Spot weldingiwuhlobo lwe-resistance welding, njengenqubo esungulwe kahle esetshenziselwa ukuhlanganisa izinsimbi ezihlukahlukene, okwenza kube indlela ebalulekile ekusebenzeni kwensimbi yesimanje kwezimboni. Lesi sihloko sinikeza amathiphu okuzuza ukushisela okuqinile, okukhangayo, nezinzile:

Khetha OkulungileIbalaUkushiselaUmshini

Ukukhetha idivayisi efanele yokushisela indawo yokumelana kubalulekile. Gwema imishini emikhulu kakhulu enezici eziningi, njengoba lokhu kungamosha utshalomali. Ngokufanayo, ungakhethi umshini owanele, njengoba ungase ungavumeli ukwanda kwesikhathi esizayo noma ube nokumelana nokukhathala okuhle.

Inketho engcono kakhulu umshini okwazi ukushisela i-hard specication, ene-25% umthamo owengeziwe wokushisela wamanje kanye nengcindezi engaphezu kwamanje.sheet metal welding.

Ukusebenzisa umshini omkhulu kungabangela izinkinga eziningi njengomshini omncane kakhulu. Isibonelo, uma i-diameter yesilinda inkulu kakhulu, kufanele isebenze ngomfutho womoya ongaphansi kuka-0.2 MPa ukuze kuzuzwe ingcindezi yokushisela edingekayo. Lokhu kungaholela ekuphenduleni okubi okuvela kumshini wokufaka isicelo sokucindezela. Uma isilinda singenzi ngokushesha lapho insimbi ifinyelela esimweni sepulasitiki futhi idinga ukubunjwa ngokushesha, amandla e-weld nokuzinza kungahlupheka.

Izinkampani eziningi, ukuze kube lula ukuphatha imishini kanye nemingcele yokushisela iyunifomu, khetha imishini esekelwe kumamodeli ajwayelekile kunezidingo zenqubo yokushisela. Lokhu kungaholela ekusebenzisaneni kabi lapho kushiselwa izingxenye ezinkulu nezincane kakhulu. Leli iphutha elivamile lonjiniyela abangenalwazi. Indlela efanele ukufanisa usayizi wemishini nezinto zokusebenza ezishiselwe.

Thola ukuqeqeshwaIbalaUkushisela

Okokuqala, kubalulekile ukuqeqeshwa emigomeni nezindlela zokushisela. Ukuqonda imigomo ye-resistance spot welding kubalulekile ukulungisa kahle izinqubo zokushisela nokusebenzisa imishini ngendlela efanele.

I-Spot welding ingase ibonakale iqondile, njengoba kubonakala sengathi noma ubani angasebenza futhi alungiseumshini wokushisela indawo: beka izingxenye phakathi kwama-electrode, cindezela inkinobho yokuqala, futhi izingxenye zihlanganiswe ndawonye. Nokho, lokhu kuyakhohlisa. Kubalulekile ukuqonda ukubaluleka kwezinto zokushisela namapharamitha futhi ulungise ngayinye ibe ivelu elifanele.

Cabanga ngakho njengokupheka: izithako ezifanayo, kodwa izinongo ezihlukene, amazinga okushisa, nezikhathi zokupheka kungaveza ukunambitheka okuhluke kakhulu!

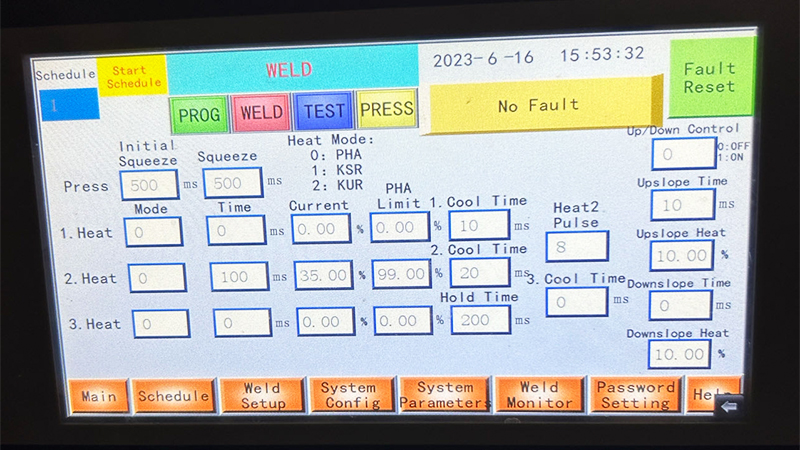

Izinto ezintathu ezibalulekile zokushisela indawo yi-welding current, isikhathi se-welding, kanye nengcindezi yokushisela. Imingcele eyengeziwe ihlanganisa isikhathi sangaphambi kwengcindezi, isikhathi se-welding interval, kanye nesikhathi sokubamba ngemva kokushisela.

