Ngokuqhubeka okuqhubekayo kwesayensi nobuchwepheshe kanye nokuthuthuka okwandayo kokukhiqizwa kwezimboni, ubuchwepheshe be-resistance welding, njengendlela ebalulekile yokushisela, busetshenziswe kabanzi emikhakheni ehlukahlukene. Kodwa-ke, ubuchwepheshe bokushisela bendabuko bunezinkinga ezithile, njengokunemba kokulawula okuphansi, ukusetshenziswa kwamandla okuphezulu kanye nekhwalithi yokushisela engazinzile. Ukuze kuxazululwe lezi zinkinga, ubuchwepheshe bedijithali bungeniswa kubuchwepheshe be-resistance welding, okuthuthukisa kakhulu izinga le-automation kanye nekhwalithi ye-welding ye-resistance welding.

I-Digital resistance welding

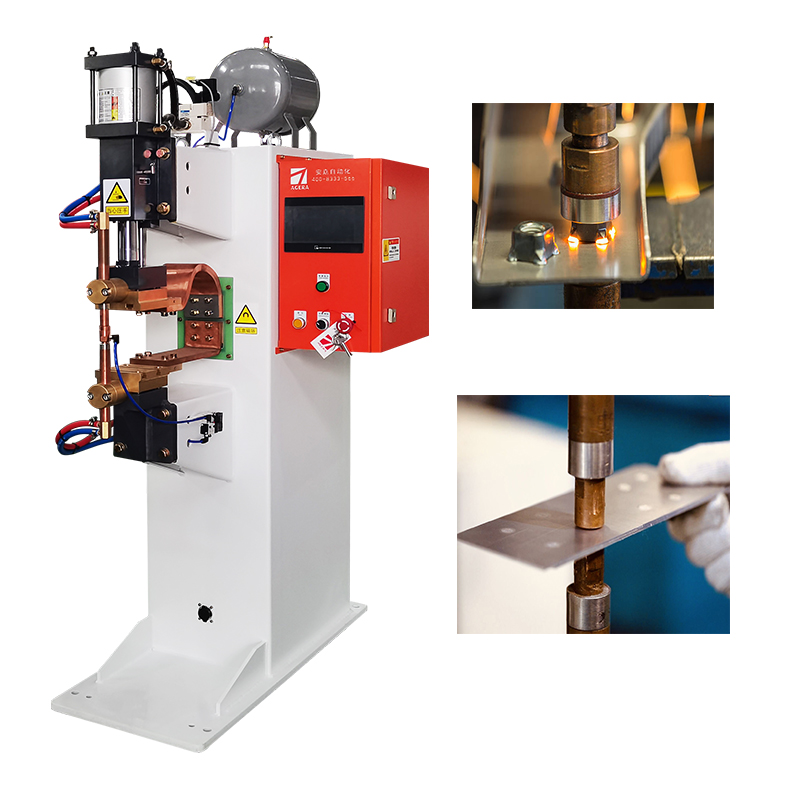

I-Digital resistance welding iwuhlobo lobuchwepheshe bokushisela obusebenzisa ubuchwepheshe bedijithali ukulawula ngokunembile kanye nokwandisa inqubo yokushisela ukumelana. Ingabona ukuqapha kwesikhathi sangempela kanye nokulungiswa okuzenzakalelayo kwenqubo yokushisela ngokucubungula kwedijithali kwemingcele yokushisela, idatha yokucubungula, isimo semishini nolunye ulwazi. I-Digital resistance welding inezici ezilandelayo:

1. Ukunemba okuphezulu kokulawula: i-digital resistance welding ingalawula ngokunembile i-welding yamanje, i-voltage, isikhathi kanye neminye imingcele ukuze kuqinisekiswe ukuzinza nokuvumelana kwekhwalithi ye-welding.

2. Izinga eliphakeme lokuzenzakalelayo: uhlelo lwe-digital resistance welding system lungakwazi ukubona ukulawulwa okuzenzakalelayo kwenqubo yokushisela, ukunciphisa ukungenelela okwenziwa ngesandla futhi kuthuthukise ukusebenza kahle kokukhiqiza.

3. Ukonga amandla kanye nokuvikelwa kwemvelo: Ngokuthuthukisa imingcele nezinqubo zokushisela, i-digital resistance welding inganciphisa ukusetshenziswa kwamandla futhi inciphise ukukhishwa kwezinto ezingcolile ezifana ne-waste gas kanye ne-slag.

4. Ukulandeleka okuqinile: uhlelo lwe-digital resistance welding lungarekhoda idatha kunqubo yokushisela, lunikeze ukwesekwa okuqinile kokulandelelwa kwekhwalithi yomkhiqizo.

Ukubaluleka kwedijithali kuukumelana nokushisela

1. Thuthukisa ikhwalithi yokushisela: ubuchwepheshe bedijithali bungalawula ngokunembile amapharamitha we-welding nezinqubo zokuqinisekisa ukuzinza nokuvumelana kwekhwalithi yokushisela nokuthuthukisa ikhwalithi yomkhiqizo.

2. Thuthukisa ukusebenza kahle kokukhiqiza: ubuchwepheshe bedijithali bungakwazi ukubona ukulawula okuzenzakalelayo kanye nokwenza kahle kweinqubo Welding, nciphisa ukungenelela okwenziwa ngesandla, futhi uthuthukise ukusebenza kahle kokukhiqiza.

