I-Sheet Metal welding isetshenziswa ezimbonini eziningi. Noma nini lapho udinga ukujoyina izingxenye zensimbi, uzocabangela ukuthi ungazishisela kanjani. Ubuchwepheshe bokushisela sebuthuthuke kakhulu, futhi ukukhetha indlela yokushisela efanele kungenza umsebenzi wakho ube lula futhi usebenze kahle. Lesi sihloko sizokuqondisa ekuqondeni ukushisela kwensimbi yeshidi futhi sikusize uthole indlela efanele yokushisela.

Iyini I-Sheet Metal Welding?

Ishidi metal weldingiwubuchwepheshe bokucutshungulwa kwezinto, okubhekisela ekuxhumekeni kweezimbilinoma izingxenye zensimbi ezihlukene zibe yinye ngendlela ethile. Ngokuthuthuka kobuchwepheshe bezimboni, ubuchwepheshe be-welding busetshenziswa kabanzi, okuyinqubo ebalulekile ekucutshungulweni kwensimbi embonini yokukhiqiza.

Yiziphi izindlela ze-metal welding?

Kunezinhlobo eziningi zezindlela zokushisela insimbi, ngokusho kwesimo kanye nezici zenqubo yensimbi enqubweni yokushisela, izindlela zokushisela insimbi zihlukaniswa kakhulu zibe izigaba ezintathu: i-fusion welding, i-pressure welding kanye ne-brazing.

I-Fusion Welding

I-Fusion welding iyindlela yokuhlanganisa izingxenye zensimbi ngokuzifudumeza nokuzincibilikisa ndawonye. Le ndlela ayidingi ingcindezi. Ukuxhumana kwezingxenye zokusebenza ezimbili kuyashisisa, okwenza insimbi ikhiqize amandla abalulekile e-athomu, yakhe isimo se-liquid endaweni eshisayo. Ama-athomu ensimbi wezinto ezimbili zokusebenza ahlakazeka ngokugcwele futhi ahlangane. Lapho insimbi encibilikisiwe iphola, yakha ilunga eliqinile elishiselwe.

Amasu okushisela ama-fusion ajwayelekile afaka i-arc welding, i-gas welding, ne-laser welding.

I-Arc Welding

I-arc weldinginikwa amandla umthombo kagesi ophuma phakathi kwe-electrode kanye nezingxenye zokusebenza ezimbili ukwenza i-arc. Le arc iguqulela ekushiseni, incibilikisa i-electrode nezinto zokusebenza, ihlanganise izinsimbi ndawonye. Phakathi nenqubo yokushisela, i-voltage ephansi kanye namandla aphezulu kukhiqiza amazinga okushisa aphezulu nokukhanya okukhulu, kushise i-electrode kanye nezinto zokusebenza ukuze kwakhiwe ichibi elincibilikisiwe elipholisa ukwenza i-weld.

Le ndlela yokushisela inezinhlobonhlobo zezinhlelo zokusebenza futhi ingasetshenziswa ukushisela izinsimbi ezihlukahlukene njengensimbi engagqwali, i-aluminium, ithusi, nensimbi enekhabhoni ephezulu. Ngenxa yokuthi imishini yokushisela i-arc iyaphatheka futhi kulula ukuyisebenzisa, isetshenziswa kakhulu ezimbonini ezifana nokukhiqiza imishini, ukwakhiwa, kanye nokwakha imikhumbi. Isibonelo, isetshenziselwa ukuxhumeka kwe-rebar ekwakheni. Ukwengeza, i-arc welding ivame ukusetshenziswa ekulungiseni imishini nasekulungiseni umzila wesitimela.

Ukushisela i-arc ngokuvamile kudinga umshini wokushisela we-arc, izinduku zokushisela, nesihlangu sobuso. Kuyindlela yokushisela engabizi kakhulu futhi esetshenziswa kabanzi. Kodwa-ke, ngenxa yobunzima bayo bezobuchwepheshe, ikhwalithi ye-weld incike kakhulu ezingeni lekhono le-welder.

