Ukushisela izinqeisetshenziswa kakhulu ekucutshungulweni kwensimbi yesimanje, ngobuchwepheshe bokushisela izinqe, insimbi efanayo noma insimbi engafani njengethusi ne-aluminium ingabambana ngokuqinile ndawonye. Ngokuthuthuka kwemboni, ubuchwepheshe be-butt welding busetshenziswa kakhulu ku-elekthronikhi nekagesi, izimoto zamandla amasha nezinye izimboni. Isihloko esilandelayo sizophendula ulwazi lwe-butt welding yakho ngokuningiliziwe.

OkuyisisekeloCkanyeButtWelding

Okubizwa ngokuthi i-butt welding ukubeka iziphetho ezimbili zokusebenza ngokuhlobene nomunye nomunye, faka ingcindezi ngesikhathi esifanayo, sebenzisa i-welding current ukushisa, bese wenza i-welding joint ngaphansi kwesenzo sokucindezela, i-automation ephumelelayo futhi kulula ukuyifinyelela. indlela yenqubo ye-welding.

The Izinhlobo of ButtWelding

I-butt welding ihlukaniswe kakhuluukumelana butt weldingfuthiflash butt welding

I-Resistance butt welding

I-Resistance butt welding iwuhlobo lwesigaba esiqinile sokushisela esimweni sepulasitiki sokushisa okuphezulu, futhi ukuxhumana okuhlanganyelwe kungase kube ukubuyiswa kabusha kanye nokusabalalisa okuhlangene empeleni, kodwa konke ukuxhumana kwesigaba esiqinile.

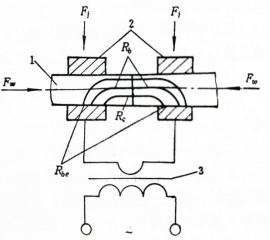

Umgomo we-resistance butt welding kanye nokwakheka okuhlangene kukhonjisiwe kuMfanekiso 1.

Umfanekiso 1. Umdwebo wesakhiwo se-Resistance butt welding

1- Ukushisela

2 - Electrode

3- I-Solder resistance transformer

4-FF- clamping force

Fw - amandla okwenza

I-Rb - ukumelana nokushisela

Ukumelana ne-RC-Contact

I-Rbe- Ukumelana nokuxhumana phakathi kwe-weldment kanye ne-workpiece

I-Flash Butt Welding

Ingqikithi yokuxhuma ye-flash butt welding joint iyafana neyokuhlangana kwe-butt welding, okubuye kube uxhumano lwesigaba esiqinile, kodwa inqubo yokwakheka inezici zayo. Ekupheleni kwe-flash, kuye kwakhiwa ungqimba lwensimbi oluwuketshezi ebusweni bokuphela. Ngesikhathi sokubumba okuphezulu, insimbi yobuso bokugcina iqala ukuhlanganiswa ngaphansi kwesigaba se-liquid. Khona-ke ungqimba lwesigaba se-liquid luzokhama luphume ebusweni bokuphela obuhlangene ngaphansi kwesenzo sokucindezela okuphezulu kwe-forging.Ngemva kweflash butt welding umshiniizingxenye ezishiselwe, ilunga linamandla kakhulu, njengeshubhu lensimbi ngokusebenzisa i-flash welding, bese kuthiumshini wokugoba i-tubeukugoba ekuhlanganyeleni, ilunga ngeke liphuke.

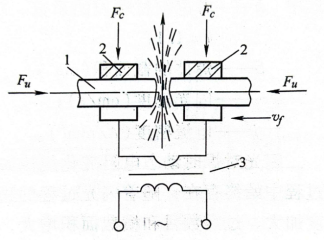

Umgomo we-flash butt welding kanye nokwakheka okuhlangene kukhonjisiwe kuMfanekiso 2:

