Ukushisela i-Seam kuyinqubo eyinkimbinkimbi yokushisela.Le ndatshana ihlola ubunkimbinkimbi bokushisela i-seam, kusukela ezimisweni zokusebenza zokusebenza kuya ekusetshenzisweni kwayo, izinzuzo, nezinselele. Kungakhathaliseki ukuthi umusha ekushiseleni noma ufuna ukujulisa ukuqonda kwakho le nqubo ebalulekile yezimboni, lo mhlahlandlela uzokunikeza imininingwane ebalulekile yokuthi i-seam welding isebenza kanjani nokuthi isetshenziswa kuphi ngokuvamile.

Isingeniso se-Seam Welding

I-seam welding wuhlobo olukhethekile lweukumelana Welding inqubolapho izingcezu ezimbili noma ngaphezulu zensimbi zihlanganiswa ndawonye eduze komthungo oqhubekayo noma uchungechunge lokushisela kwamabala agqagqene. Isetshenziswa kakhulu ezimbonini ezidinga amajoyinti angangeni moya noma angangeni manzi, njengemikhakha yezimoto, i-aerospace, kanye neyokukhiqiza. Ngokungafani nokushisela indawo okujwayelekile, okudala amaphuzu okushisela ngamanye, ukushisela komthungo kukhiqiza i-weld eqhubekayo, eqinile ngokusebenzisa ama-electrode ajikelezayo ahamba eduze kwelunga, ehlanganisa izinto ndawonye.

Isebenza kanjani i-Seam Welding

I-Seam welding isebenza ngesimiso esifanayo esiyisisekelo njenge-resistance welding:ukumelana nogesi kusetshenziselwa ukukhiqiza ukushisa, okuncibilikisa izinto ezishiselwe ndawonye. Kodwa-ke, i-seam welding iyazihlukanisa ngokuthi i-weld isetshenziswa kanjani ngokuqhubekayo phakathi nobude be-workpiece. Ngezansi ukuhlukaniswa kwezingxenye ezibalulekile nokuthi inqubo isebenza kanjani.

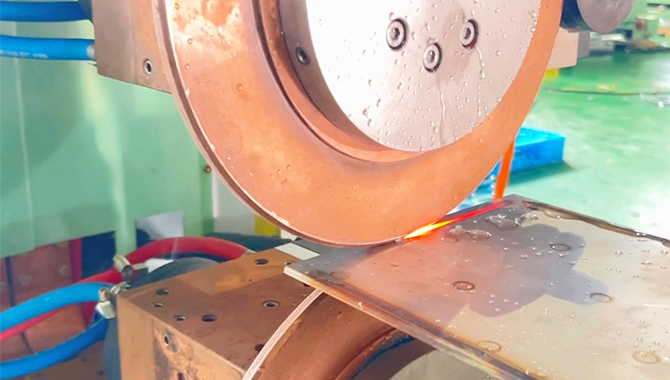

Ama-Electrode Ajikelezayo:Inhliziyo yenqubo ye-welding ye-seam ukusetshenziswa kwama-electrode amabili ajikelezayo, ajikelezayo, ngokuvamile enziwe ngethusi noma ezinye izinto zokuhambisa. Lawa ma-electrode acindezela izingcezu zensimbi, anikeze kokubili amandla kagesi kanye namandla emishini adingekayo ukuze kudaleke i-weld. Njengoba ama-electrode ejikeleza, ahamba ngobude bejoyinti, esebenzisa ukucindezela kanye namanje ngokuqhubekayo.

Uhlelo lokusebenza lwamanje:Umsinga kagesi udlula kuma-electrode, okwenza ukumelana nendawo lapho izingcezu ezimbili zensimbi zithinta khona. Ukumelana kukhiqiza ukushisa, okwenza izinsimbi zincibilike futhi zihlangane ndawonye. Ku-seam welding, lokhu kwamanje kusetshenziswa ngendlela eshayayo noma eqhubekayo, kuye ngohlobo oluthile lokushisela (okuxoxwe ngakho ngezansi).

Ingcindezi Nokupholisa:Njengoba i-current igeleza, ama-electrode ajikelezayo afaka ingcindezi engashintshi endaweni yokusebenza, eqinisekisa ukuthi into encibilikisiwe iyaqina ibe ukushisela okuqinile, okuqhubekayo. Ama-electrode asebenza njengendlela yokupholisa, esiza ukulawula izinga lokushisa nokuvimbela ukushisa ngokweqile, okungalimaza i-weld noma izinto ezizungezile.

Ukunyakaza Okuqhubekayo:Isenzo esijikelezayo sama-electrode yikho okwenza i-seam welding ihluke kwezinye izindlela zokushisela ukumelana. Ama-electrode ahamba emgqeni ohlangene ngesivinini esilawulwayo, eqinisekisa ukuthi ukushisa kusetshenziswa ngokulinganayo kubo bonke ubude bomthungo. I-weld ewumphumela iqinile, ayiguquguquki, futhi imvamisa iqinile emoyeni noma iqinile.