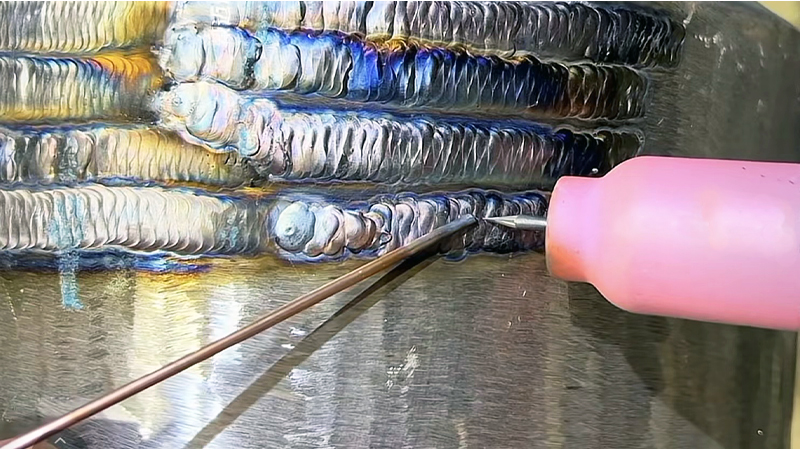

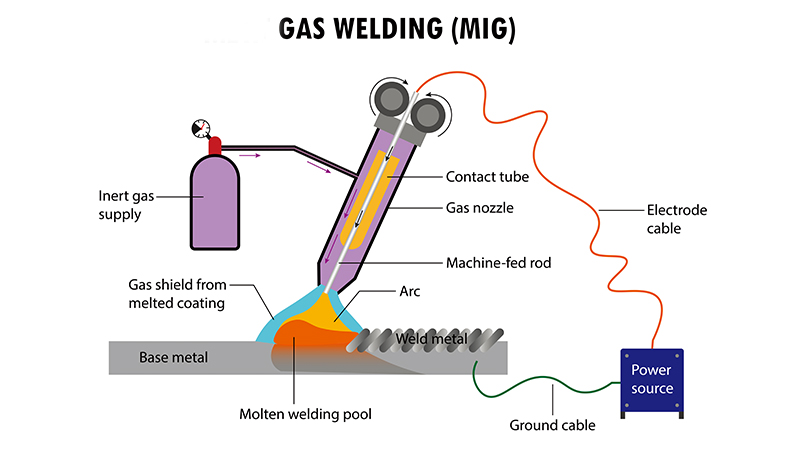

Ukushisela Igesi

Ukushisela igesiisebenzisa izinhlobo ezimbili zegesi: i-fuel gas kanye ne-oxidizing gas. Ukushiswa kwaleli gesi kudala ukushisa, okusetshenziselwa ukuncibilikisa izinto zensimbi kanye nenduku yokushisela ezilokhu ziphakelwa phakathi kwezinto ezimbili zokusebenza, kuphothula ukuxhumana kwensimbi.

Ukushisela igesi kuvame ukusetshenziselwa ukushisela izinsimbi njengensimbi, i-aluminium, nethusi. Inikeza izinzuzo ezifana nokuguquguquka ekusetshenzisweni, akukho mingcele endaweni yokusebenza, nokusebenza okulula. Ukwengeza, awudingi ugesi, okwenza usetshenziswe kabanzi emisebenzini yangaphandle nasezindaweni zokwakha zokuxhunywa kwensimbi. Uma udinga ukulungisa ipayipi lensimbi, ukushisela igesi kuyisinqumo esihle kakhulu.

Nokho, ukushisela igesi kunemikhawulo yakho. Izinga le-weld lithonywa kakhulu izinga lenduku ye-welding, futhi amalunga ahlanganisiwe athambekele ekuguquleni. Ukwengeza, ukusebenza kahle kokukhiqiza kuphansi kakhulu.

