Spot weldersziyimishini evame ukusetshenziswa ezimbonini ezihlukahlukene, esetshenziselwa kabanzi ukuxhuma ngokunembile nangempumelelo izingxenye zensimbi, ukuze kuqinisekiswe ukusebenza kwayo okuhle kakhulu nokuphila kwesevisi, ukuhlolwa okuvamile nokugcinwa kwemishini kubalulekile, lesi sihloko sizokhuluma ngalokho okufanele sikunake lapho ukwenza ukuhlolwa kwe-spot welder.

- Ukuphepha kuqala:Ngaphambi kokuqala noma yikuphi ukuhlola, kuyadingeka ukuqinisekisa ukuthi umshini unqanyuliwe ekunikezeni amandla ukuvimbela ukuqala ngengozi ngesikhathi sokuhlolwa. Ngaphezu kwalokho, gqoka ezifaneleizinto zokuzivikela(PPE), njengamagilavu nezibuko zokuphepha. Zivikele ezingozini ezingaba khona.

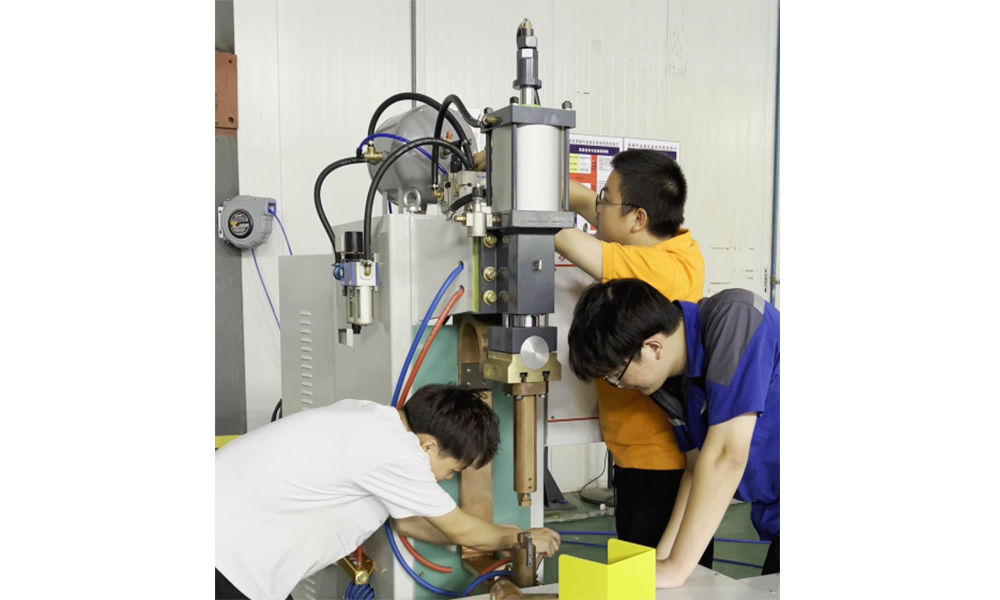

- Ukuhlola kwangaphandle:Okokuqala bheka izingxenye zangaphandle ze-welder, hlola izintambo, izixhumi, ama-electrode nezinto ezilungiswayo ukuze uthole izimpawu ezisobala zokuguga noma zokonakala, futhi uqinisekise ukuthi isimiso sokushisisa sisebenza kahle futhi ukujikeleza kokupholisa akunasici.

- Isimo se-Electrode: Isimo se-Electrode sinomthelela omkhulu kwikhwalithi yokushisela. Hlola ukuthi i-electrode inomthelela, i-deformation noma izimpawu ze-pitting, uma i-electrode ine-wear phenomenon, ingaba phansi ukuze kugcinwe ukuvumelana nokuthembeka kwe-welding.

- Ukuhlolwa kwekhebula nokuxhumana:Hlola izintambo ezishiselwe noxhumo ukuze uthole izimpawu zokulimala, ukuchayeka, noma ukuxega okuxhumekile. Ukwehluleka kwekhebula kungabangela i-arcing, okungaba yingozi futhi kuthinte ikhwalithi yokushisela.

- Ukunikezwa kwamandla nokulawula:Hlola ukunikezwa kwamandla kanye nephaneli yokulawula ukuze uthole amaphutha. Hlola ukuthi zonke izinkinobho, amaswishi, namafindo kusebenza kahle yini ukuze uqinisekise ukuthi aphendula ngendlela elindelekile.

- Isistimu yokupholisa:Isistimu yokupholisa iyadingeka ukuvimbela ukushisa ngokweqile phakathi nesikhathi eside sokusebenza. Hlola ukuthi izinga lokupholisa echibini lokupholisa livamile, futhi uhlole ukuthi umugqa wokupholisa awuvalekile yini, futhi uma kunesidingo, udinga ukuwuhlanza noma ukuwushintsha.

- I-Grounding kanye ne-insulation: Isisekelo esifanele sibaluleke kakhulu ekuphepheni kukagesi kanye nokushisela okusebenzayo. Hlola uxhumo lwaphansi futhi uqinisekise ukuthi izintambo nezintambo ziqinile futhi azigqwali ukuvimbela amasekhethi amafushane kagesi.

- Ikhwalithi yokushisela:Ukuhlolwa kokushisela kwenziwa kusampula impahla ukuze kuhlolwe ikhwalithi yokushisela nokuvumelana. Uma kutholakala noma yikuphi ukungahambi kahle, kungase kubonise inkinga ngokusethwa komshini, ama-electrode, noma ezinye izingxenye.

- Ukunakekela:Hlola ukulungiswa komshini ukuze uqinisekise ukugcinwa nokulinganisa okuvamile, okufanele ukwenze ngesikhathi ukuze ugweme ezinye izinkinga.

- Ukuhlolwa kochwepheshe:Nakuba ukuhlolwa okuvamile okubonakalayo kubalulekile, kunconywa ukuthi imishini ihlolwe njalo nguchwepheshe oqeqeshiwe. Ukuhlola okuphrofeshinali kungadalula izinkinga okungenzeka zingabonwa ngesikhathi sokuhlola okubonakalayo.Ukulawula i-welder endaweni evamile ngokuvamile kudinga ukunakekelwa ngokucophelela kuzo zonke izici, kusukela ezinyathelweni zokuphepha kuya esimweni sama-electrode, izintambo, izilawuli kanye nezinhlelo zokupholisa. Ngezilawuli eziphelele nezenziwe ngezifiso, ungathuthukisa ukusebenza futhi wandise impilo ye-welder, unciphise isikhathi sokuphumula futhi uqinisekise ukusebenza okuphephile. Kuyadingeka ezinhlelweni ezahlukahlukene zezimboni.

Ukulawula i-welder endaweni evamile ngokuvamile kudinga ukunakekelwa ngokucophelela kuzo zonke izici, kusukela ezinyathelweni zokuphepha kuya esimweni sama-electrode, izintambo, izilawuli kanye nezinhlelo zokupholisa. Ngezilawuli eziphelele nezenziwe ngezifiso, ungathuthukisa ukusebenza futhi wandise impilo ye-welder, unciphise isikhathi sokuphumula futhi uqinisekise ukusebenza okuphephile. Kuyadingeka ezinhlelweni ezahlukahlukene zezimboni.

Isikhathi sokuthumela: Aug-20-2024