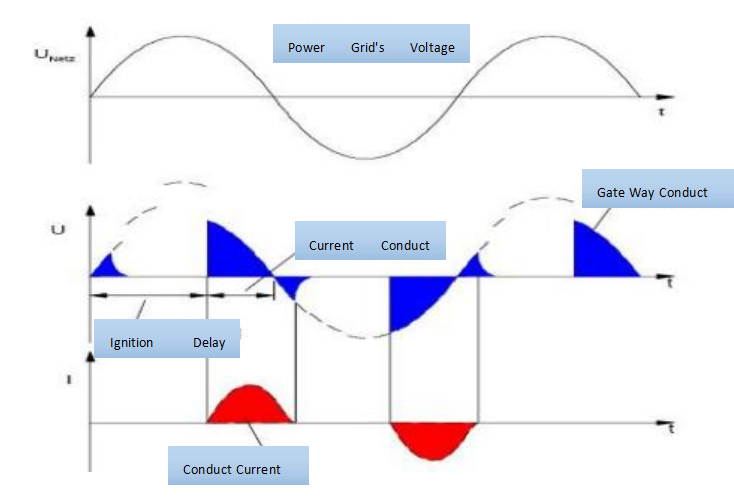

Okokufaka kwamandla yi-AC, okuthi, ngemva kokudlula ekushintsheni kwamandla, ingene kumjikelezo oyinhloko nokulawula.

I-transformer yehlisa i-high-voltage AC iye ku-AC enevoltage ephansi elungele ukushiselwa. I-AC yamanje ishintshashintsha phakathi kokuphozithivu nokubi, okukhiqiza ukushisa njengoba kudlula endaweni yokushisela kanye nocezu lokusebenza, ngaleyo ndlela incibilikisa impahla yokushisela futhi kuzuzwe ukushisela.

Uyini umehluko phakathi kwe-DC welding ne-AC welding?

Ukuzinza

I-DC welding ingenye yemikhiqizo yokushisela ehlonishwa emhlabeni wonke enezinga eliphezulu eliqinile. Imingcele yenqubo yokushisela inobungane, i-ADAPTS yesibili yamanje kuya kububanzi obubanzi, futhi igcina ngempela yamanje njalo, enethuba elibanzi lesicelo kune-AC welding.

I-DC welding current ilungiswa ngenani lezikhathi eziyi-1000 ngomzuzwana, ifinyelela ukunemba kwe-millisecond, ephakeme izikhathi ezingaphezu kwezingu-20 kunokunemba kwamashisela endabuko e-AC.

I-DC welding ayithinteki ngokuma kanye nempahla ye-workpiece, isusa ukulahlekelwa kwe-inductance. Umshini wokushisela we-AC kulula ukuwohloka kwe-welding noma ukungaqini kahle ngenxa yezinguquko ekubunjweni kwezinto zokusebenza.

I-Weld Splash

Ukunikezwa kwamandla kagesi kwe-DC kukhipha i-waveform encane kakhulu ukugwema ukushaqeka okukhulu kwamanje futhi kunciphise ukuchaphazeka ngesikhathi sokushisela. Kodwa i-AC Welding inqubo yokushisela izokhiqiza i-spatter eningi, ithinte ikhwalithi yemikhiqizo yokushisela.

Ukusebenza kahle kwe-Welding

Isici samandla okushisela womshini wokushisela we-DC singaphezu kuka-98%, kanti amandla okushisela omshini wokushisela we-AC cishe angama-60%, okubonisa ukuthi ukusebenza kahle kwe-DC welding kuphakeme kakhulu kune-AC.

Izindleko

Ngenxa yokuthi inani lokuqala le-DC welding current landa kakhulu, isikhathi se-welding sangempela sifinyezwa ngaphezu kuka-20%, futhi izindleko zesikhathi zigcinwa kakhulu.

Kodwa-ke, ezindlekweni zomshini wokushisela, umshini wokushisela we-AC ubusa kakhulu, futhi intengo yawo ingaba nje jikelele noma ngaphansi komshini we-DC. Uma unesabelomali esilinganiselwe sokuthenga umshini wokushisela, khona-ke umshini we-AC nawo uyisinqumo esihle.

Ukongiwa Amandla

Izidingo zokunikezwa kwamandla embonini ziphansi, cishe 2/3 kuphela we-AC welder, noma ngabe i-voltage yokunikezwa kwamandla ishintshashintsha, i-welder ye-DC isengakwazi ukulawula ngokunembile amandla okushisela. Ngakho-ke, ukusetshenziswa kwamandla omshini wokushisela we-DC kuncishiswe kakhulu, futhi ngaphezu kuka-40% ukonga amandla kufinyelelwa.

Ukuvikelwa Kwemvelo

I-DC welding iyindlela yokushisela eluhlaza eqeda ukungcoliswa kwamandla kagesi, ayidingi ukunikezwa kwamandla okuhlukile, futhi ingasetshenziswa nesistimu yokulawula ukushisela i-robot. I-Ac welding inomthelela omkhulu kugridi yamandla, futhi kulula ukungcolisa ukunikezwa kwamandla.

Isifinyezo

Kafushane, i-DC welding iphakeme kune-AC welding ezicini eziningi. Uma unesabelomali esanele, kufanele ukhethe i-DC welding. Ngaphezu kwalokho, uma udinga ukushisela imikhiqizo enezidingo zekhwalithi ephezulu, umshini we-DC nawo uyisinqumo sakho esingcono kakhulu.

Isikhathi sokuthumela: Jul-30-2024