I-Laser Welding

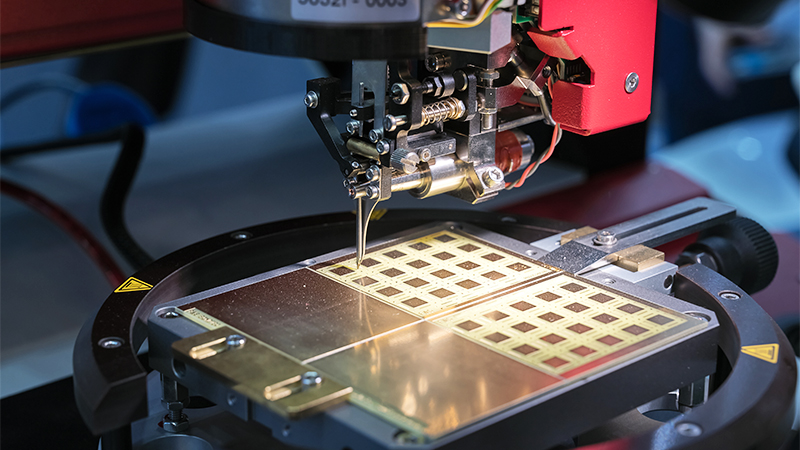

I-laser weldingisebenzisa i-laser beam njengomthombo wayo wokushisa. I-laser beam ishaya emaphethelweni ezinto zokusebenza zensimbi, ikhiqize ukushisa futhi yakhe idamu lokushisela. Lapho i-laser isuka, imiphetho yensimbi encibilikisiwe iphole futhi ihlangane ndawonye. Le ndlela ingasetshenziselwa ama-welds agqagqene, ama-butt weld, nama-welds avaliwe ezinhlelweni ezahlukahlukene zezimboni.

I-laser welding inesivinini esisheshayo sokushisela nokusebenza kahle okuphezulu, futhi ingasetshenziselwa ukushisela okungezona izinsimbi. Kuwubuchwepheshe bokushisela obusezingeni eliphezulu obusetshenziswa kabanzi ezimbonini ezinjengokukhiqiza izimoto, ugesi, nobucwebe. Nokho, ayikwazi ukungena ezintweni eziwugqinsi, ngakho-ke ifaneleka kakhulu ezintweni ezinodonga oluncane. Uma kuqhathaniswa nezinye izindlela zokushisela, imishini yokushisela i-laser ivame ukubiza kakhulu.

Cindezela i-Welding

Ngokungafani ne-fusion welding, i-pressure welding idinga ukufaka inani elithile lokucindezela ensimbi ngesikhathi senqubo yokushisela. Izinto zensimbi azincibiliki zibe uketshezi kodwa zihlala ziqinile. I-pressure welding ihlanganisa ukushisisa amalunga ensimbi ukuze kwandiswe ipulasitiki yawo, bese icindezela insimbi eyenziwe ngepulasitiki, okuholela ekuhlanganeni kwe-weld enamandla. Ngakho-ke, ingcindezi idlala indima ebalulekile kule nqubo.

Ngokuthuthuka komnotho wezimboni, kuye kwavela izinto eziningi ezintsha kanye nemikhiqizo, okuholela emisha eqhubekayo kubuchwepheshe be-welding welding. Izindlela eziyinhloko zokushisela ingcindezi okwamanje zihlanganisa ukumelana ne-welding, i-diffusion welding, i-friction welding, kanye ne-ultrasonic welding.