Izinhlobo ze-Seam Welding

I-Seam welding ingahlukaniswa ngezinhlobo ezimbili eziyinhloko ngokusekelwe endleleni yamanje esetshenziswa ngayo:

I-Seam Welding eqhubekayo

Kule ndlela, ugesi oqhubekayo usetshenziswa ngenkathi ama-electrode ehamba eduze kwelunga. Lokhu kubangela ukushisela okuqhubekayo okufana nobuhlalu. Ukushisela i-seam okuqhubekayo kuvame ukusetshenziswa lapho kudingekile isivalo esingangeni moya noma esingangeni manzi, njengasemathangeni noma emapayipini kaphethiloli.

I-Intermittent Seam Welding

Eyaziwa nangokuthi i-roll spot welding, le ndlela isebenzisa amandla kagesi kuma-pulses ngenkathi ama-electrode ehamba. Umphumela uba uchungechunge lokushisela kwamabala agqagqene akha umthungo. Lolu hlobo lokushisela i-seam luvame ukusetshenziswa lapho ubuqotho besakhiwo bubaluleke kakhulu kunokungangeni komoya, njengasezinhlelweni ezithile zezimoto.

Izinto Ezifanele Ukushisela I-Seam

Umshini wokushisela umthungoisebenza kahle kakhulu ezinsimbi ezihambisa ugesi kahle futhi ezinendawo encibilikayo ephansi. Izinto ezijwayelekile zifaka:

Insimbi:Zombili izinsimbi ezinekhabhoni ephansi nezingagqwali zivame ukushiselwa ezinsizeni zezimoto nezimboni.

I-Aluminium:Nakuba kuyinselele kakhulu ngenxa yokwenziwa kwayo okuphezulu, i-aluminium ivamise ukushiselwa emkhathini nasekukhiqizeni.

Ama-Copper Alloys:Ithusi'I-conductivity enhle kakhulu iyenza ilungele ukusetshenziswa ezingxenyeni ezidinga ukusebenza kahle okushisayo nogesi, njengama-radiator kanye nezivalo zikagesi.

Izicelo ze-Seam Welding

I-Seam welding isetshenziswa kakhulu ezimbonini ezidinga amandla aphezulu, ama-airtight, noma amajoyinti aqinile. Ngezansi ezinye zezinhlelo zokusebenza ezivame kakhulu:

Imboni Yezimoto:Ukushisela i-Seam kuvame ukusetshenziswa ekukhiqizeni izingxenye zezimoto ezifana namathangi kaphethiloli, ama-muffler, namasondo amasondo. I-weld eqhubekayo iqinisekisa ukuthi lezi zingxenye azingeni moya futhi zihlala isikhathi eside, zikwazi ukumelana nezindawo ezinokhahlo kanye nezingcindezi eziphezulu.

I-Aerospace:Imboni ye-aerospace ngokuvamile idinga izingxenye ezingasindi kodwa eziqinile, futhi ukushisela ngomthungo kusetshenziswa ukuhlanganisa amashidi amancane e-aluminium nensimbi. Kulo mkhakha, isidingo samajoyinti athembekile, angangeni moya, futhi angangeni manzi sibalulekile ezinhlelweni zikaphethiloli nezingxenye zesakhiwo.

Ukwenziwa Kwamathangi Neziqukathi:Ukushisela i-Seam kusetshenziswa kakhulu ukwenza amathangi kaphethiloli, amathangi amanzi, neziqukathi zamakhemikhali okudingeka zivalwe ngokuphelele ukuze kuvinjelwe ukuvuza. Ulayini we-weld oqhubekayo uqinisekisa ubuqotho bethangi, okwenza lifaneleke ukubamba uketshezi noma amagesi ngaphansi kwengcindezi.

Amapayipi Ensimbi namashubhu:Ukushisela i-Seam kusetshenziselwa ukwenza amapayipi ensimbi namashubhu ezimboni ezihlukahlukene, okuhlanganisa uwoyela negesi, amapayipi amanzi, kanye nezokwakha. Indlela iqinisekisa umthungo oqhubekayo, ongavuzi ongamelana nokucindezela kwangaphakathi.

Iphakheji Yokudla Nesiphuzo:Embonini yokupakisha, i-seam welding isetshenziswa ukwenza amathini ensimbi, iziqukathi nezivalo. Ukunemba kanye nesivinini sokushisela i-seam kukwenza kube ukukhetha okuhle ekukhiqizeni ngezinga elikhulu, ukuqinisekisa ukuthi imikhiqizo ivalwe ngokuvikelekile futhi ihlala inyumba.

Izingxenye zikagesi:I-Seam welding iphinde isetshenziselwe ukwenza izinto ezifana nama-radiator, izinto zokufudumeza, nezivalo zikagesi. Umthungo oqhubekayo uqinisekisa ukuqhubeka kukagesi nobuqotho besakhiwo.