3. Yehlisa izindleko zokukhiqiza: Ngokuthuthukisa imingcele ye-welding nezinqubo, ukushisela ukumelana nedijithali kunganciphisa ukusetshenziswa kwamandla nokusetshenziswa kwezinto ezibonakalayo, futhi kunciphise izindleko zokukhiqiza.

4. Ukuthuthukisa ukuncintisana kwamabhizinisi: ubuchwepheshe be-digital resistance welding bungathuthukisa izinga lobuchwepheshe kanye nezinga lokuphatha lamabhizinisi, futhi kuthuthukise ukuncintisana kwemakethe kanye nekhono lentuthuko esimeme lamabhizinisi.

Isicelo of digitization in ukumelana Welding

1. Ukulawula ipharamitha yokushisela

Enqubweni yokumelana ne-welding, ukulawulwa kwemingcele ye-welding kunomphumela obalulekile kwikhwalithi ye-welding. Ubuchwepheshe bedijithali bungaqapha futhi bulungise i-welding yamanje, i-voltage, isikhathi neminye imingcele ngesikhathi sangempela ukuze kuqinisekiswe ukuzinza nokuvumelana kwenqubo yokushisela.

2. Welding inqubo nokwenza kahle

Ubuchwepheshe bedijithali bungalungisa ngokuzenzakalelayo amapharamitha wenqubo yokushisela ngokuya ngezinto zokushisela, ukwakheka kwe-workpiece nokushuba nezinye izici ukuze kubonakale ukwenziwa kahle kwenqubo yokushisela. Ngokulingisa nokuhlaziywa kwedatha, isistimu yokushisela ukumelana nedijithali ingabikezela inkambu yokushisa, inkambu yokucindezeleka nezinye izinguquko enqubweni yokushisela, futhi inikeze isisekelo sesayensi sokuthuthukisa inqubo. Ngaphezu kwalokho, ubuchwepheshe bedijithali bungakwazi futhi ukufeza ukuqapha okukude kanye nokuxilongwa kwephutha kwenqubo yokushisela, ukuthuthukisa ukuthembeka nokuphila kwesevisi yemishini.

3. Ukuhlolwa kwekhwalithi yokushisela

Ubuchwepheshe bedijithali bungaqapha futhi buhlole ikhwalithi yokushisela ngesikhathi sangempela. Ngokuqoqa i-voltage, yamanje, izinga lokushisa kanye neminye imingcele enqubweni yokushisela, uhlelo lwe-digital resistance welding lungahlulela ukuthi ikhwalithi yokushisela iyahlangabezana yini nezidingo. Ngesikhathi esifanayo, ubuchwepheshe bedijithali bungakwazi futhi ukwenza ukuhlolwa okungabhubhisi kwamalunga ashiselwe ukuthola amaphutha kanye nezingozi ezifihliwe enqubweni yokushisela.

4. Ukuphatha okuhlakaniphile

Uhlelo lwe-digital resistance welding lungabona ukuphathwa okuhlakaniphile kwenqubo yokushisela. Ngokuhlanganiswa kwe-inthanethi Yezinto, idatha enkulu, i-cloud computing nobunye ubuchwepheshe, isistimu ye-digital resistance welding ingafinyelela ukuqapha kwesikhathi sangempela kwesimo semishini, ukuhlonzwa kwephutha kanye nokugcinwa kwesixwayiso kusenesikhathi. Ngaphezu kwalokho, ubuchwepheshe bedijithali bungakwazi futhi ukubona isibonisi esibonakalayo kanye nokuhlaziywa kwedatha yenqubo yokushisela, okuhlinzeka ngokusekela okuqinile kwezinqumo zokukhiqiza.

Njengomhlinzeki wesixazululo soxhumano lwensimbi ohamba phambili emhlabeni, i-Agera iphinde ihlole njalo indlela yokuthuthukisa yokushisela ukumelana nedijithali, kwathi ngo-2022, yathuthukisa futhi yakhiqiza uhlelo lokuqapha ikhwalithi yokushisela ngesikhathi sangempela i-HRC650, okuwumshini onembayo. Ingasetshenziselwa ukutholwa kwesikhathi sangempela ngesivinini esiphezulu samanje, i-voltage yesibili, ukumelana nokuhlangana, ukususwa kwe-electrode, idatha yengcindezi ye-electrode namajika athinta ikhwalithi ye-weld, futhi ububanzi bomkhawulo wedatha ngayinye ingasethwa ngayinye. Uma idatha idlula inani elishiwo, ungakhipha i-alamu bese usetha ijika lemvilophu.

Ukusetshenziswa kwedijithali kubuchwepheshe be-resistance welding sekuyinkambo engenakugwemeka ekuthuthukisweni kwemboni. Ngokuthuthuka okuqhubekayo kanye nokuthuthukiswa kobuchwepheshe bedijithali, ubuchwepheshe be-resistance welding buzofeza inqubo yokushisela esebenza kahle, enembile futhi ehlakaniphile. Ngokuzayo, i-Agera izoqhubeka nokuhlola umgwaqo wokushisela ukumelana nedijithali futhi inikeze ukwesekwa okuqinile koshintsho nokuthuthukiswa kokukhiqizwa kwezimboni.

Isikhathi sokuthumela: Jun-13-2024