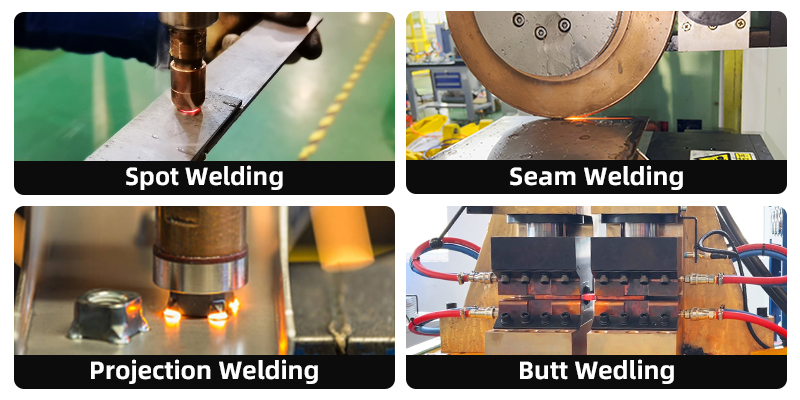

I-Resistance Welding

Ukumelana nokushiselaisebenzisa amandla kagesi ukushisa indawo yokuxhuma yensimbi ngenkathi isebenzisa ingcindezi ngama-electrode ukuze iqedele ukushisela. Ivame ukusetshenziselwa ukushisela insimbi engagqwali, ithusi, i-aluminium, ne-carbon steel. Ngenxa yekhwalithi yayo ephezulu nengaguquguquki yokushisela, i-resistance welding idlala indima ebalulekile ezimbonini zezimoto, ze-electronics, kanye ne-aerospace. Ngokuthuthuka kwezobuchwepheshe, i-resistance welding iye yanda ngokuhlanganisa i-automation, futhi ithuthukisa ukusebenza kahle kokukhiqiza.

I-Resistance welding ingahlukaniswa ngezindlela ezine:ukushisela indawo, i-projection welding,i-seam welding, futhiukushisela izinqe. Isibonelo, uma udinga ukushisela ingxenye yezimoto, njengokunamathisela inati epuleti lensimbi, ungasebenzisa i-projection welding. Kodwa-ke, imishini yokushisela i-resistance ngokuvamile inkulu futhi ayinyakazi kalula, ikhawulela ukusetshenziswa kwayo kuzilungiselelo ezithile. Isikhathi ngasinye lapho ushisela izinto ezihlukene zensimbi noma ubukhulu, imingcele idinga ukulungiswa, iyenze ifaneleke kakhulu ukushisela ivolumu ephezulu yezingxenye zensimbi.

I-Diffusion Welding

I-welding yokusabalalisa, eyaziwa nangokuthi i-diffusion bonding, ihlanganisa ukushisa nokusebenzisa ingcindezi endaweni yensimbi ngesikhathi sokushisela. Le nqubo ivumela ama-athomu nama-molecule wezinto zensimbi ukuthi ahlakazeke futhi ahlangane ngaphansi kwezinga lokushisa eliphezulu nokucindezela. I-Diffusion welding ingasetshenziselwa kokubili izinto ezifanayo nezingafani, ngokuvamile ezihlanganisa ithusi, i-aluminium, nezinto eziyinhlanganisela.

Le ndlela ingashisela kanyekanye amalunga amaningi emhlanganweni, njengokushisela izingqimba ezingama-20 zefoyili yethusi engu-0.1 mm. I-Diffusion welding idala amalunga aqinile amelana nokuguqulwa, ngokuvamile asusa isidingo sokuqhubeka nokucutshungulwa. Nokho, futhi inezihibe, okuhlanganisa ukusebenza kahle kokukhiqiza okuphansi kanye nezindleko eziphezulu zemishini.

