Uma umusha ku-resistance welding noma ufuna ukuqonda okucacile ngakho, kufanele nakanjani ufunde lesi sihloko ngokucophelela. Lesi sihloko sizokuthatha ujule emhlabeni we-resistance welding. Kungakhathaliseki ukuthi uyaqala noma ufuna ukwandisa ulwazi lwakho, lesi sihloko sizokunikeza imininingwane ebalulekile.

Iyini i-Resistance Welding?

I-Resistance welding iyindlela yokuhlanganisa insimbi enesivinini esikhulu, eyongayo. Le ndlela yokushisela ilungele amalunga ethangeni, amalunga ezinqe, noma amalunga angadingi ukucinana komoya, anogqinsi olungaphansi kuka-6mm ezakhiweni zamashidi amancane. Vele, ingakwazi futhi ukushisela izinsimbi ezishubile nezikhudlwana, kodwa ukusebenza kwayo sekukonke kungase kungabi kuhle njengezinye izindlela zokushisela.

Incazelo kanye Nezisekelo

Ukumelana nokushiselakuyindlela lapho ama-workpieces okufanele ahlanganiswe abekwe phakathi kwama-electrode amabili. Ngokudlula okwamanje kuma-workpieces kanye namaphoyinti okuxhumana, ukushisa kokumelana kwenzeka, okukhiqiza ukushisa lapho kuhlangana khona ama-workpieces. Lokhu kushisisa kwendawo kubangela ukuthi indawo inyibilike noma ikwazi ukuphenduleka, kuyilapho ingcindezi evela kuma-electrode amabili ibopha insimbi ndawonye.

Uma i-current igeleza ku-conductor, ikhiqiza ukushisa ngenxa yokumelana. Ukuphakama kokumelana lapho i-current ihlala njalo, ukushisa okwengeziwe kukhiqizwa. Esikhathini lapho izinsimbi zithintana khona, ukumelana kukhulu kakhulu kunangaphakathi kwensimbi ngokwayo. Ngakho-ke, lapho umsinga omkhulu udlula lapho kuhlangana khona insimbi ne-electrode, insimbi ishisa ngokushesha ngenxa yokushisa okukhulu. Kuleli qophelo, insimbi iba yi-ductile kakhulu, futhi ngokucindezela okusetshenzisiwe, izingcezu ezimbili zensimbi zibopha ndawonye ngokuphephile.

Isimiso Sokusebenza Sokumelana Ne-Welding

Umgomo we-resistance spot welding kanye nokwakheka kwamalunga kuboniswe kuMfanekiso 1-1. Insimbi A kanye nensimbi B kubekwa phakathi kwama-electrode amabili, futhi ingcindezi isetshenziswa kuma-electrode. I-current enamandla idluliswa phakathi kwama-electrode amabili yi-transformer ye-welder yokumelana. Izindawo zokuthintana zezingxenye zokusebenza zakha indawo yokuxhumana ngokomzimba, ekhula kancane kancane njengoba yamanje ilishisa. I-deformation yepulasitiki nokushisa kuvula ngokuqhubekayo ama-athomu endaweni yokuxhumana, okuholela ekwakhekeni kwengqikithi encibilikisiwe. Umnyombo oncibilikisiwe ukhula ngendlela yamakristalu ekholomu, ephusha izakhi zokuhlushwa eziphakeme ze-alloy ziye komunye nomunye. Lapho ama-electrode we-welder esuka endaweni yensimbi, futhi insimbi iphola, izinto zokusebenza zihlanganiswa ndawonye, zakhe isibopho esiqinile sensimbi. Indawo ehlangene iyanyamalala, ishiye ngemuva kwe-weld nugget.