Ngokuhlanganisa le mingcele, ungafinyelela ukucaciswa kokushisela okuqinile, okuphakathi, noma okuthambile, okuholela emiphumeleni ehlukene yokushisela, njenge:

Imininingwane eqinile:Ukuguqulwa kwengxenye encane, umthelela ophansi wokushisa, isivinini sokushisela esisheshayo, kodwa kudinga amandla aphezulu, aqinile, kanye nezisetshenziswa zokucindezela okuphezulu.

Imininingwane ethambile:Ukuwohloka kwengxenye ebalulekile, i-weld indentation ejulile, ukushintsha kombala, isivinini sokushisela esihamba kancane, kodwa amandla aphansi kanye nezidingo eziqinile zemishini.

Ukucaciswa okumaphakathi:Imithelela nezidingo zemishini ziwela phakathi kwalokhu okubili okweqisayo okungenhla.

Izincwadi zobungcweti ezifana ne-“Welding Handbook” zinikeza izincomo zepharamitha, futhi onjiniyela besevisi yezobuchwepheshe be-Agera banikeza ukuqeqeshwa okuphrofeshinali nesiqondiso kubasebenzisi.

Khetha OkulungileSpot WeldingAma-Electrodes

Ukuqhathanisa i-electrode material nengxenye kubalulekile ukuze uthole imiphumela emihle yokushisela kanye nokusebenza kahle kwamandla.

Okokushisela indawoi-aluminiumfuthiamashidi kathayela, sebenzisa ama-electrode ethusi ahlakazekile nge-alumina, amelana nokunamathela.

Ngobainsimbi engagqwalikanye namashidi ensimbi anekhabhoni ephansi, sebenzisa ama-electrode ethusi e-chromium zirconium, anikeza ukusebenza kahle kwezindleko eziphezulu.

Ngobaithusi, ama-electrode e-tungsten nama-molybdenum ayadingeka ukuze asize ngokushisela ngenxa yezindawo zawo zokushisa.

Ukuklama nokwakhiwa kobunjwa be-electrode nakho kubalulekile, njengoba kunquma usayizi nokubukeka kwe-weld nugget namandla ayo.

Setha amapharamitha we-Welding

Imingcele yokushisela ingasethwa ngokusekelwe kokuhlangenwe nakho noma idatha evela emithonjeni yomphakathi. Uma zingekho izithenjwa ezitholakalayo, ungathola kuphela amapharamitha wokushisela angcono kakhulu ngokusebenzisa ama-welds wesilingo amaningi anezilungiselelo ezihlukile. Lapho uhlola, landela lezi zimiso:

Qala Okuncane: Qala ngamavelu alandelanayo, amancane amapharamitha afana ne-welding current, isikhathi, nengcindezi, futhi kancane kancane uwanyuse. Le ndlela isiza ukugwema ukulimala kwemishini, ama-electrode, nezingxenye.

Lungisa Ipharamitha Eyodwa Ngesikhathi: Ukulungisa amapharamitha amaningi ngesikhathi esisodwa kungaholela ekwahluleleni okungalungile, ikakhulukazi kuma-opharetha angenalwazi. Uma ukulungisa okukodwa kungasebenzi, zama okunye ngenkathi ubheka ngokucophelela izinguquko kwikhwalithi yokushisela.

Vumela Amamajini Epharamitha: Qinisekisa ukuthi kunomkhawulo wamapharamitha ukuze amukele ukuhluka kwezingxenye.

Uma imingcele yokushisela engcono kakhulu isiqinisekisiwe, qinisa le datha futhi uyisebenzise njengesisekelo sokukhiqiza.

Gcina ama-Electrodes

Hlanza kabusha ama-electrode akhubazekile ukuze uwagcine kusayizi wawo owaklanywa ekuqaleni futhi uhlanze ukungcola nezinsalela zealloy yethusi endaweni yazo. Lokhu kunakekelwa kubalulekile ekushiseleleni okuzinzile.

Ama-Electrode asebenza ngaphansi kwengcindezi ephezulu kanye nezinga lokushisa angakhubaza, akhulise indawo yawo yokuxhumana nezingxenye futhi anciphise ukuminyana kwamanje kokushisela. Ukwengeza, i-surface coatings, uwoyela, nokugqwala okuvela ezingxenyeni kunganamathela kuma-electrode, okwandisa ukumelana nokuxhumana futhi kukhawule amandla welding. Lezi zinkinga zithinta ngqo ikhwalithi yokushisela.