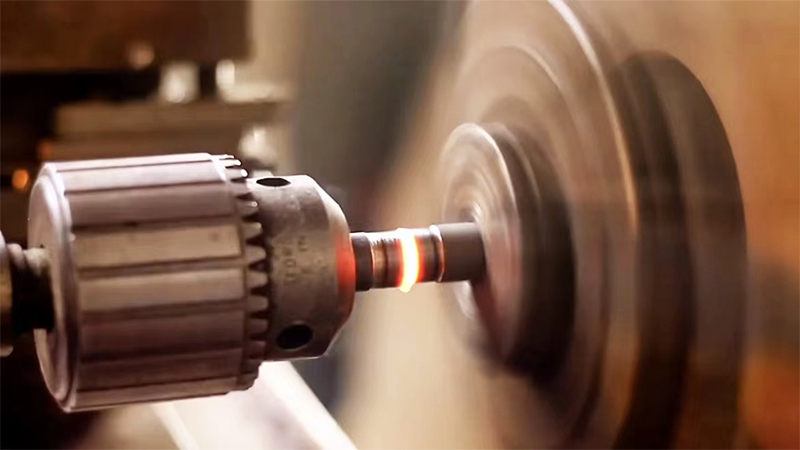

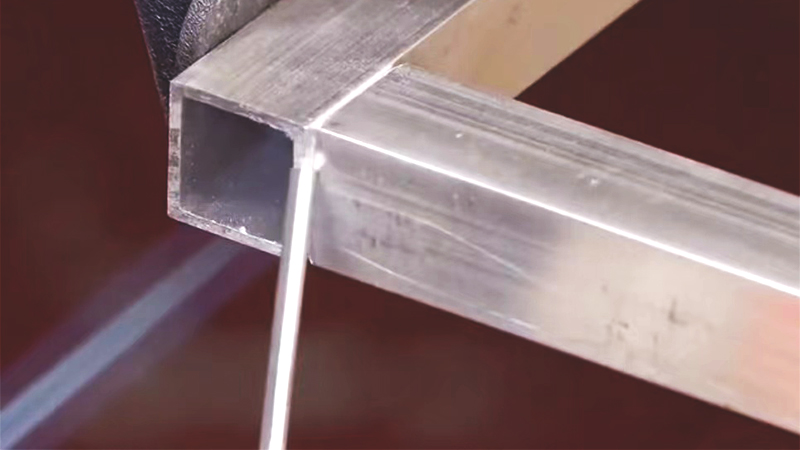

I-Friction Welding

I-friction weldingkuyinqubo yokushisela esebenzisa ukushisa okukhiqizwa kusukela ekunyakazeni okuhlobene phakathi kwezinto zokusebenza ngaphansi kwengcindezi. Kuyindlela ephumelelayo, yokonga amandla ekhiqiza amashiseyili ekhwalithi ephezulu. Uma kuqhathaniswa ne-flash butt welding, i-friction welding inendawo encane ethinteke ukushisa futhi ifaneleka kangcono ukuhlanganisa izinsimbi ezingafani.

I-Friction welding ihlukile futhi inikeza izinzuzo ezinjengokusetshenziswa kwamandla okuphansi kanye nobungane bemvelo, okuyenza idume ezimbonini ezifana nokukhiqiza imishini, i-aerospace, namandla. Kodwa-ke, ngokuvamile kufanelekile kuphela ukuxhuma izinduku zensimbi namapayipi obubanzi obufanayo. Uma ukuma kanye nendawo yokuhlanganisa yezinto zokusebenza sezilungisiwe, kuba inselele ukushisela.

I-Ultrasonic Welding

I-Ultrasonic welding isebenzisa ukudlidliza kwe-high-frequency okukhiqizwe amaza e-ultrasonic ukudala ukungqubuzana, ukuguqulwa, nokushisa ezindaweni ezithintana nensimbi. Ukucindezela kusetshenziswa izimpondo zomsindo ezingenhla neziphansi ukuze kuqedelwe inqubo yokushisela. Lena indlela eyingqayizivele yokushisela engafaki amandla kagesi adlula ezintweni zokusebenza noma emithonjeni yokushisa yangaphandle, futhi yabelana ngezici ezithile nokushisela okungqubuzanayo nokushisela okusabalalisa.

Ukushisa kwe-ultrasonicingasetshenziselwa izinto ezihlukahlukene, kufaka phakathi kokubili izinsimbi ezifanayo nezingafani njengethusi, i-aluminium, igolide, nesiliva. Kodwa-ke, isetshenziswa kakhulu ukushisela izinto ezingezona ezensimbi njenge-ABS, PP, ne-PC, lapho ikhiqiza khona imiphumela engcono kakhulu.