1-1

Izici Ezithinta Ukumelana Ne-Welding

Ukumelana nokushiselakuyindlela yokushisela esebenzisa amandla kagesi ukuze akhiqize ukushisa ukuze ahlanganise izingxenye zensimbi. Njengoba kushiwo ngaphambili, isimiso sokumelana nokushisela ngokuyinhloko sisuka emthethweni kaJoule wokushisa, lapho ukukhiqizwa kokushisa kwe-welding kunqunywa ngokuyinhloko ngamapharamitha afana namanje, ukumelana, nesikhathi sokushisela. Ingavezwa ngefomula elandelayo:

Q = I²Rt

Incazelo yepharamitha yokushisela ngayinye:

Q - Ukushisa (J)

I - Welding current (A)

R — Ukumelana (Ω)

t - Isikhathi sokushisela (s)

I-Welding Yamanje

I-current inomthelela omkhulu ekushiseni okukhiqizwa ngesikhathi sokushisela, njengoba kuboniswe kufomula. Inani lesikwele lamanje lithinta ukushisa, okusho ukuthi ukuphakama kwamanje, ukushisa kuzokhula ngokushesha. Ngakho-ke, lapho ulungisa amapharamitha we-welding ngaphambi kokushisela, kubalulekile ukusetha wamanje ofanele. Uma i-welding current incane kakhulu, i-weld ngeke incibilike, futhi akukho core we-fusion ozokwakheka. Uma i-current inkulu kakhulu, i-fusion core izokhula ngokushesha, ibangele ukusabalalisa ngokweqile ngesikhathi sokushisela futhi kulimaze ama-electrode.

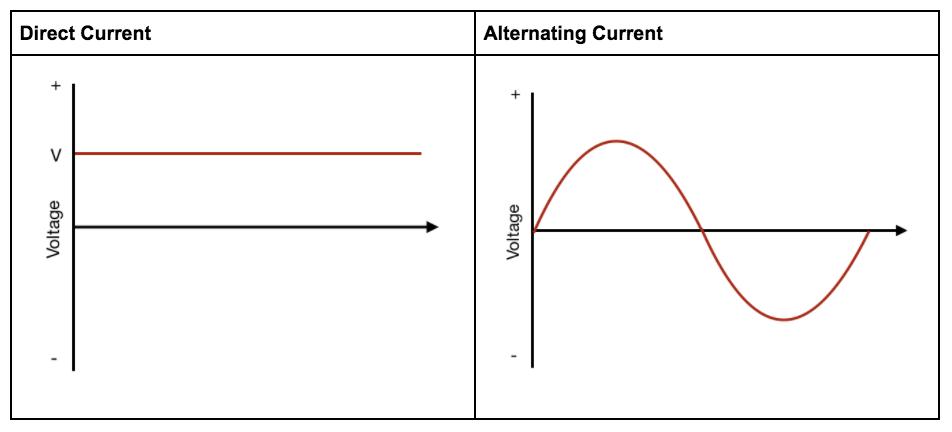

I-Welding current ihlukaniswe ngokuyinhloko ibe i-alternating current (AC) kanye neyamanje eqondile (DC), njengoba kukhonjisiwe kumdwebo ongezansi. Iimishini yokushisela amabalasisebenzisa futhi ihlukaniswe yaba imishini yokushisela indawo yamanje kanye nemishini yokushisela yamanje eshintshayo. Imishini yamanje yokushisela indawo isebenzisa ugesi wezigaba ezintathu, iqinisekisa ukusatshalaliswa kwamandla okulinganayo, futhi ingafinyelela amaza okushisela angaphezu kuka-1000 Hz, okuholela ekunembeni okuphezulu kokushisela. Futhi banenzuzo yokufunwa kwamandla aphansi kusuka kugridi yamandla, okwenza lezi zishiseli zonga amandla zidume kakhulu phakathi kwabakhiqizi bemboni yokukhiqiza. Imishini yokushisela indawo yamanje eshintshanayo inokukhiphayo kwesigaba esisodwa okungu-50Hz, umthamo oqhubekayo wokulayisha oqhubekayo, kanye nezidingo eziphezulu zegridi yamandla. Ukwengeza, banamandla okushisela aphansi, adinga izikhathi ezinde zokushisela.