Izinzuzo ze-Seam Welding

Ukushisela i-Seam kunikeza izinzuzo ezimbalwa ngaphezu kwamanye amasu okushisela, okwenza kube ukukhetha okudumile ezimbonini ezidinga amalunga aqinile, asezingeni eliphezulu. Nazi ezinye zezinzuzo ezibalulekile:

Isivinini nokusebenza kahle: I-Seam welding iphumelela kakhulu, ikakhulukazi kuzilungiselelo eziqhubekayo zokukhiqiza. Inqubo ezenzakalelayo ivumela ukushisela okusheshayo kubo bonke ubude bomthungo, kunciphisa isikhathi sokukhiqiza.

Ukushisela Okuqinile, Okungaguquguquki: Imvelo eqhubekayo yokushisela i-seam iqinisekisa ukuthi i-weld ifana ngokufanayo kulo lonke ilunga, okuholela ekuxhumekeni okunamandla, okuthembeke kakhulu. Lokhu kuvumelana kunciphisa ubungozi bokukhubazeka njengokuqhekeka noma izindawo ezibuthakathaka.

Ama-Seal angangeni futhi angangeni manzi: I-Seam welding ilungele ukusetshenziswa lapho ijoyinti kufanele livalwe ngokuphelele, njengakumathangi, amapayipi, neziqukathi. I-weld eqhubekayo iqinisekisa ukuthi azikho izikhala okungadlula kuzo umoya noma uketshezi.

Ukuhlanekezela Okuncane: Ngenxa yokuthi ukushisa kwe-welding kwenziwa endaweni futhi ama-electrode ahlinzeka ngokupholisa okuqhubekayo, i-seam welding ikhiqiza ukuhlanekezela okuncane ezintweni ezizungezile. Lokhu kubaluleke kakhulu uma usebenza ngezinsimbi ezizacile ezijwayele ukungqubuzana.

I-Automation-Friendly: Izinqubo zokushisela i-Seam zihambisana kakhulu ne-automation, zizenza zilungele izindawo zokukhiqiza ezinkulu. Imishini yokushisela i-seam ezenzakalelayo ingaveza imiphumela engaguquki ngokungenelela kwabantu okuncane, ukunciphisa izindleko zabasebenzi kanye nokukhiqiza okwandayo.

Izinselelo kanye nemikhawulo ye-Seam Welding

Nakuba i-seam welding inezinzuzo eziningi, ibuye iveze izinselelo nemikhawulo ethile:

Izindleko Eziphezulu Zezisetshenziswa:Izinto eziyisipesheli ezidingekayo zokushisela i-seam, ikakhulukazi ukushisela i-seam ngokuqhubekayo, zingabiza. Lokhu kuyenza ingafinyeleleki kalula kumaworkshop amancane noma izinkampani ezinesabelomali esilinganiselwe.

Imikhawulo yezinto:I-Seam welding isebenza kahle kakhulu ezinsimbi ezisetshenziswayo njengensimbi ne-aluminium. Izinto ezingasebenzi kahle noma ezingezwani nokushisa, njengamapulasitiki athile noma izitsha zobumba, azikwazi ukushiselwa kusetshenziswa le ndlela.

Ukulinganiselwa kokuqina:Ukushisela i-Seam kuphumelela kakhulu ezintweni ezizacile, ngokuvamile ezingaphansi kuka-3mm ngogqinsi. Ngezinto eziwugqinsi, ezinye izindlela zokushisela, njenge-MIG noma i-TIG yokushisela, zingase zifaneleke kakhulu.

I-Electrode Wear:Ukujikeleza njalo nokucindezela kwama-electrode kungaholela ekuguge ngokuhamba kwesikhathi, ikakhulukazi uma izinto zokushisela njengensimbi engabangela ukuwohloka kwe-electrode. Ukugcinwa njalo nokushintshwa kwama-electrode kuyadingeka ukuze kuqinisekiswe ukusebenza okungaguquki.

Isiphetho

Ukushisela i-Seam kuyinqubo ebalulekile ekukhiqizeni kwesimanje, enikeza indlela ethembekile, ephumelelayo yokwakha ama-welds aqinile, aqhubekayo. Izicelo zayo zinkulu, ezihlanganisa izimboni ezinjengezezimoto, i-aerospace, kanye nokupakisha, lapho isidingo samajoyinti angangeni moya noma angangeni amanzi sibalulekile. Ngekhono layo lokukhiqiza ama-welds angaguquguquki, ahlala isikhathi eside ngokushesha, i-seam welding iyindlela ethandwayo yezindawo zokukhiqiza eziphezulu.

Kodwa-ke, kubalulekile ukucabangela ukulinganiselwa kwe-seam welding, ikakhulukazi mayelana nezindleko zemishini kanye nokuhambisana kwezinto ezibonakalayo. Ezinkampanini ezifuna ukutshala imali ekushiseleni i-seam, izinzuzo zokukhula komkhiqizo, ubuqotho obuqinile be-weld, kanye nokuhambisana ne-automation kukwenza kube isengezo esibalulekile kunoma iyiphi inqubo yokukhiqiza.

Isikhathi sokuthumela: Oct-09-2024