I-Brazing Welding

Ukubhuqakuyindlela yokushisela lapho insimbi yokugcwalisa enephuzu lokuncibilika ngezansi kwaleyo yezinto zokusebenza ishiswa futhi inyibilike ukuze kugcwaliswe izikhala phakathi kwezinto ezimbili zokusebenza zensimbi, kuphothula inqubo yokuhlanganisa insimbi. Ngokungafani ne-fusion welding kanye ne-pressure welding, le ndlela ayidingi ukuncibilikisa ama-workpieces noma ukufaka ingcindezi. I-Brazing isetshenziselwa ngokuyinhloko ukuhlanganisa ama-workpieces agqagqene, anosayizi wegebe ngokuvamile asukela ku-0.01 kuya ku-0.1 amamilimitha.

Namuhla, i-brazing isetshenziswa kakhulu kuzo zonke izimboni ezifana nemishini, izinto zikagesi, izinsimbi, nezibani. Izinga le-brazing lincike kakhulu ku-filler metal esetshenzisiwe. Ngakho-ke, lapho ubheka izinsimbi zokusebenza zensimbi, kubalulekile ukukhetha insimbi yokugcwalisa enezindawo ezinhle zokumanzisa ezingagcwalisa amalunga ngokuphumelelayo. I-Brazing ihlukaniswe yaba i-brazing ethambile kanye ne-brazing eqinile ngokusekelwe endaweni yokuncibilika yensimbi yokugcwalisa.

I-Soft Soldering

I-soldering ethambile isebenzisa izinsimbi zokugcwalisa ezinamaphoyinti ancibilikayo angaphansi kuka-450 degrees Celsius. Amalunga adalwe nge-solder ethambile anamandla aphansi kanye nokumelana nokushisa okungekuhle. Ivamise ukusetshenziselwa ukuxhunywa kukagesi emikhiqizweni ye-elekthronikhi enembayo kanye nokusoda ngezinsimbi zokunamathisela. Uma izidingo zamandla zingabalulekile futhi indawo yokuncibilika yensimbi yokugcwalisa iphakeme kunaleyo yensimbi ethengiswayo, i-soldering ethambile ingasetshenziswa.

Kanzima Kanjaloldering

I-Brazing enezinsimbi zokugcwalisa ezincibilika kakhulu, ezaziwa ngokuthi i-hard soldering, isebenzisa izinsimbi zokugcwalisa ezinamaphoyinti ancibilikayo angaphezu kuka-450 degrees Celsius. Amajoyinti adalwe nge-solder eqinile anamandla uma kuqhathaniswa nalawo asuka ku-solder ethambile. I-hard soldering ngokuvamile isebenzisa izinto ezifana nesiliva, i-aluminium, ithusi, ne-nickel. Ukukhethwa kwensimbi yokugcwalisa kuncike ezicini zezinto zokwenziwa komsebenzi kanye nezidingo zokusebenza zokuhlangana. I-Hard soldering ngokuvamile ifanelekela insimbi engagqwali, ama-alloys e-aluminium, ithusi, nezinye izinto ezinezidingo zamandla aphezulu. Isetshenziselwa amajoyinti asebenza ngaphansi kwamazinga okushisa aphezulu futhi ithola ukusetshenziswa okubanzi ku-aerospace, electronics, kanye nezimboni zikagesi.

Isiphetho

Kunezinhlobo ezahlukene zokushisela insimbi, futhi lezi ezishiwo ngenhla ziphakathi kwezindlela ezivame kakhulu. Njengoba ubuchwepheshe bokushisela buqhubeka nokuthuthuka, ziyanda izindlela zokushisela ziyavela. Uma ucabangela indlela yokushisela izingcezu zakho zokusebenza zensimbi, kubalulekile ukucabangela izici ezifana nempahla yomsebenzi, ukuma kwayo, indawo yokusebenza, nokunye. Ukukhetha indlela yokushisela efanele ngokusekelwe kulezi zici kubalulekile.

Isikhathi sokuthumela: Jun-19-2024