Xhumana Nokumelana

Kusuka kufomula, kulula ukubona ukuthi ukumelana kuhambisana ngokuqondile nokushisa okukhiqizwayo. Ukuphakama kokumelana, kukhulu ukushisa okukhiqizwa ngesikhathi sokushisela. Ukumelana kusatshalaliswa kuzo zonke izingxenye ezahlukahlukene ze-electrode kanye ne-workpiece. Ngesikhathi sokushisela, ukumelana okuphezulu kwenzeka endaweni yokuxhumana ye-workpiece, okuholela ekukhiqizeni ukushisa okuphezulu kakhulu. Okulandelayo ukumelana endaweni yokuxhumana phakathi kwe-workpiece ne-electrode. Kodwa-ke, njengoba i-electrode ipholile ngamanzi futhi ipholisa ngokushesha, izinga lokushisa liyehla ngokushesha. Ngakolunye uhlangothi, ukumelana nokuxhumana phakathi kwama-workpieces, nakuba kuyanyamalala, kunokushisa okungahambi kahle, okuholela emazingeni okushisa aphezulu. Ngakho-ke, indawo encane kuphela phakathi kwama-workpieces ingafinyelela izinga lokushisa elidingekayo ukuze kwakhiwe umgogodla we-fusion futhi weld ndawonye.

Ukwengeza, izinga lokushisa nokucindezela kwe-electrode kuthinta ukumelana. Njengoba izinga lokushisa likhuphuka, amandla okukhiqiza insimbi ayancipha, okwandisa indawo yokuxhumana phakathi kwama-workpieces naphakathi kwendawo yokusebenza kanye ne-electrode, okuholela ekwehleni ukumelana. Ukwenyuka kwengcindezi ye-electrode kwenza indawo yokusebenza ibe bushelelezi, ikhulise indawo yokuxhumana futhi inciphise ukumelana. Ngenxa yalokho, kunento ethile lapho, ngesikhathi sokushiselwa kwezinto ezivamile, ukumelana kukhuphuka ngokushesha ngemva kokukhanyisa, futhi lapho amandla ecishiwe futhi amafomu e-fusion core, ukumelana kuqala ukuncipha.

Isikhathi sokushisela

Uma isikhathi sokushisela sikhula, ukushisa okukhiqizwayo kuyanda. Kule fomula, okwamanje nesikhathi kungaphelelisana. Uma ufuna i-weld eqinile, ungasetha i-current ephezulu isikhathi esifushane ukuze ukhiqize ukushisa ngokushesha futhi wenze i-fusion core ukuze uqedele ukushisela. Kungenjalo, ungasetha i-current ephansi isikhathi eside, kodwa kunomkhawulo kule ndlela. Uma isikhathi sisethwe side kakhulu, kungaholela ekusakazeni ngokweqile futhi kungase kubangele ukuthi i-electrode inamathele. Noma ngabe okwamanje noma yisikhathi, kunemikhawulo. Lapho ubeka imingcele, udinga ukucabangela izinto ezibonakalayo nobukhulu be-workpiece, kanye namandla omshini wokushisela.

Izinto ezibonakalayo

Impahla ye-workpiece ithinta kakhulu ukumelana kwayo, okudlala indima ebalulekile ekukhiqizeni ukushisa kwe-welding. Uma ushisela insimbi engagqwali, enokumelana okuphezulu kanye nokungaguquki kahle kwe-thermal, kulula ukukhiqiza ukushisa kodwa kube nzima ukukuchitha, ngakho-ke kudingeka imisinga emincane. Uma ushisela ama-alloys e-aluminium ane-resistivity ephansi kanye ne-thermal conductivity enhle, kuba nzima ukukhiqiza ukushisa kodwa kulula ukukuhlakaza, ngakho-ke kudingeka imisinga emikhulu. Izinsimbi ezifana nesiliva nethusi zinokusebenza okuphezulu kwe-thermal kanye ne-resistivity ephansi, ngakho-ke ngisho namagagasi aphezulu, awakhiqizi ukushisa okuningi kodwa angakuhambisa kude. Ngakho-ke, lezi zinsimbi azifaneleki ukushisela ukumelana kodwa zingasetshenziswa njengezinto ze-electrode.