Ukusebenzisa i-electrode dresser ekhethekile kungabuyisela ngokushesha ukwakheka kwe-electrode futhi kususe ukungcola okungaphezulu. Gwema ukusebenzisa ifayela lokuhlanza ngesandla, ngoba alikwazi ukuqinisekisa ukuma okufanelekile nokuqedwa kwendawo yama-electrode.

Sebenzisa i-Welding Inspection Equipment

Amajoyinti okushisela ama-spot ngokuvamile awahlolwa ngendlela engonakali. Izindlela zokuhlola ezijwayelekile zifaka ukuhlola okubonakalayo, ama-torque wrenches (amantongomane okushisela), imishini yokuhlola eqinile, nezihloli ze-metallographic.

Ukuhlola I-Tensile kanye Nokucindezela: Yenza lezi zivivinyo ngaphambi kokuqala usuku olugcwele lokukhiqiza ukuze uqinisekise ukwethembeka kwamapharamitha wokushisela ngesethi yedatha yokuhlola. Ekupheleni kweshifu ngayinye, hlola izingxenye ezishiselwe ngamapharamitha amanje futhi ukuze uqinisekise ukuvumelana. Ezingxenyeni ezibalulekile ezinezidingo zekhwalithi ephezulu, khulisa imvamisa yokuhlola okulimazayo.

Ukuqapha Inqubo: Ukusebenzisa amamonitha ekhwalithi yokushisela kungenye indlela, eseya ngokuya ihlonishwa futhi isetshenziswa kabanzi. Ngokuqapha amapharamitha we-welding ngesikhathi sangempela nokubeka imikhawulo ephezulu nephansi, noma yikuphi ukuphambuka kungabangela ama-alamu, kunciphise ukukhubazeka kokushisela. Le datha yokushisela ingagcinelwa ukulandeleka kwekhwalithi.

Ukunakekela kanye Nokuhlola Okuvamile

Ngemuva kokusetshenziswa isikhathi eside, imishini yokushisela i-Spot idinga ukuhlolwa njalo kulezi zindawo:

- I-Conductive Circuit:I-spatter yokushisela ingangena ezingxenyeni ezivaliwe kanye nezikhala, kubangele ukugoqa, ukunciphisa futhi kuphazamise amandla okushisela. Susa i-weld slag. Izinguquko ezivamile zama-electrode zingaguga futhi zenze i-oxidize uxhumano lwe-conductive, oludinga ukucutshungulwa kabusha. Qinisa amabhawudi ezintanjeni zethusi ezithambile kanye nezinsimbi zethusi eziqinile ukuze ugweme ukuxega ekusetshenzisweni isikhathi eside.

- I-Welding Cylinder Guide:Hlola ukunyakaza okushelelayo nezikhala. Ukushelela okungalungile kuthinta ukulandela kwe-weld; izikhala eziningi zithinta ukuma kwe-weld kanye nokuqondanisa kwengxenye.

- Umjikelezo Wamanzi:Qinisekisa ukugeleza kwamanzi okushelelayo. Hlanza amamitha okugeleza ukuze acace, hlola indlela yokuhamba ngayinye, futhi usule izithiyo noma shintsha amapayipi. Amanzi okupholisa anganele angashisa kakhulu ama-transformer nama-electrode, anciphise isikhathi sokuphila noma abangele ukutubeka. Hlola futhi ulungise ukuvuza.

- I-Welding Yamanje:Qinisekisa i-welding current ngomhloli wenkampani yangaphandle ukuze uqinisekise ukuthi ihlangabezana nezindinganiso. Ukusetshenziswa isikhathi eside kunganciphisa umthamo wamanje, ngakho-ke ukuhlolwa okuvamile nokuthuthukiswa noma ukulungiswa kungase kudingeke.

- Umjikelezo Womoya:Hlola futhi ulungise ukuvuza komoya, njengoba ukuvuza kubangela ingcindezi engazinzile nokulahlekelwa amandla.

- Inhlanzeko:Gcina impahla ihlanzekile. Izimpawu ezicacile kanye nemishini ehlanzekile kunciphisa amaphutha abantu.

Ihlobo

Lezi ezinye izincomo zabasebenzisi bemishini yokushisela ukumelana. Njengoba sineminyaka engaphezu kwengu-20 yokuhlangenwe nakho kwemboni yokushisela, sinikeza uhla oluphelele lwezinsizakalo, okuhlanganisa ukulungiswa kwesampula yokushisela, ukukhethwa komshini, imishini yokushisela ezenzakalelayo engajwayelekile, ukufakwa nokuthunywa, ukugcinwa, okokusebenza okusekelayo, nezingxenye. Zizwe ukhululekile ukuxhumana nathi!

Isikhathi sokuthumela: Jul-09-2024