Umfanekiso 2. I-flash butt welding schematic diagram

1- Ukushisela

2 - Electrode

3- I-Solder resistance transformer

4- Fc- clamping force Fu- forging force Vf flash speed

Izinzuzo zeButtWelding

a) Imishini yokushisela izinqe ilula, imingcele embalwa yokushisela, kulula ukuyiqonda, kulula ukuyifinyelela ukulawula okuzenzakalelayo;

b) Ukuncishiswa okuncane kwezingxenye zokushisela izinqe zokumelana, izinto zokonga, ama-burrs amancane, okusiza ekwenzeni inqubo yakamuva ibe lula;

c) i-flash butt welding inokushisa okuphezulu okuphezulu, ingashisela izingxenye ezisendaweni enkulu, futhi isetshenziselwe ukushisela amapayipi egesi anendawo enqamulayo engu-100000mm2;

d) i-flash butt welding ngoba i-lintel ikhona isikhathi esifushane, ama-millisecond ambalwa kuphela, isikhundla sawo sishintsha ngokungahleliwe, futhi isikhathi esiphelele sokushisa kulo lonke ubuso bokuphela kwe-weldment sifana kakhulu, ngakho-ke i-flash welding eqhubekayo ayikwazi ukushisela ingxenye ehlangene, kodwa futhi i-weld welds enezigaba ezinwetshiwe (njengamashidi amancane, njll.);

e) Ekupheleni kwe-flash, ungqimba oluncane lwensimbi oluwuketshezi luzokwakhiwa ebusweni be-weldment, ukuze ukungcola kwe-oxide ebusweni kube lula ukukukhipha ngensimbi ewuketshezi engxenyeni ephezulu ye-interface, ngakho-ke ukuthi i-flash butt welding joint esezingeni eliphezulu, futhi izinhlobo zokushisela zingaba ngaphezulu, futhi izinhlobonhlobo zezinto ezihlukahlukene zingashiswa.

f) Asikho isigcwalisi esidingekayo enqubweni yokushisela, futhi izinga lokusebenzisa impahla liphezulu;

Isicelo seButtWelding

Ukukhiqiza Izimoto

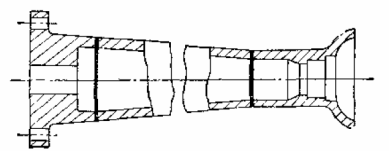

Umfanekiso 3. I-automobile cardan shaft shell flash butt welding

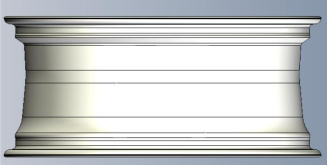

Umfanekiso 4. Imoto, isondo lesithuthuthu i-flash butt welding

Imboni ye-Aerospace

Umfanekiso 5. Ukushisela izinqe zendiza yendiza

Imboni ye-Petrochemical

Umfanekiso 6. Amapayipi ensimbi e-butt welding

Inkambu yobunjiniyela bokwakha

Umfanekiso 7. End plate flange butt welding

Imboni yokwakha imikhumbi

Umfanekiso 8. Welding chain butt welding

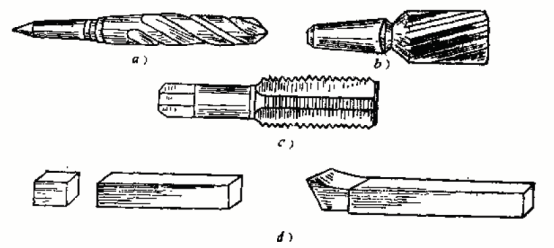

amathuluzi wehadiwe

Umfanekiso 9. Ukushisela izinqe zethuluzi

SukucaciswaPama-aramu kuButtWeldingPi-rocess

Lapho kukhethwa imingcele efanele yokucaciswa kwe-butt welding, amalunga ekhwalithi ephezulu anezindawo ezicishe zifane nezinto eziyisisekelo zingatholakala.

a) Imingcele yokucaciswa eyinhloko ye-resistance butt welding yilezi:

ubude bokwelula, ukuminyana kwe-welding yamanje (nomawelding current), isikhathi sokushisela, ingcindezi ye-welding kanye nengcindezi ephezulu yokubumba.

b) Imingcele eyinhloko ye-flash butt welding yilezi:

Isiteji se-Flash: ukulungisa ubude bokwelula, ukugcinwa kwe-flash, isivinini se-flash, ukuminyana kwamanje kwe-flash;

Isiteji sokufoja esiphezulu: isibonelelo sokukhanga esiphezulu, ijubane eliphezulu lokufoja, umfutho wokufoja ophezulu, amandla okubamba;

Isiteji sokushisa: ukushisa kwangaphambi kokushisa, isikhathi sokushisa.