I-Electrode Design kanye neJiyomethri

Ukuma kanye nempahla ye-electrode nakho kuthinta ukukhiqizwa kokushisa. Indawo yokuxhumana phakathi kwe-electrode kanye ne-workpiece ithinta ukuminyana kwamanje. Ukusetshenziswa njalo kwama-electrode kungaholela ekugqokeni nasekuguqukeni, kwandise indawo yokuxhumana nokunciphisa amandla okushisela. Ngakho-ke, sidinga ukulungisa nokushintsha amathiphu we-electrode ngokushesha. I-conductivity eshisayo kanye nokumelana kwe-electrode kuthinta ukudluliswa kokushisa. Ngakho-ke, kufanele sikhethe izinto ezine-conductivity ezinhle ezishisayo kanye nokumelana okuphansi.

Ukulungiswa kwendawo

Ukuma kanye nempahla yama-electrode nakho kuthinta ukukhiqizwa kokushisa. Indawo yokuxhumana phakathi kwe-electrode kanye ne-workpiece ithinta ukuminyana kwamanje. Uma ama-electrode ethu esetshenziswa njalo futhi eguga, kwandisa indawo yokuxhumana, okuholela ekunciphiseni amandla okushisela. Ngakho-ke, sidinga ukulungisa nokushintsha amathiphu e-electrode ngokushesha. I-conductivity eshisayo kanye ne-resistiveivity yama-electrode kuthinta ukudluliswa kokushisa. Ngakho-ke, kufanele sikhethe izinto ezine-conductivity enhle ezishisayo kanye nokumelana okuphansi.

Izinhlobo ze-Resiukuma Welding

Ngenxa yokucaciswa kwemikhiqizo ehlukene kanye nezidingo zokushisela, izinqubo ezihlukene zokushisela zisetshenziselwa ukuqedela umsebenzi. I-Resistance welding ingahlukaniswa ibe yi-spot welding, i-projection welding, i-seam welding, kanye ne-butt welding ngokusekelwe kunqubo yokushisela.

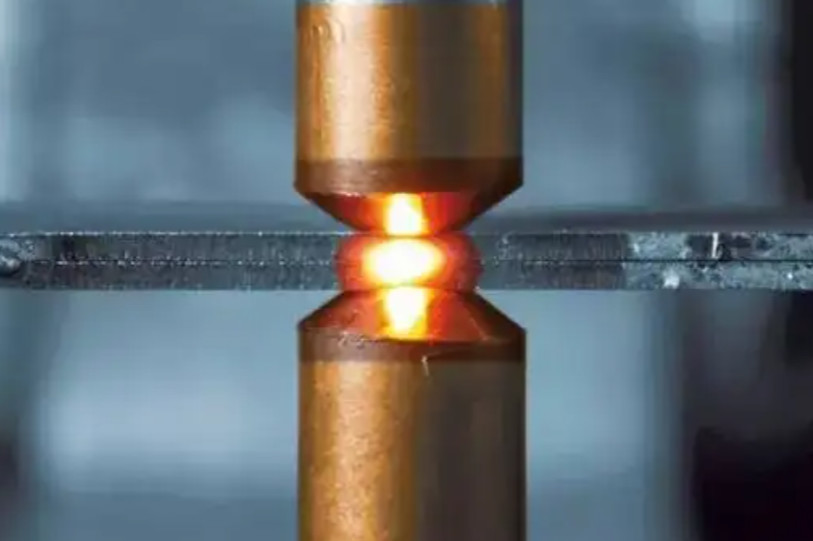

Spot Welding

Spot weldingkuyindlela yokushisela lapho insimbi icindezelwa ndawonye ngama-electrode angaphezulu naphansi futhi ashiselwe ngokudlula okwamanje kuwo. Kuyindlela evamile yokushisela ukumelana, kulula ukuyisebenzisa, futhi kudinga amazinga aphansi wamakhono kubasebenzi. Ngenxa yenqubo yokushisela eyingqayizivele, i-spot welding iyisinqumo esiyinhloko sokushisela izingxenye zensimbi kubunjiniyela be-aerospace futhi isetshenziswa kakhulu ekushiseleni umzimba wezimoto nezinye izakhi. Ngokuvamile isetshenziselwa ukushisela amashidi azacile ensimbi yensimbi ephansi, i-aluminium, insimbi engagqwali, insimbi eyakhiwe ngothayela, namanye amapuleti amancane, ngokuvamile acishe abe amamilimitha angu-3 ubukhulu.

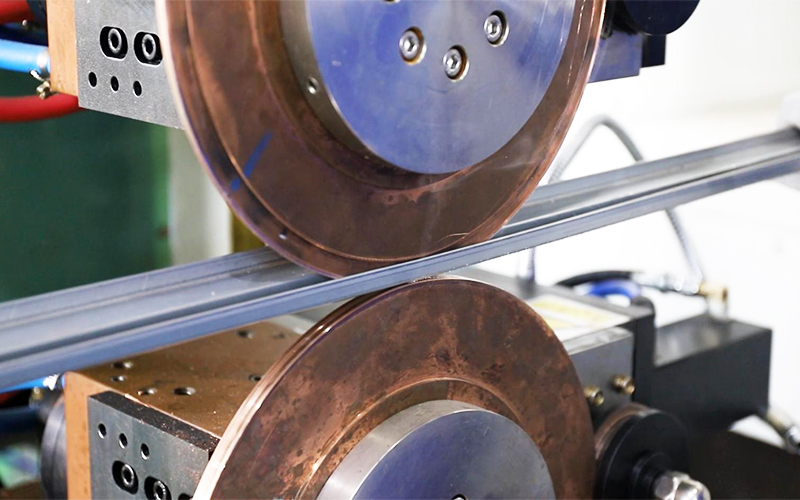

I-Seam Welding

Ukushisela umthungongokuvamile kuhlanganisa ukuhlanganisa imiphetho yezingxenye ezimbili zensimbi. Ama-workpieces amabili ensimbi abekwe phakathi kwama-roller electrode amabili. Ngenkathi i-electrode eyodwa iginqika futhi ifaka ingcindezi, ukuphuma okuqhubekayo noma okuphakathi kwenzeka. Ukushisa okukhiqizwa endaweni yokuginqika ye-electrode kuncibilikisa izingcezu zokusebenza futhi kuzihlanganise, kwenze umthungo wokushisela oqhubekayo. Le ndlela isetshenziswa kabanzi ukushisela izingxenye zensimbi ezidinga amalunga avaliwe. Njengoba indawo yokushisela iyinde uma kuqhathaniswa, ukuvimbela ukungahambi kahle, ngokuvamile sisebenzisa i-spot welding ukuze simise ngaphambi kwe-seam welding.