Umsebenzi we-welding ubude ukuqinisekisa imvume edingekayo (welding ingxenye shortening) futhi ulungise insimu lokushisa lapho kushisa ukubaluleka kanye umsebenzi ingakhethwa ngokuvumelana Welding ingxenye ingxenye kanye impahla impahla, umkhuba ubonisa ukuthi ubude ukwelula akufanele kube ngaphansi. kunengxenye yobubanzi bengxenye yokushisela, okungukuthi, l = 0.6 ~ 1.0d(d ububanzi bepulangwe noma ubude obuhlangothini besikwele) kufanelekile. Ngesikhathi esifanayo, lapho ushisela izinto ezihlukene, ukuze uthole ukusabalalisa okulinganiselayo okushisa (ngezinye izikhathi kucatshangelwa ukuqina kokushisela okungezona insimbi), ama-weldments amabili kufanele asebenzise ubude obuhlukene bokwelula.

I-welding current ivame ukuvezwa ukuminyana kwamanje, futhi ukuminyana kwamanje kanye nesikhathi se-welding yimingcele emibili eyinhloko enquma ukushisa kwe-welding, futhi ingalungiswa ngokufanele komunye nomunye. Ekusebenzeni, kunconywa ukugcina ubudlelwano obuthile phakathi kobuningi bamanje kanye nesikhathi esincane se-welding, futhi kusetshenziswe ukucaciswa okunzima njengoba isigaba sesiphambano sincipha. Ukuminyana kwamanje kwe-flash butt welding eqhubekayo, izinto zensimbi ezine-conductivity enhle kagesi kanye ne-thermal, nezingxenye ezishiselwe ezinesigaba esinwetshiwe kufanele zibe phezulu. Ukuze ushise ngaphambili i-flash butt welding kanye nokushisela kwesigaba esikhulu, ukuminyana kwamanje kufanele kube phansi.

Kokubili ingcindezi yokushisela kanye nengcindezi ephezulu yokubumba kunomthelela ekuncibilikeni kokushisa kwendawo yokuxhumana kanye nokuguqulwa kwepulasitiki kwezindawo eziphambene neziseduze. Isivinini sokufoja esiphezulu kanye nomfutho we-forging force ephezulu singamataniswa, futhi isivinini sokufoja esiphezulu singancishiswa ngokufanele uma isivinini sokufoja esiphezulu sikhulu ngokwanele.

IDukuthuthukiswaPithemba leButtWelding

Ngocwaningo olujulile lobudlelwano phakathi kwekhwalithi yokushisela ukumelana nemingcele yenqubo yokushisela kanye nobuchwepheshe bokubona ku-inthanethi, izinga lokushisela elizinzile lingatholakala. Ngaphezu kwalokho, izinto zokushisela ziye zandiswa ngokwengeziwe, futhi uhla lwesicelo sokumelana ne-welding luya ngokuya lubanzi. Ngokuqhubeka okuqhubekayo kweukumelana ne-welding technology, ukumelana ne-welding kuzoba nesikhundla esibaluleke kakhulu ekukhiqizeni kwezimboni esikhathini esizayo. Ikakhulukazi emkhakheni wokushisela we-cross-section enkulu nezinsimbi ezingafani, i-flash butt welding inethuba elihle lokuthuthuka.

Isifinyezo

Ngokuthuthukiswa kwemboni entsha yamandla, izicelo zokushisela ezengeziwe zethusi ne-aluminium uxhumano, ubuchwepheshe be-welding bokumelana buhambisana nezidingo zemakethe, kuhlangene nenqubo yokushisela entsha yokumelana nobuchwepheshe bokulawula okuguquguqukayo, ukumelana nokushisela esikhathini esizayo thola umphumela omkhulu.

Isikhathi sokuthumela: Aug-30-2024