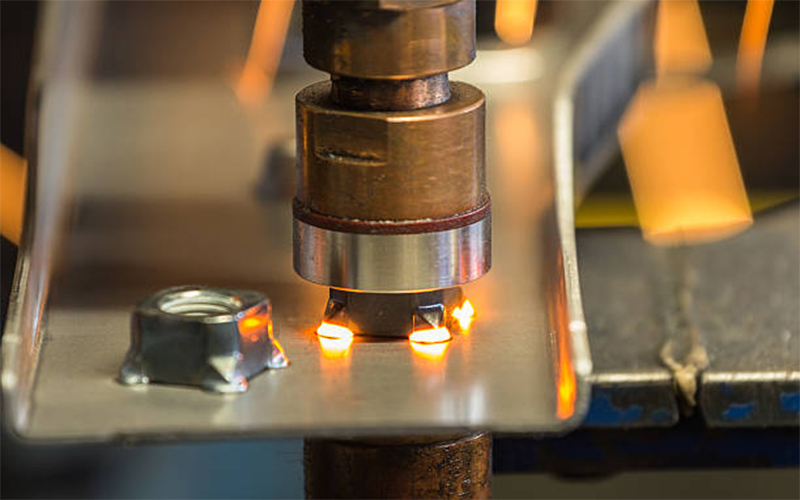

I-Projection Welding

I-Projection Weldingkuwukuhlukahluka kokushisela indawo, lapho ukwakheka kwephoyinti lokushisela kufana nokushisela amabala, kodwa i-projection welding ngokuvamile isetshenziselwa izingcezu zokusebenza ezinamaphoyinti aphakanyisiwe. Ukuba khona kwalawa maphuzu aphakanyisiwe kunciphisa indawo lapho i-current idlula khona, okwandisa ukuminyana kwamanje endaweni ye-welding. Lokhu kushisa okugxilile kusiza ukuxhumana kwesihlanganisi. Le ndlela yokushisela yaziwa ngokuthi i-projection welding. I-Projection welding ingakha i-fusion cores eyodwa noma ngaphezulu endaweni eyodwa ngesikhathi esisodwa. Ngesikhathi sokushisela, okwamanje okudingekayo ekushiseleleni i-projection endaweni efanayo ye-weld incane kunaleyo yokushisela indawo. Nokho, ngaphambi kokuba ukuqagela ngakunye kuchotshozwe, okwamanje kudinga ukuncibilikisa ukuqagela; ngaphandle kwalokho, kungase kube nenani elibalulekile le-spatter. I-Projection welding ingasetshenziselwa ukushisela amantongomane, amabhawodi, noma amapuleti anamaphuzu aphakanyisiwe futhi isetshenziswa kabanzi ekwenzeni izinto zikagesi nezezimoto.

Ukushisela izinqe

Ukushisela izinqekuhilela ukuqondanisa ubuso bokugcina bezinto zokusebenza ezimbili zensimbi, ukuzibeka phakathi kwama-electrode, ukubopha ngokuvikelekile izinto zokusebenza ezimbili, nokusebenzisa amandla aphezulu ukukhiqiza ukushisa, ukuncibilikisa indawo yokuthintana yezinto zokusebenza nokuzihlanganisa ndawonye. I-Butt welding iphinde ihlukaniswe ibe i-flash butt welding kanye ne-resistance butt welding.

I-Flash butt welding iyinqubo yokushisela esheshayo esebenzisa ihigh current ukuze incibilikise ngokushesha izinto zokusebenza, ifake ingcindezi yokwenza uxhumano lwesigaba esiqinile. Ivamise ukusetshenziselwa ukushisela izindawo ezinkulu eziphambanayo zezinduku zensimbi, amashidi, namapayipi, nezindawo eziphezulu ezifinyelela ku-20,000mm² nangaphezulu. Ngesikhathi sokukhishwa kwe-welding, izinhlansi zikhiqizwa endaweni yokuxhumana, yingakho igama elithi flash butt welding. Ingakwazi ukushisela i-carbon steel ephezulu, insimbi engagqwali, ama-alloys e-aluminium, futhi ingashisela izinsimbi ezingafani njengethusi ne-aluminium.

I-Resistance butt welding isebenzisa ukushisa kokumelana ukuze ilethe amajoyinti e-workpiece esimweni sepulasitiki emazingeni okushisa aphezulu, kuphothula inqubo yokushisela ngamandla okubumba. Ilungele amajoyinti okushisela anezindawo eziphambanayo phakathi kuka-250mm², evame ukusetshenziselwa ukushisela izintambo zensimbi eziphambanayo, izinti, namapheshana.

Ukubaluleka Kwezokukhiqiza

- I-Resistance welding ayidingi ukufakwa kwensimbi phakathi nenqubo yokushisela, okuholela ekusebenzeni kahle kwe-welding kanye nokungcola okuncane.

- Ngenxa yokungaguquguquki nokuzinza kwayo, i-resistance welding kulula ukuzenzela, ihlanganiswe ngaphandle komthungo ne-automation ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza nokusindisa abasebenzi.

- Uma kuqhathaniswa nezinye izindlela zokushisela, i-resistance welding iyabiza. Okokuqala, izindleko zemishini ye-resistance welding ziphansi, futhi okwesibili, kukhona imfucumfucu encane ngesikhathi senqubo yokushisela. Lokhu kunciphisa kakhulu izindleko zokukhiqiza kubakhiqizi embonini yokukhiqiza.

- I-Resistance welding isetshenziswa kabanzi kuzo zonke izimboni ezihlukahlukene futhi ibaluleke kakhulu emikhakheni efana ne-aerospace, ukukhiqizwa kwezimoto, nokunye.

- I-Resistance welding ifanele ukushisela izinhlobo ezihlukahlukene zezinsimbi embonini yokukhiqiza, okuhlanganisa insimbi engagqwali, i-carbon steel, i-aluminium, ithusi, nokunye, okuyenza ibe nezinto ezihlukahlukene ekusetshenzisweni kwayo.

Izinhlelo zokusebenza

I-Resistance welding isetshenziswa kabanzi, ikakhulukazi ezimbonini ezifana nezingxenye zezimoto, i-aerospace, i-electronics, kanye nezimboni ezisindayo. Njengoba isidingo sezingxenye zensimbi ezishiselwe ezimbonini ezihlukahlukene siqhubeka sikhula, amazinga aphezulu obuchwepheshe bokushisela asethiwe, aqhuba inqubekelaphambili nokuthuthukiswa kokumelana nokushisela.

Izicelo Zemboni Yezimoto

Ekwenziweni kwezimoto, lapho ukuphepha nokuzinza kubaluleke kakhulu, i-resistance welding iyindlela evame ukusetshenziswa. Ngokuvamile isetshenziselwa ukuhlanganisa izingxenye zensimbi ezihlukahlukene emizimbeni yezimoto, njengophahla, izicabha, amashidi ensimbi, namantongomane ensimbi. I-Resistance welding inikeza ukusebenza kahle okuphezulu, ikhwalithi yokushisela ezinzile, futhi i-othomathikhi kalula, okwenza kube inqubo ebalulekile embonini yokukhiqiza izimoto.

Izicelo Zemboni Yezindiza

I-Resistance welding ivame ukusetshenziselwa ukuxhuma izingxenye zensimbi ezindizeni namarokhethi, njengokuhlanganisa amaphiko endiza namafuselage, kanye nezingxenye zensimbi ezihlukahlukene. Lezi zingxenye kufanele zibe namandla aphezulu kanye nokuqina, nezidingo eziqinile zekhwalithi yamalunga, okuyilapho ukushisela ukumelana kuphumelela khona. I-resistance welding idlala indima ebalulekile embonini ye-aerospace, futhi intuthuko kulo mkhakha ibuye yenziwe lula umkhakha we-aerospace.

Izicelo Zemboni Yezogesi

I-Resistor welding ivame ukusetshenziselwa izingxenye ze-elekthronikhi nezingxenye ezithile zensimbi kumishini kagesi. Inikeza ukunemba okuphezulu kwe-welding futhi ifanele ukuxhuma izingxenye ezincane ezifana nama-electron chips nezintambo. Enkathini yanamuhla ethuthuka ngokushesha yezinto zikagesi, i-resistor welding isheshisa ukuhlangana kwezingxenye ze-elekthronikhi, ithuthukise imbonini.

Izicelo Zemboni Enzima

I-Resistance welding ivame ukusetshenziselwa ukushisela izingxenye ezinkulu zensimbi kumabhuloho nezakhiwo, njengama-flange angaphansi kwebhuloho kanye nokuqinisa insimbi. Iphinde isetshenziswe ekwenzeni imishini emikhulu yokuxhuma izingxenye zensimbi. Ngobuchwepheshe bayo bokushisela obusebenza kahle futhi obuzinzile, ukushiswa kwe-resistance kuye kwaba enye yezindlela ezibalulekile zokucubungula embonini esindayo. Iqinisekisa ukuphepha kwemishini esindayo nezakhiwo.

Izisetshenziswa kanye Nezingxenye

Imishini yokushisela

Imishini yokushisela ukumelanaihlukaniswe yaba izigaba ezine eziyinhloko: imishini yokushisela indawo, imishini yokushisela i-projection, imishini yokushisela i-seam, nemishini yokushisela izinqe, ngokusekelwe ezinkambisweni ezahlukene. Khetha imishini yokushisela efanele ngokuya ngezimpawu zezinto zokwakha kanye nokuma.

Ama-Electrodes

Ii-electrodekuyingxenye ebalulekile yokuqinisekisa ikhwalithi yokushisela. Izinto eziyinhloko zama-electrode wokushisela yilezi: ithusi le-chromium zirconium, i-aluminium oxide yethusi, ithusi le-beryllium cobalt, i-tungsten, i-molybdenum, i-graphite, njll. Kuye ngokuthi i-workpieces ehlukene eshiselwe, ama-electrode ahlukaniswa abe ama-electrode ayisicaba, ama-electrode ayindilinga, ama-electrode amantongomane, ibholidi. ama-electrode, njll. Ngokuvamile, ukulungiswa kwe-electrode kuhilela ukufaka ama-tapered, nge ama-taper ratios kakhulukazi ku-1:10 naku-1:5.

Amasistimu Okupholisa

Ngesikhathi sokusebenza, imishini yokushisela ukumelana idinga amanzi ajikelezayo ukuze kuphole izingxenye ezifana nama-electrode nama-transformer. Ngakho-ke, sifaka uhlelo lokupholisa lwemishini yokushisela ukumelana. Ukushisa kwamanzi okupholisa kufanele kube ngaphansi kuka-30°C. Uma izinga lokushisa liphezulu kakhulu, kungase kubangele ukuvalwa kokuvikela komshini wokushisela. Kungcono ukusebenzisa amanzi okupholisa angenakungcola ukuze ajikeleze ukuvikela amabala amanzi nokuvinjwa kwamapayipi.

Indlela Yokukhetha Inqubo Yokushisela Elungile?

Ukukhethwa kwendlela ye-welding kuncike ezintweni eziningi.

Ubugqinsi nobujamo bomsebenzi: Okuhlukileizindlela zokushiselazilungele izingcezu zokusebenza ezinobukhulu obuhlukahlukene kanye nokwakheka. Isibonelo, i-resistance welding ngokuvamile ifaneleka kuphela ukushisela amashidi ensimbi amancane, kuyilapho izinto zokusebenza ezinomumo ngendlela engavamile neziwugqinsi zivame ukushiselwa kusetshenziswa i-arc welding.

Izidingo Zekhwalithi Yokushisela: Ikhwalithi yokushisela oyifunayo ibuye inqume ukukhetha kwendlela yokushisela. Kuma-workpieces adinga ukubekwa uphawu okuphezulu namandla ahlangene, izindlela zokushisela ezihlangabezana nalezi zidingo kufanele zikhethwe.

Ukusebenza Kahle Kokukhiqiza Nezindleko: Uma kudingeka umthamo omkhulu wokukhiqiza wonyaka, ukukhetha indlela yokushisela esebenza kahle kakhulu kuyadingeka. Ukucatshangelwa kwezindleko kufanele kucatshangelwe.

Izici Zendawo Ezungezile: Ezinye izindlela zokushisela zikhiqiza imfucumfucu kanye nesisi esikhipha umoya, okubangela ukungcoliswa kwemvelo. Ngakho-ke, ukucatshangelwa kwemvelo kufanele kucatshangelwe lapho kukhethwa indlela yokushisela.

I-FAQ:

Yimiphi imikhawulo ye-resistance welding?

I-Resistance welding ayifanele ukushisela izingxenye ezinkulu zensimbi.

Uqinisekisa kanjani ukuphepha ku-resistance welding?

Lapho usebenzisa ukushisela ukumelana, gqoka isigqoko sokuzivikela kanye nezibuko zokuphepha.

Ngingaqeqeshwa kanjani nge-resistance welding?

Ungakwazi ukuqeqeshwa at aukumelana nomkhiqizi we-welding.

Yiziphi izinkinga zekhwalithi eziyinhloko zamajoyini we-welding welding?

I-cold solder joint, amandla anganele, i-welding deformation, i-oxidation.

Izindlela zokuhlola amajoyinti we-resistance welding

Ukuhlolwa okulimazayo, ukuhlolwa kwe-microscopic, ukuhlolwa okubonakalayo, ukuhlolwa kwe-metallographic, ukuhlolwa kwe-ultrasonic.

Isikhathi sokuthumela: Apr-02-2024